EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

cleanerfordirty,looseordamagedparts.

Every50hours—Servicethepaperelement(more

oftenunderextremelydusty,dirtyconditions).

Every100hours—Replacethepaperelement(more

oftenunderextremelydusty,dirtyconditions).

Thisengineisequippedwithareplaceable,highdensitypaper

air-cleanerelement.Checktheaircleanerdailyorbefore

startingtheengine.Checkforabuildupofdirtanddebris

aroundtheair-cleanersystem.Keepthisareaclean.Also,

checkforlooseordamagedcomponents.Replaceallbentor

damagedair-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairintothe

engine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunderextremely

dusty,dirtyconditions.

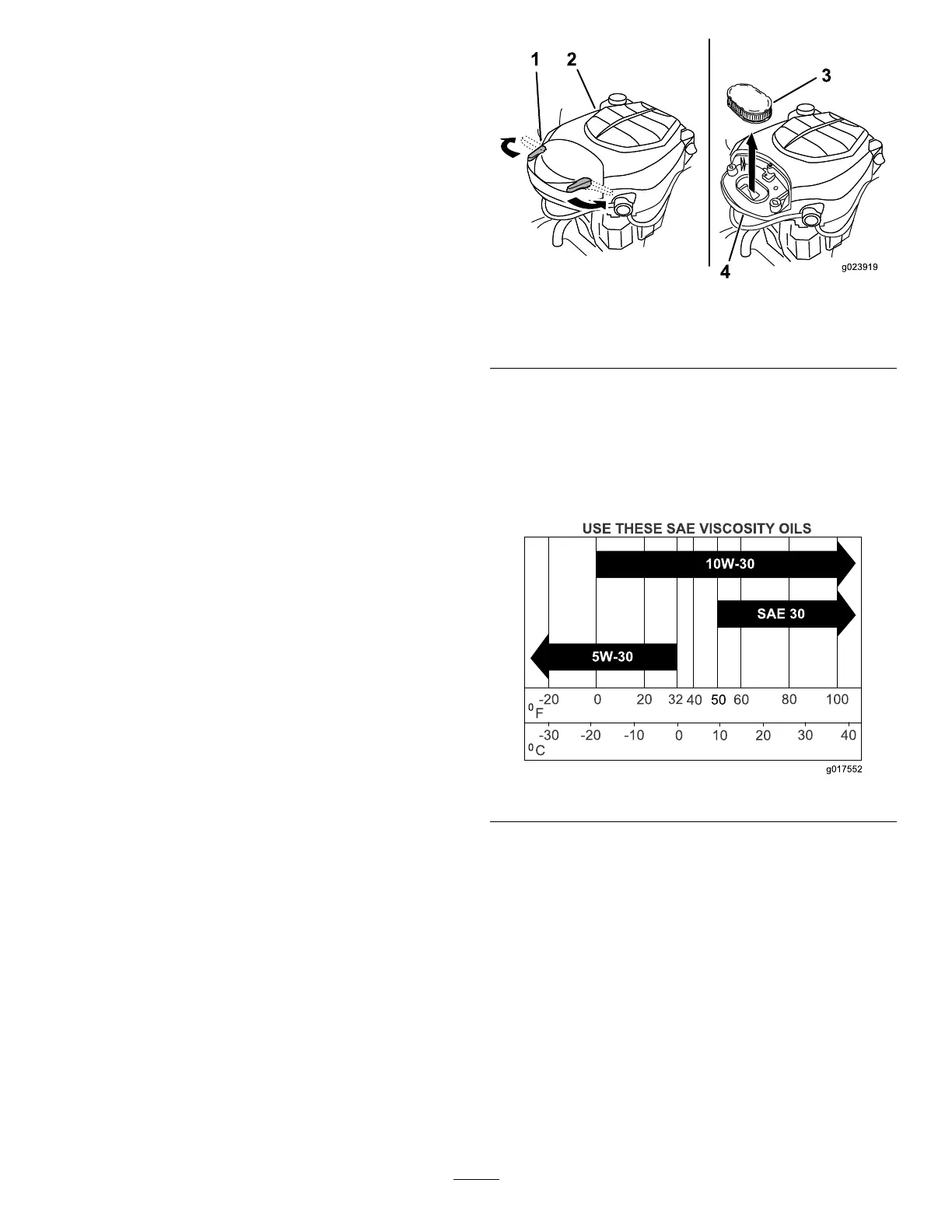

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleanerelement

(Figure27).

3.Removetheelement,andgentlytaptheelementto

dislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseifthe

sealingsurfacesarebentordamaged.

4.Cleantheair-cleanerbaseasrequired,andcheckthe

condition.

5.Installthepaperelementontotheair-cleanerbase.

6.Installthecover,andsecureitwiththelatches(Figure

27).

Figure27

1.Air-cleanerlatch3.Paperelement

2.Engine4.Air-cleanerbase

ServicingtheEngineOil

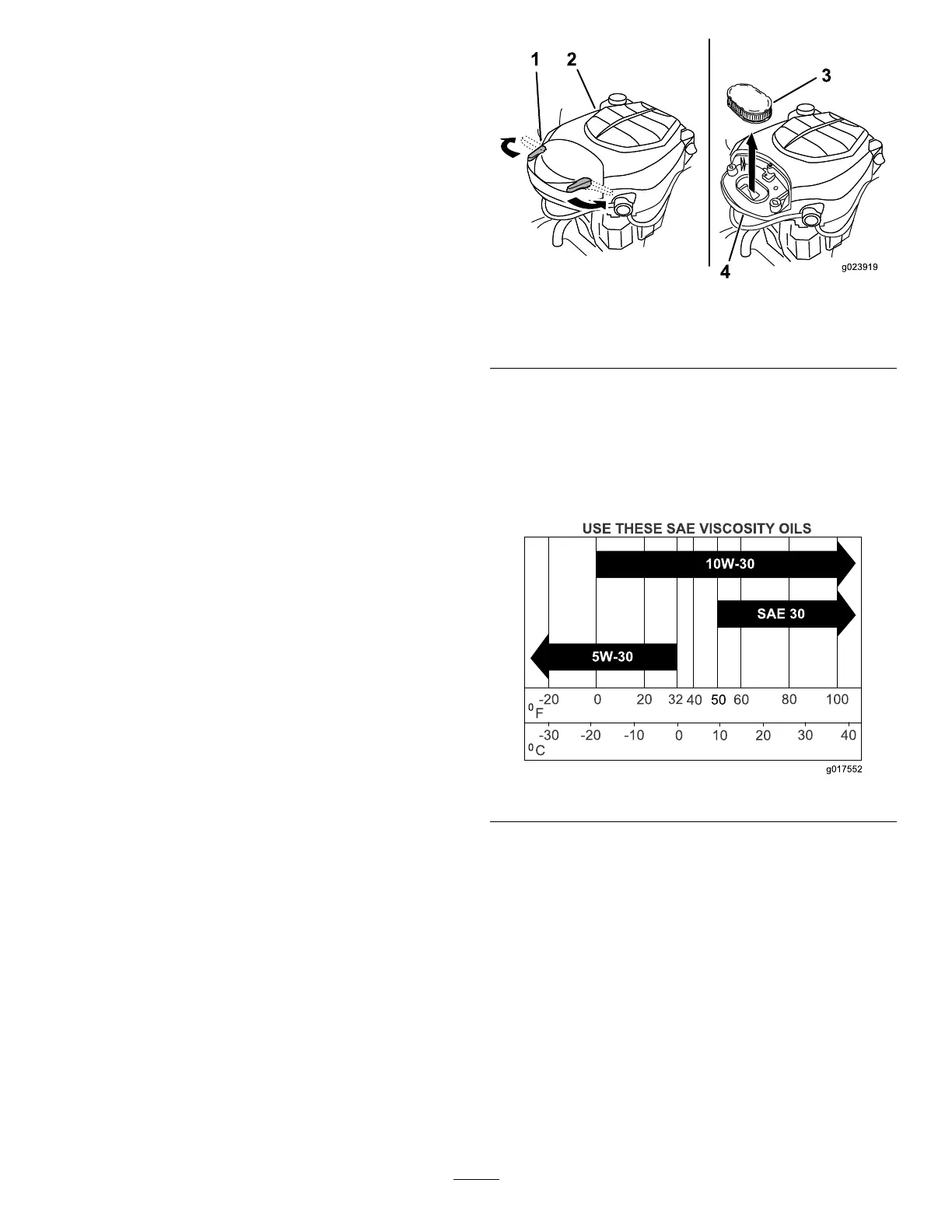

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelterischanged

Viscosity:Seethetablebelow.

Figure28

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,stoptheengine,andremovethe

key.

2.Makesuretheengineisstopped,level,andiscool,so

theoilhashastimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoil-llcap/dipstickbefore

removingit.

4.Removethedipstick;wipetheoiloff(

Figure29).

5.Insertthedipstickintothetube.

24

Loading...

Loading...