3.Measurefromthetipofthebladetotheatsurface

here.

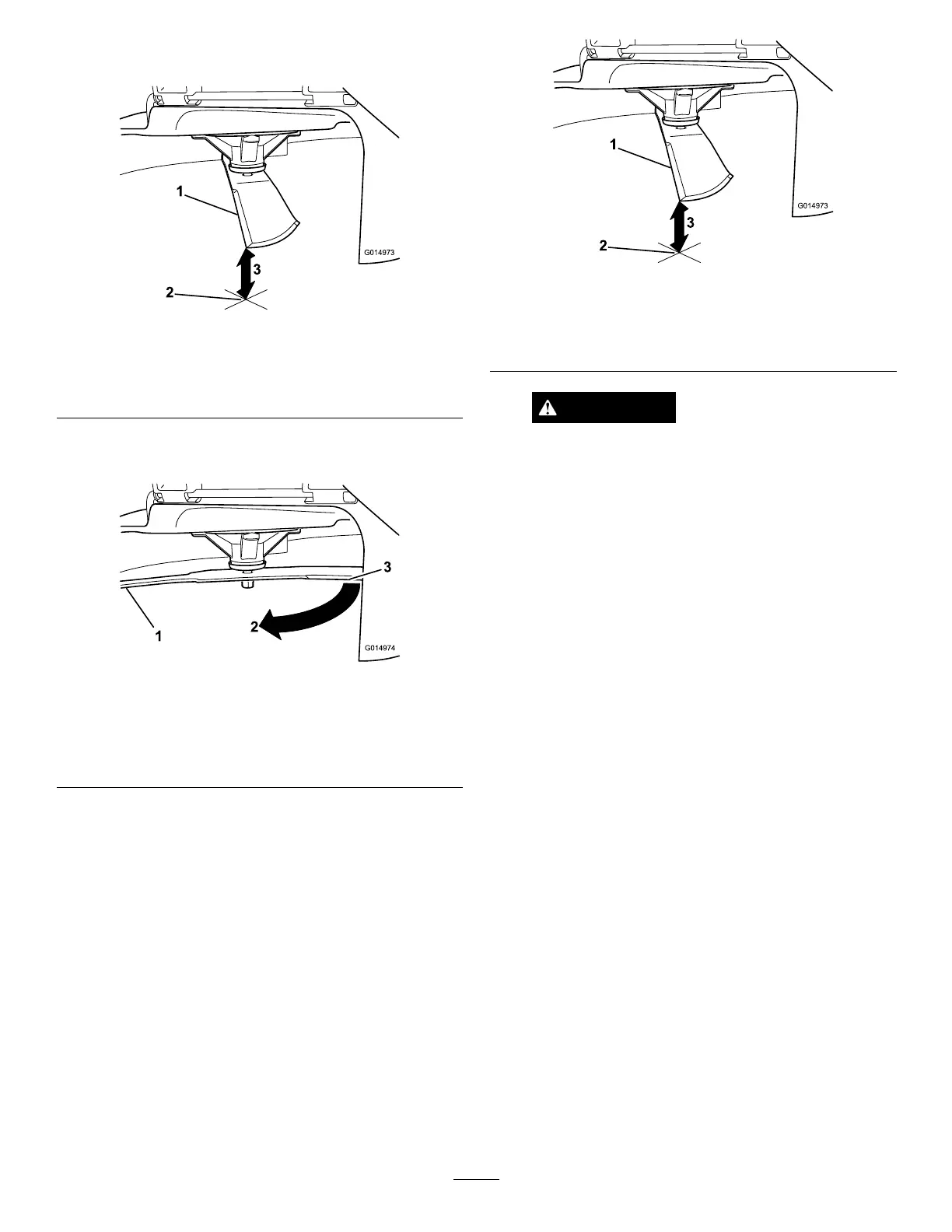

Figure52

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition.

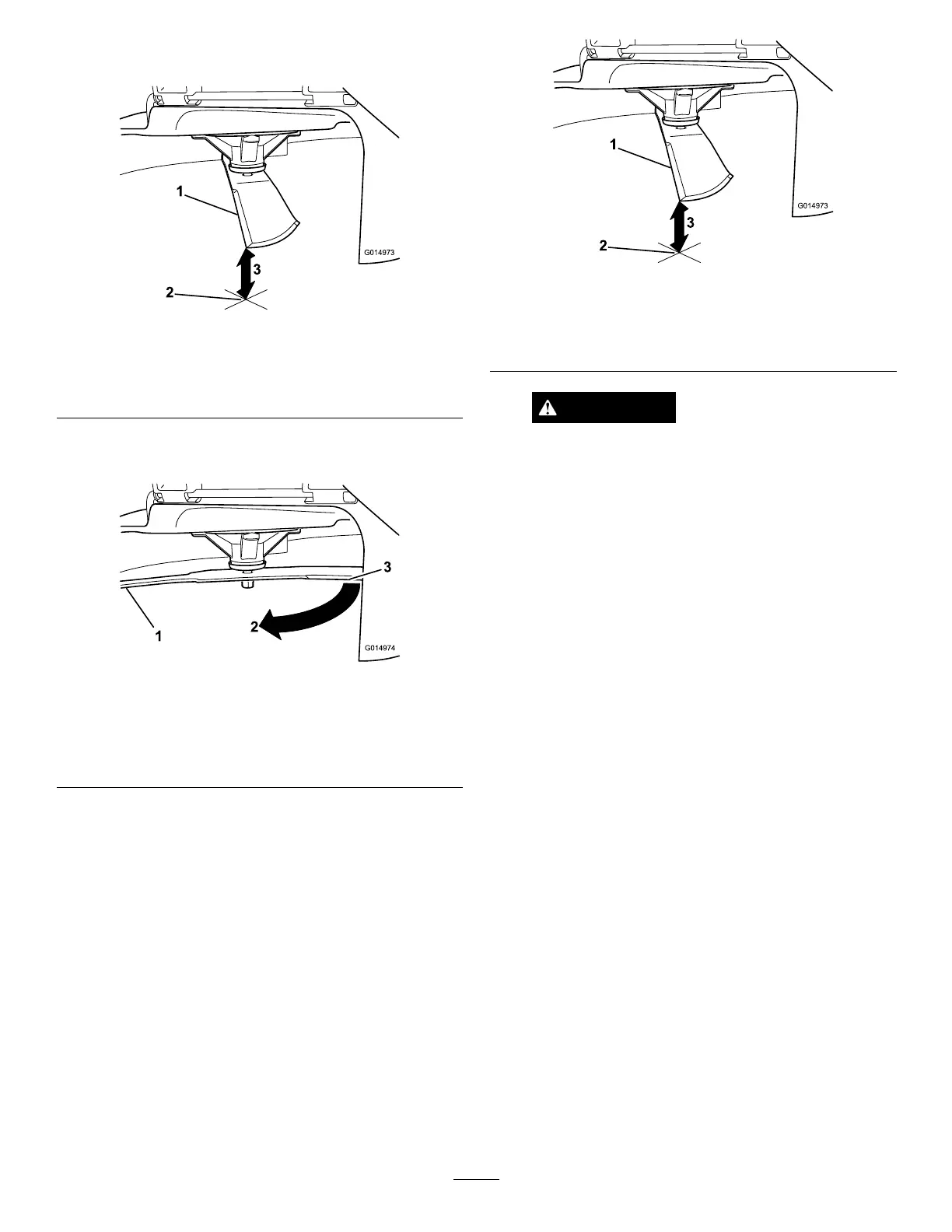

Figure53

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan3mm(1/8

inch).

Figure54

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesoftheblade.

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch)replacethebladewithanew

blade.Referto

RemovingtheBlades(page39)

andInstallingtheBlades(page40).

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed3

mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

6.Repeatthisprocedureoneachblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineTororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt(rotatingitcounter-clockwise),curved

washer,andbladefromthespindleshaft(

Figure55).

39

Loading...

Loading...