ChangingtheHydraulic

FluidandFilters

ServiceInterval:Aftertherst75hours—Changethe

hydraulic-systemltersanduid.

Every400hours—Aftertheinitial

change—changethehydraulic-system

ltersanduidwhenusingT oro

®

HYPR-OIL

™

500uid.(Changeitmoreoftenunderdirtyor

dustyconditions)

Toreplacethehydraulicuid,theltersneedtobe

removed.Replacebothatthesametime;referto

Hydraulic-FluidSpecications(page66)foruid

specications.

Purgeanyairinthesystemafteryouinstallthenew

ltersandadduid;refertoBleedingtheHydraulic

System(page68).Repeatthebleedingprocessuntil

theuidremainsattheFULLCOLDlineinthereservoir

afterpurging.Failuretoproperlyperformthis

procedurecanresultinirreparabledamagetothe

transaxledrivesystem.

RemovingHydraulic-System

Filters

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Allowtheenginetocool.

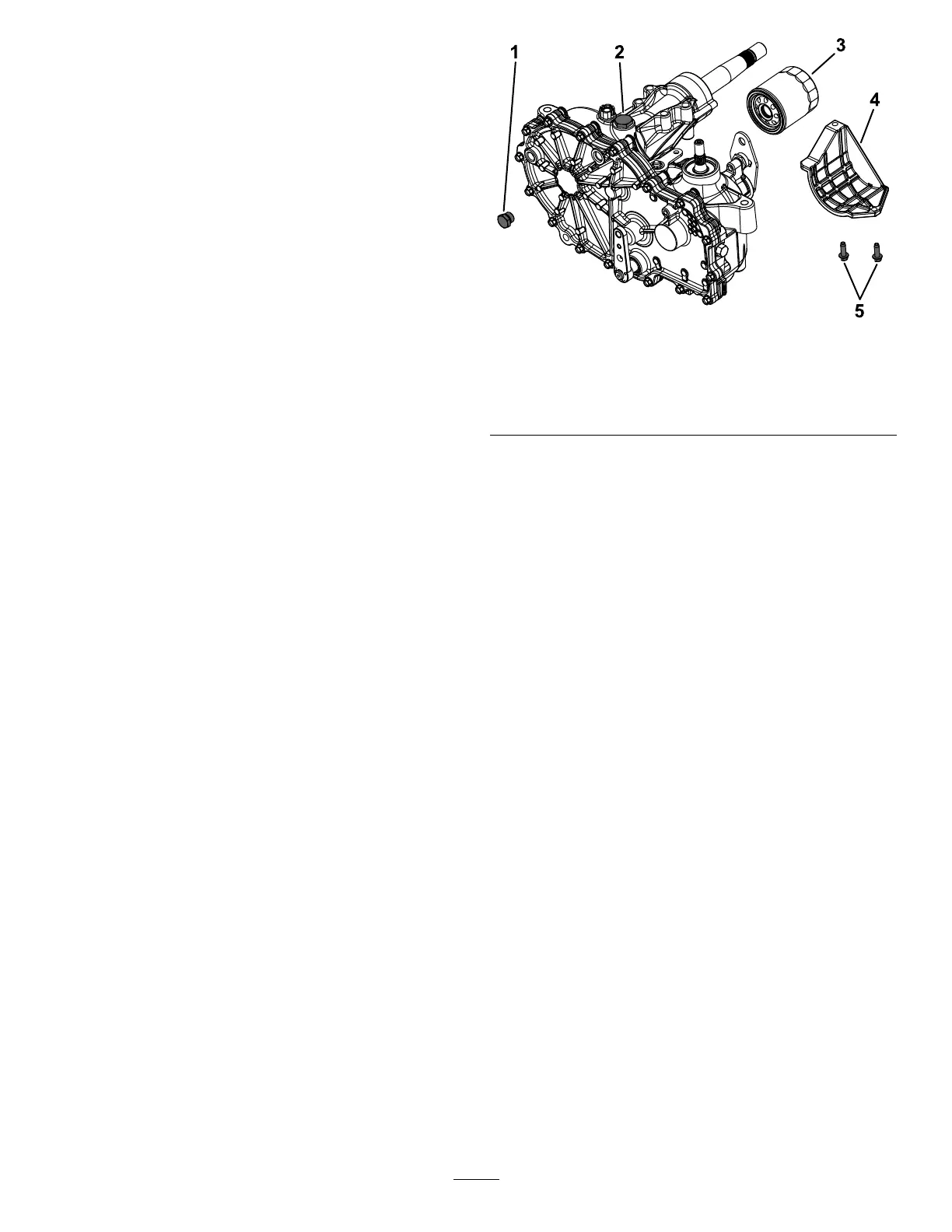

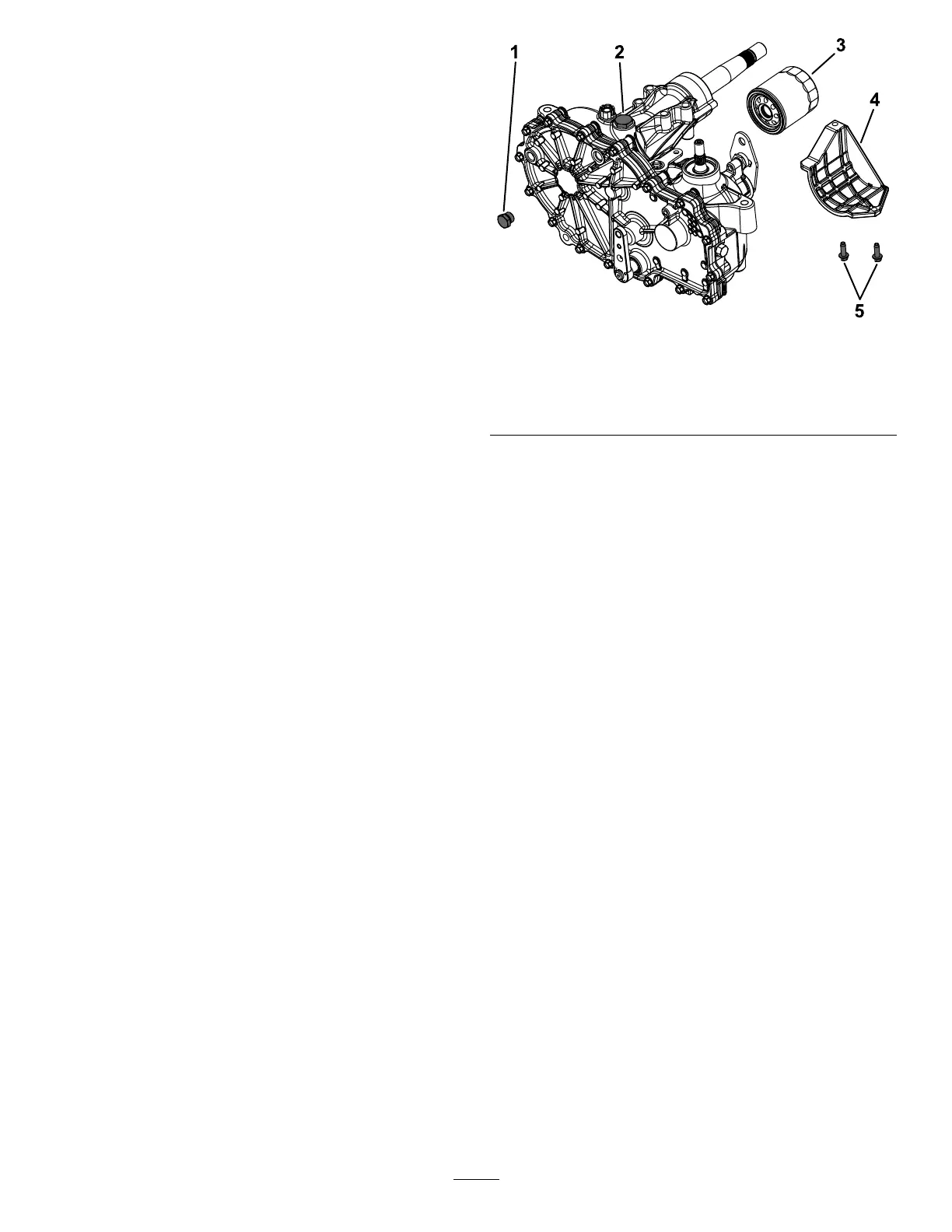

4.Locatethelterandguardsoneach

transaxle-drivesystem(Figure91).

5.Removethe3screwssecuringthelterguard

andguard(Figure91).

g413064

Figure91

1.Topportplug4.Filterguard

2.Fillportplug

5.Screws

3.Filter

6.Carefullycleantheareaaroundthelters.

Important:Donotallowdirttoenterthe

hydraulicsystem,orcontaminationmay

occur.

7.Placeadrainpanbelowtheltertocatchthe

uidthatdrainswhenthelterandventplugs

areremoved.

8.Locateandremovetheventplugoneach

transmission.

9.Unscrewtheltertoremoveit,andallowthe

uidtodrainfromthedrivesystem.

10.Repeatthisprocedureforbothlters.

InstallingtheHydraulic-System

Filters

1.Applyathincoatofhydraulicuidonthesurface

oftherubbersealofeachlter.

2.Turnthelterclockwiseuntiltherubberseal

contactsthelteradapter,thentightenthelter

anadditional3/4to1fullturn.

3.Repeatfortheoppositelter.

4.Installthelterguardsovereachlterthatyou

previouslyremoved.

5.Usethe3screwstosecurethelterguards.

6.Verifythattheventplugsareremovedbefore

addingtheuid.

7.Removethetopportplug(Figure91)fromthe

leftsideandrightsidetransaxlespriortolling

withoil.

Thiswillallowthetransaxlestoventduringoilll.

67

Loading...

Loading...