Figure48

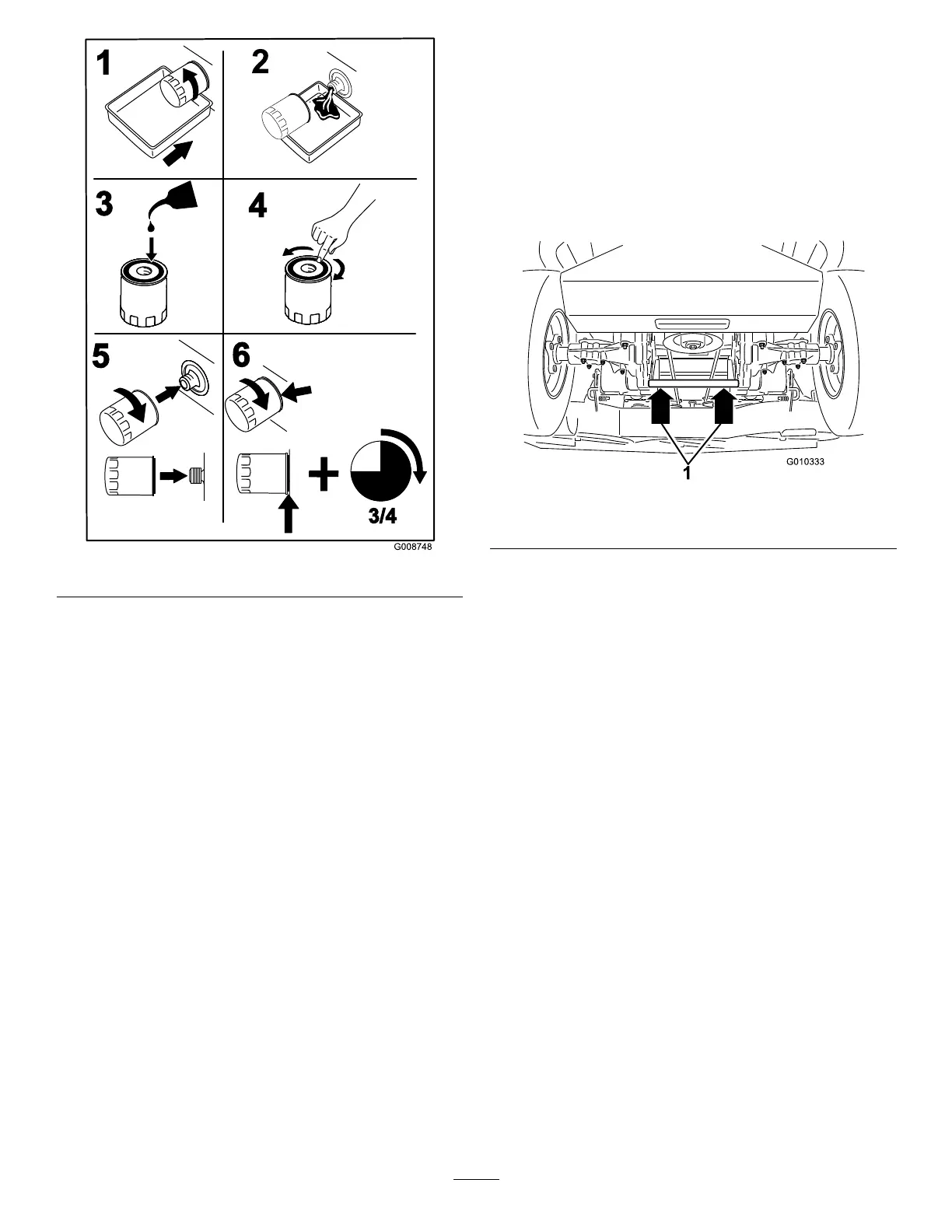

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4

to1fullturn.

3.Repeatfortheotherlter

4.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

5.Verifytheventplugsareremovedbeforeaddingtheoil.

6.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.

7.Installtheventplug.Torquetheplugto20.3N-m

(180in-lb).

8.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.

9.Installtheventplug.Torquetheplugto20.3N-m

(180in-lb).

10.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineontheexpansion

reservoir.ProceedtotheBleedingtheHydraulic

Systemsection.

Important:Failuretoperformthe

Bleeding

the Hy draulic System

procedureafterchanging

hydraulicltersandoilmayresultinirreparable

damagetothetransaxledrivesystem.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

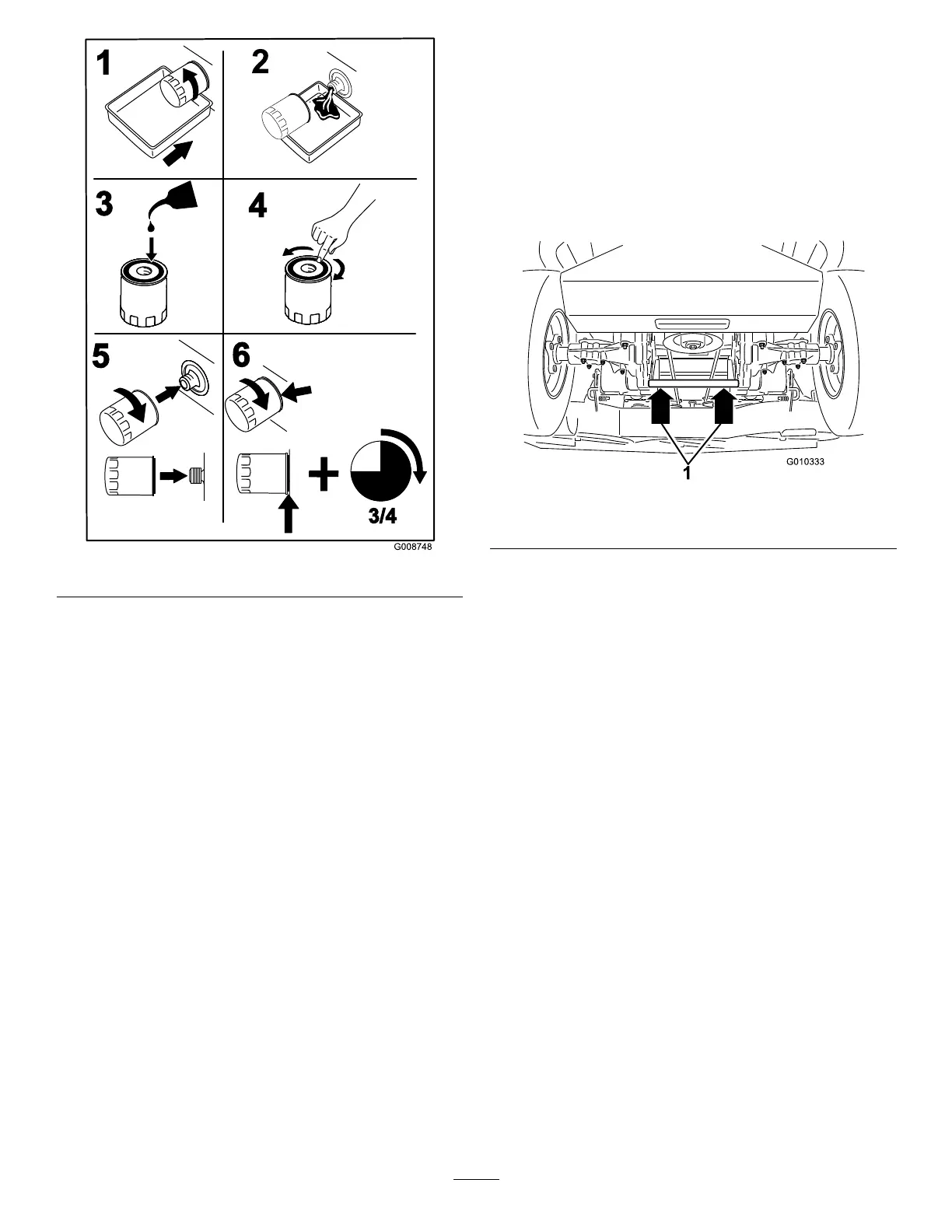

Figure49

1.Jackingpoints

2.Gototheoperator'sposition.Starttheengineand

movethrottlecontrolaheadto1/2throttleposition.

Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.Withthe

bypassvalvesopenandtheenginerunning,slowly

movethemotioncontrolleversinbothforward

andreverse(5or6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilasuntil

itreachestheFULLCOLDlineontheexpansion

reservoir.

3.Repeatstep2untilalltheairiscompletelypurgedfrom

thesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

4.Checktheoillevelintheexpansionreservoironelast

time.AddthespeciedoilasuntilitreachestheFULL

COLDlineontheexpansionreservoirifnecessary.

37

Loading...

Loading...