DriveSystem

Maintenance

AdjustingtheTracking

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullsto1side.

Note:Ifitdoes,stopthemachineandsettheparking

brake.

3.Releasethecushionfromtherearofthemachine;refer

toReleasingtheCushionforRearAccess(page28).

Note:Foreasieraccess,youcanalsoremovethefuel

tank;refertoRemovingtheFuelTank(page35).

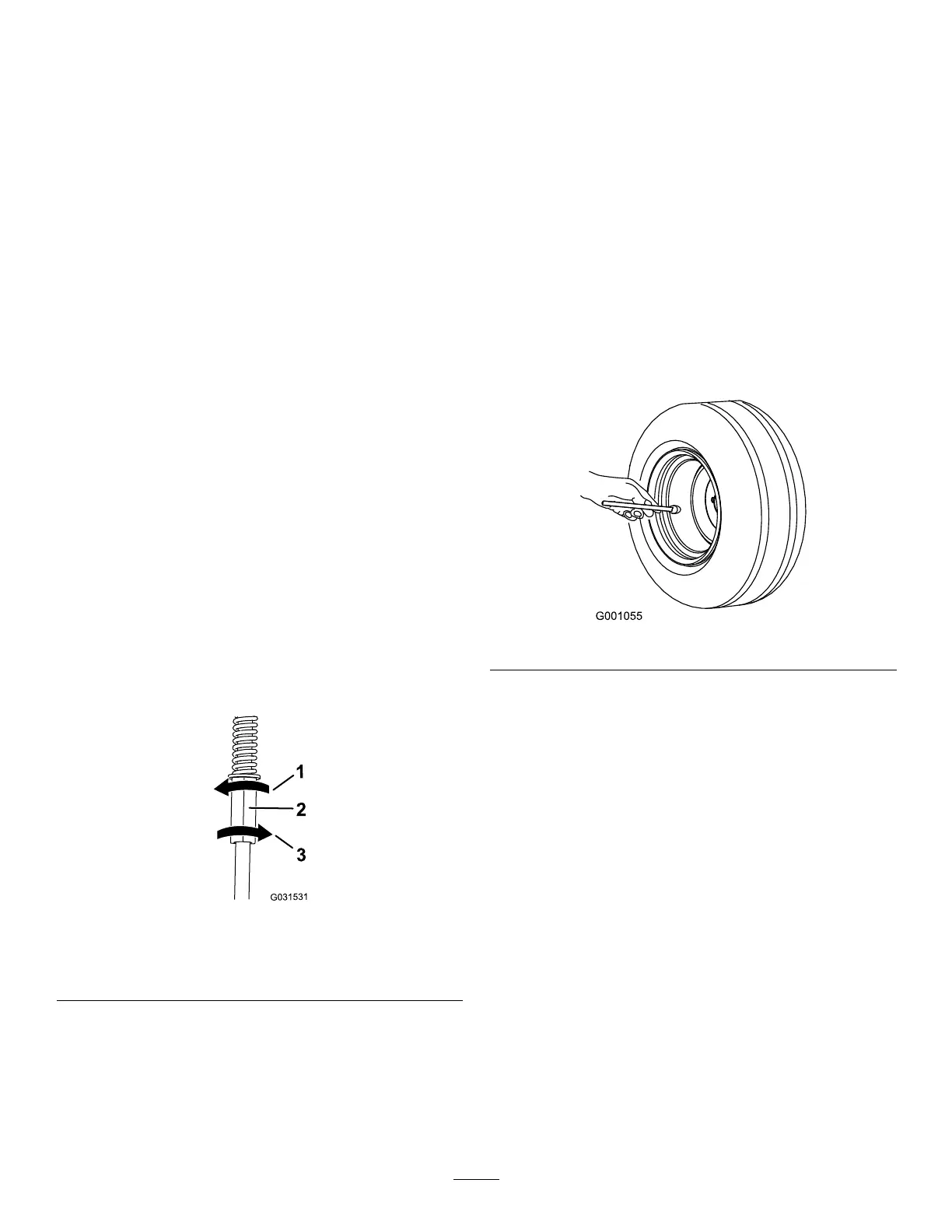

4.Rotatetheleftcontrolrodinquarter-turnincrements

untilthemachinetracksstraight(Figure51).

Note:Ifthemachinepullstotheright,shortenthe

controlrodbyrotatingittotheright.Ifthemachine

pullstotheleft,lengthentherodbyrotatingittothe

left.

Note:Onlyadjusttheleftcontrolrodtomatchthe

leftwheelspeedtotherightwheelspeed.Donot

adjusttherightwheelspeed,asthispositionstheright

motion-controlleveroutofthecenterforthecontrol

panelneutral-lockslot.

Important:Donotrotatethecontrolrodtoofar,

asthismaycausethemachinetocreepinneutral.

Figure51

1.Rotatelefttolengthenthe

rod.

3.Rotaterighttoshortenthe

rod.

2.Leftcontrolrod

5.Checkforpropertracking,andadjusttherodas

necessary.

Note:Ifyouareunabletoachievepropertrackingby

adjustingtheleftcontrolrod,contactyourAuthorized

ServiceDealer.

6.Checkthatthemachinedoesnotcreepfromthe

neutralpositionwiththeparkbrakesdisengaged.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

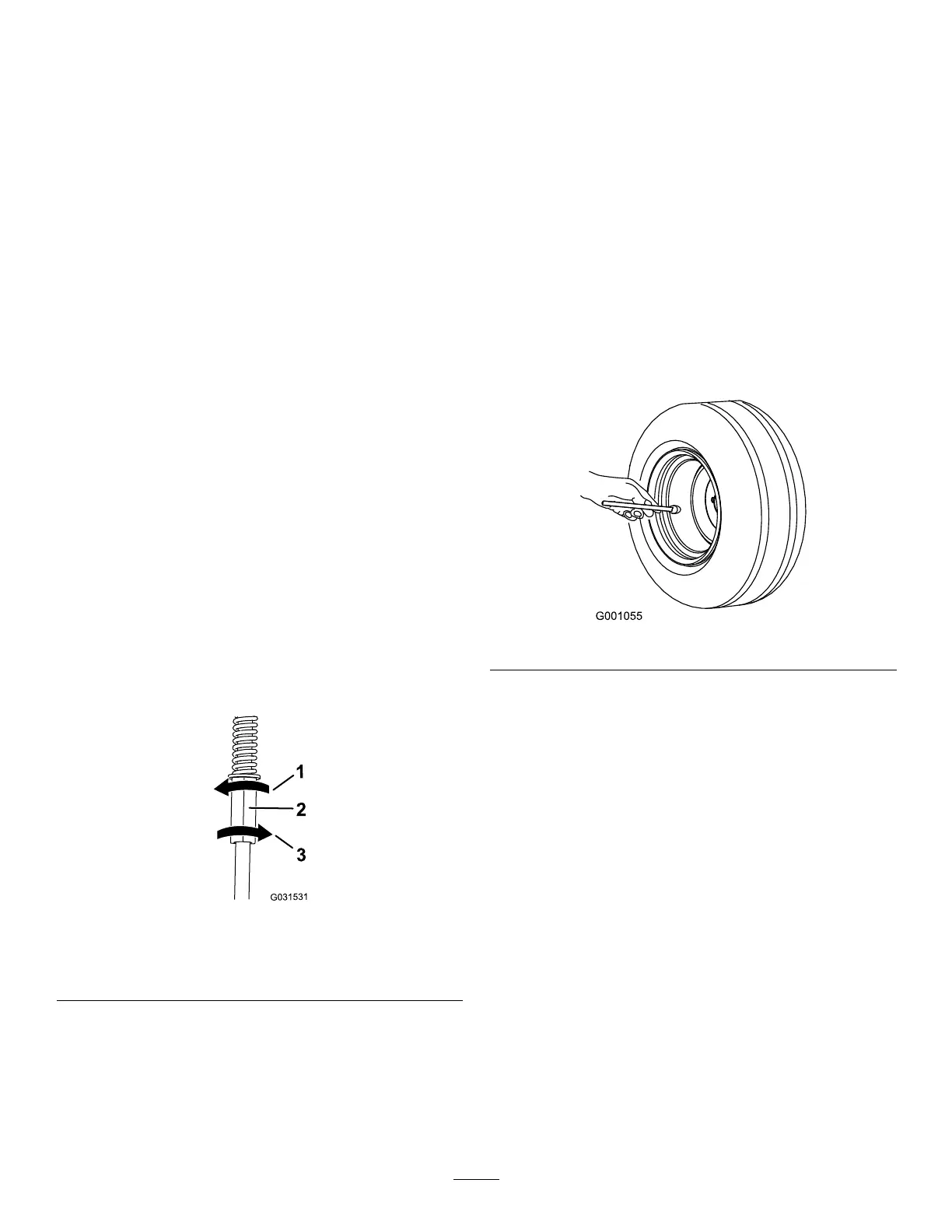

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).

Important:Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireair-pressuremaintenance.

Figure52

39

Loading...

Loading...