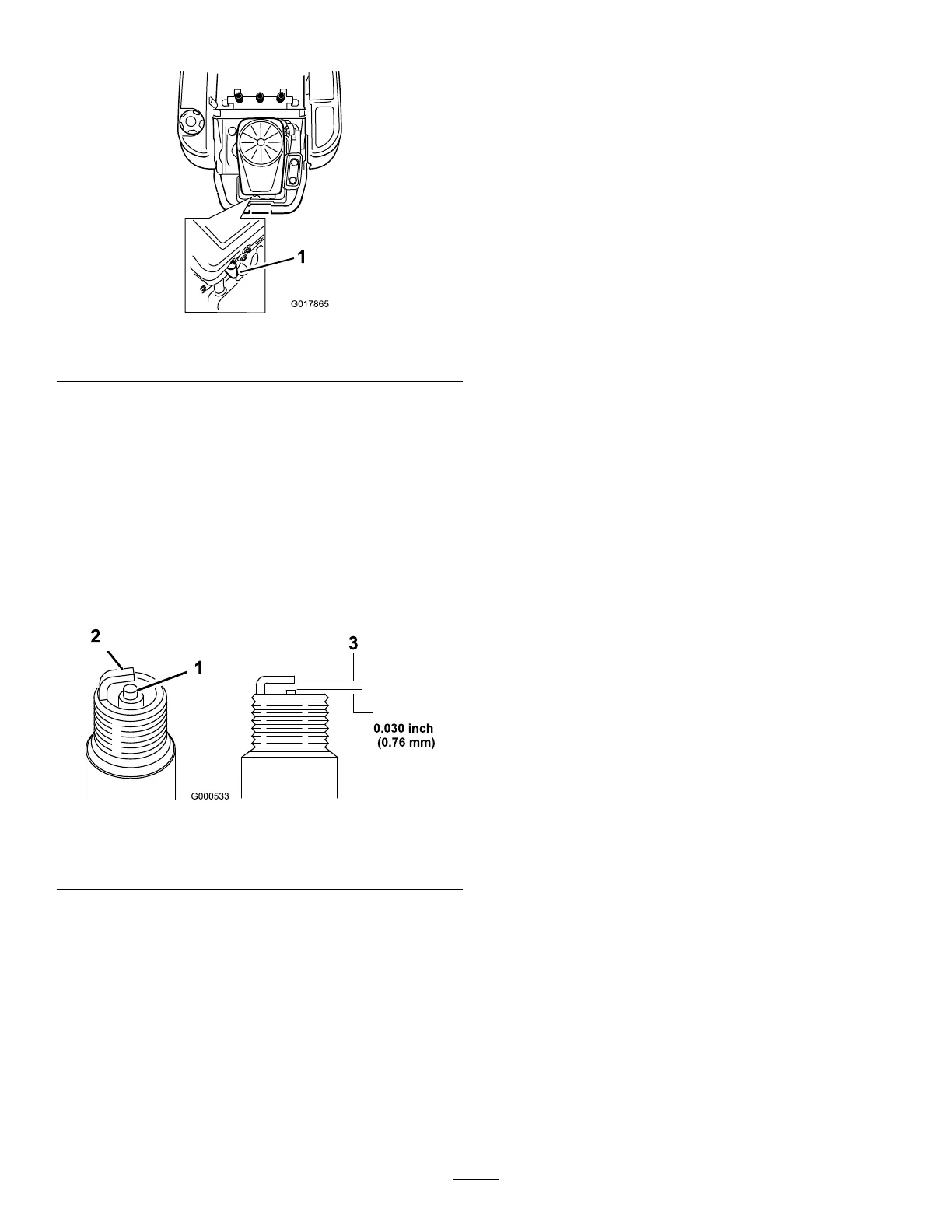

3.Disconnectthewirefromthesparkplug(Figure33).

Figure33

1.Spark-plugwire

4.Cleanaroundthesparkplugtopreventdirtfromfalling

intotheengineandpotentiallycausingdamage.

5.Removethesparkplugandmetalwasher.

CheckingtheSparkPlug

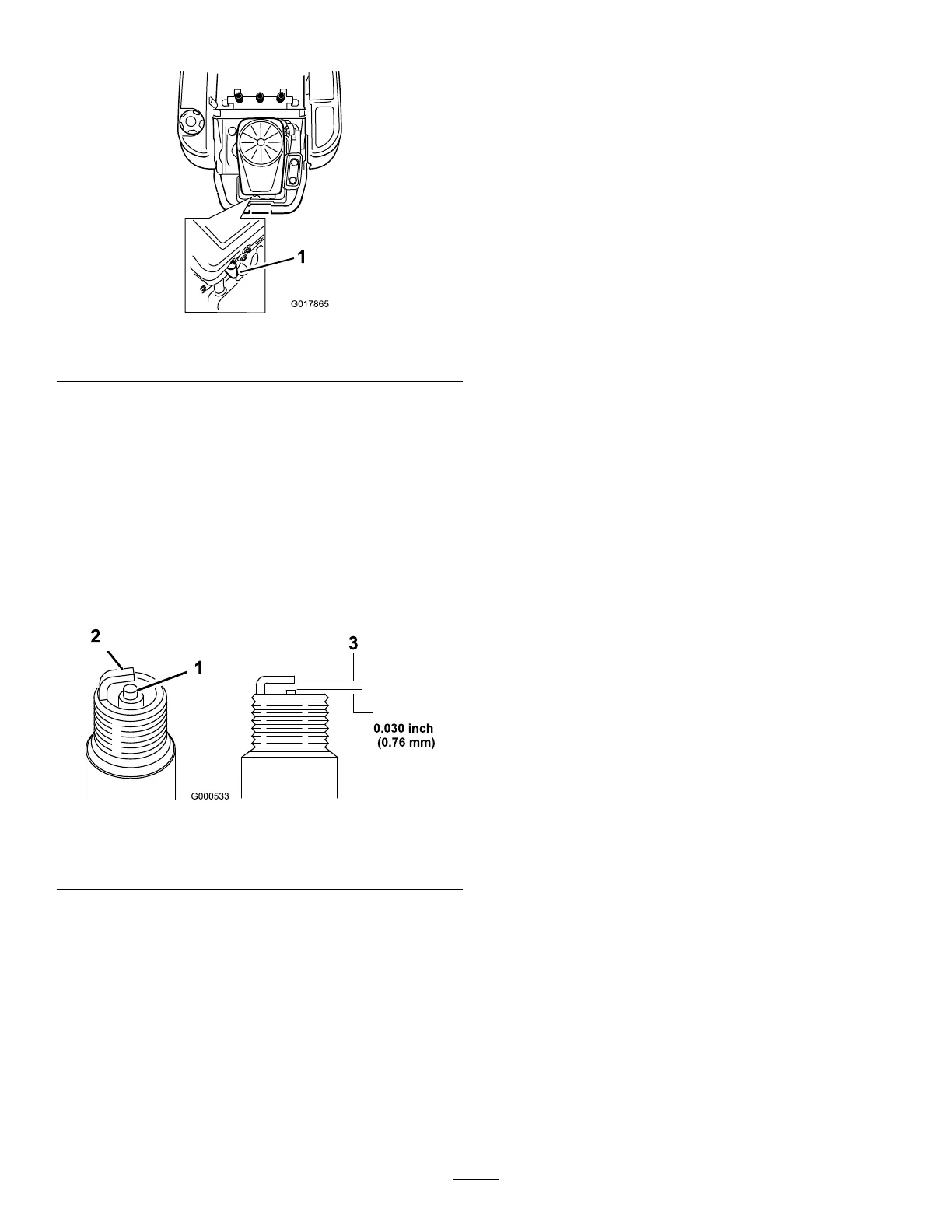

1.Inspectthesparkplug(Figure34).

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

Figure34

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(

Figure34).Bendthesideelectrodeifthegapisnot

correct.

InstallingtheSparkPlug

1.Installthesparkplugandmetalwasher.

Note:Ensurethattheairgapissetcorrectly.

2.Tightenthesparkplugto15ft-lb(20N-m).

3.Connectthewiretothesparkplug.

CleaningtheBlowerHousing

Toensurepropercooling,makesurethegrassscreen,cooling

ns,andotherexternalsurfacesoftheenginearekeptclean

atalltimes.

Annuallyorevery100hoursofoperation(moreoftenunder

extremelydusty,dirtyconditions),removetheblowerhousing

andanyothercoolingshrouds.Cleanthecoolingnsand

externalsurfacesasnecessary.Makesurethecoolingshrouds

arereinstalled.Torquetheblowerhousingscrewsto5.5ft-lb

(7.5N-m).

Important:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,and/orcooling

shroudsremoved,willcauseenginedamagedueto

overheating.

26

Loading...

Loading...