InstallingtheBattery

1.Positionthebatteryinthetray(Figure36).

2.Installthepositive(red)batterycabletothepositive(+)

batteryterminalusingthefastenersremovedpreviously.

3.Installthenegativebatterycabletothenegative(-)

batteryterminalusingthefastenersremovedpreviously.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(

Figure36).

6.Lowertheseat.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fuse:

•MainF1-30amp,blade-type

•ChargeCircuitF2-25amp,blade-type

1.Removethescrewssecuringthecontrolpaneltothe

machine.Retainallfasteners

2.Liftthecontrolpaneuptoaccessthemainwiring

harnessandfuseblock(

Figure38).

3.Toreplaceafuse,pulloutonthefusetoremoveit

(Figure38).

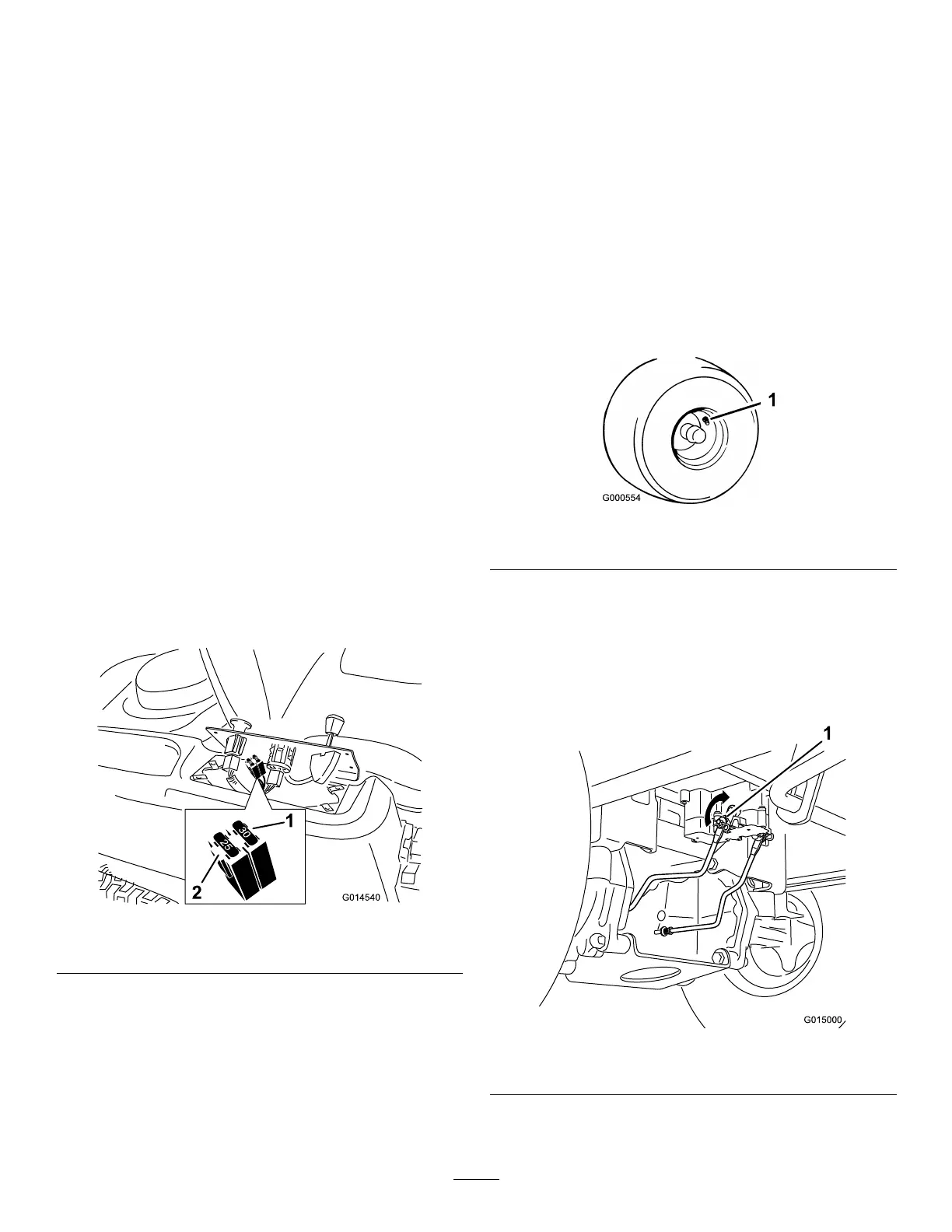

Figure38

1.Main-30amp

2.Chargecircuit-25amp

4.Returnthecontrolpaneltoitsoriginalposition.Use

thescrewsremovedpreviouslytosecurethepanelto

themachine.

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure39).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto12psi.

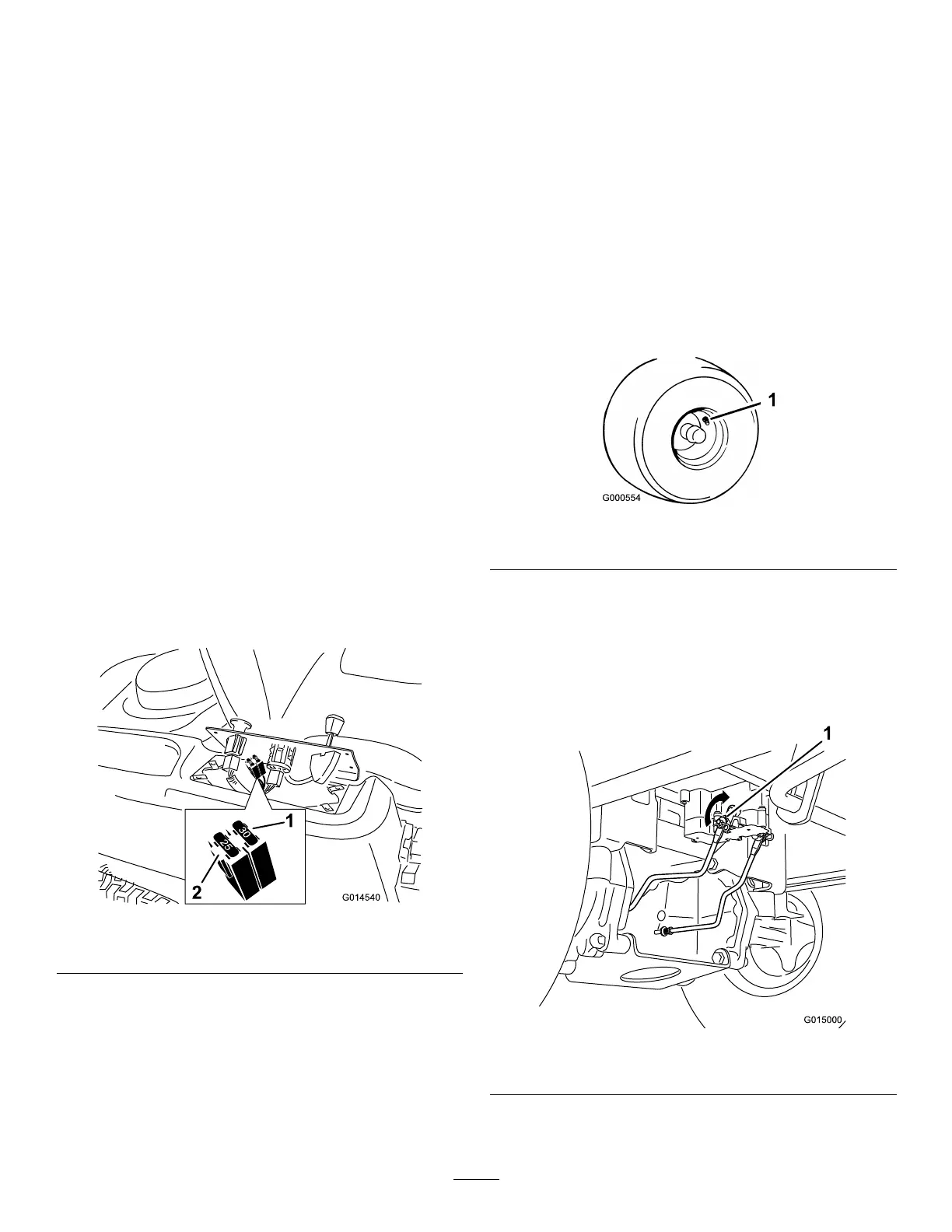

Figure39

1.Valvestem

ReleasingtheElectricBrake

Theelectricbrakecanbereleasebymanuallyrotatingthe

linkarmsforward.Oncetheelectricbrakeisenergizedthe

brakewillreset.

Toreleasethebrake:

Figure40

1.Brakelinkarmontheelectricbrakecontrolmodule

1.Locatetheshaftontheelectricbrakewherethebrake

linkarmsareconnected.

29

Loading...

Loading...