72

MAINTENANCE

3. Remove screw and replace the valve cone.

4. Inspect or replace two O-Ring's located on

Piston.

5. Replace the O-Ring's on the exterior of the

Housing.

6. Reassemble in opposite sequence.

7. Retest per inspection procedure.

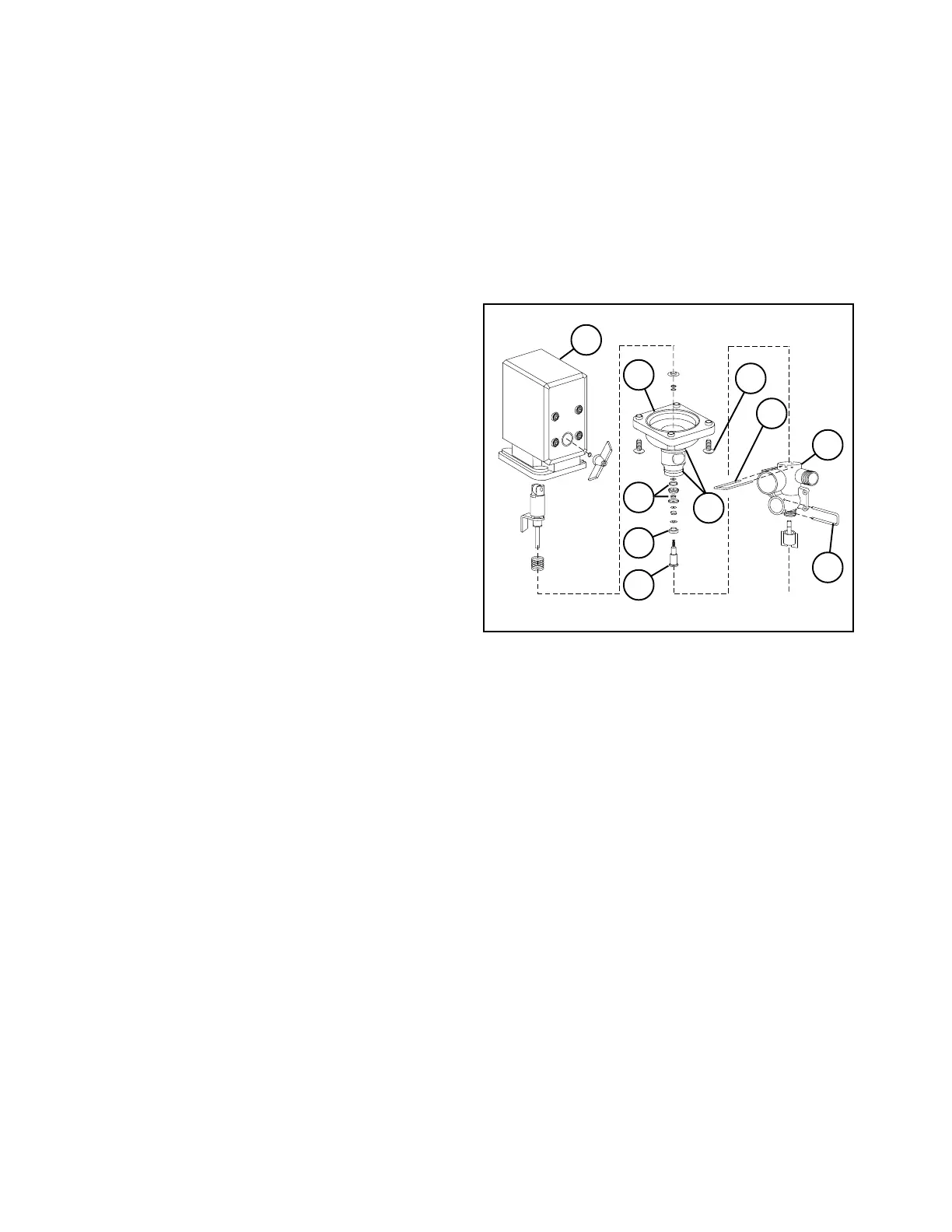

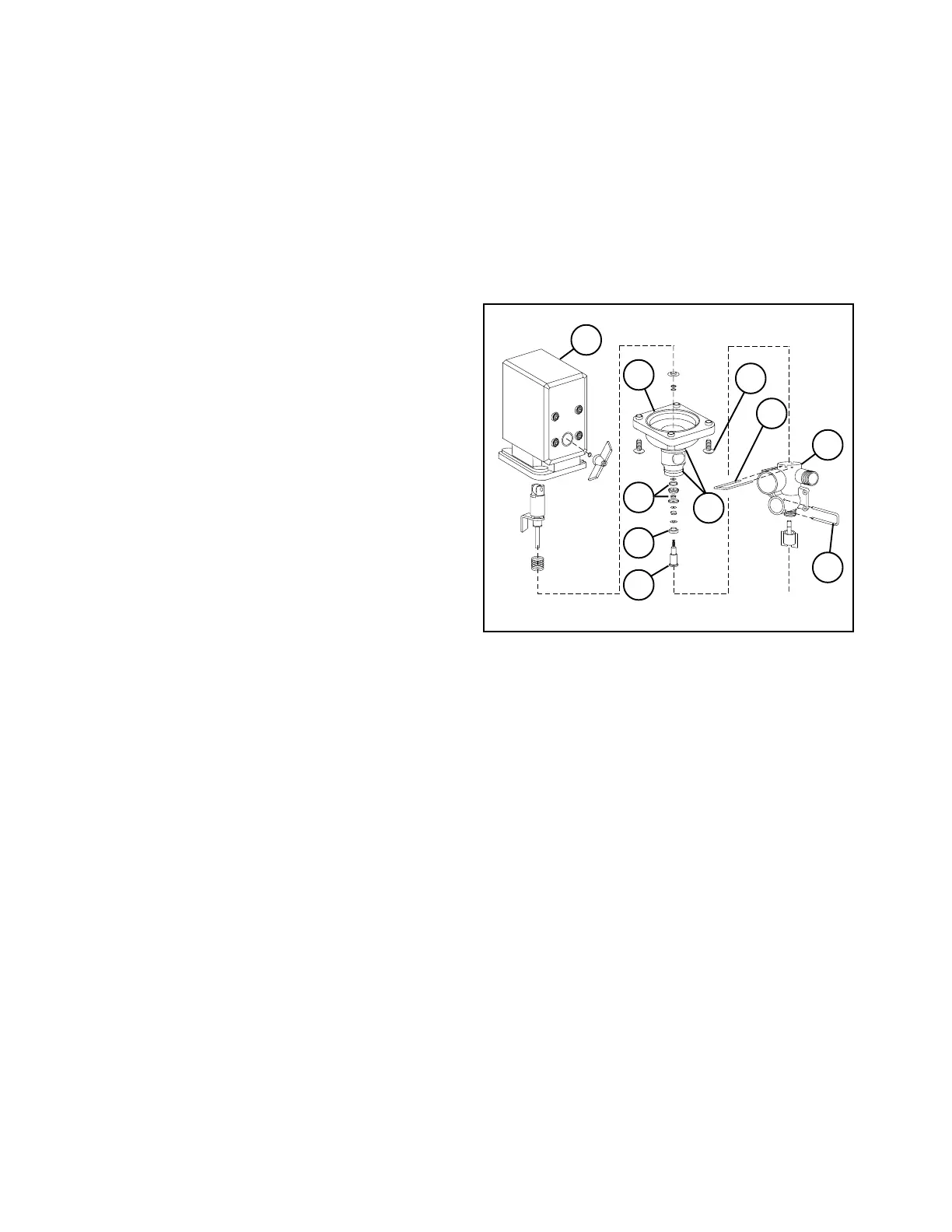

FIG. 8

1. Fork 6. O-Rings

2. Housing 7. Screw

3. Valve Cone 8. Housing ASM

4. Fork, Motor ASM 9. Motor Unit

5. Screw 10. O-Rings

FLOWMETER (SEE FIG. 7, page 71):

The Flowmeter may need to be disassembled for

periodic cleaning or to remove an obstruction.

Disconnect the signal wire and remove the

retaining cap by unscrewing it from the body. Pull

the Paddle Wheel assembly from the housing.

Once disassembled, use warm water and if

necessary, a mild detergent and soft bristled

brush to clean all parts. DO NOT USE

SOLVENTS OR DIESEL FUEL TO CLEAN THE

FLOWMETER. A magnet should work well for

removing fine metallic particles from the turbine.

Inspect all parts. Check for excessive bearing or

shaft wear. When assembling Flowmeter into

Housing, align Flowmeter Pin to hole on top of

Housing.

SPRAY PRO

MONITOR:

Store the monitor in a cool dry location if it will

not be used for an extended period of time, such

as during the off-season.

BOOM CONTROL VALVE:

IMPORTANT: Before performing any

maintenance, make sure electrical power to

the Boom Control Valve is shut off and this will

relieve line pressure.

Keep all electrical connections and motor

clean at all times.

A protective coating may be applied to the

completed electrical connections, if desired.

INSPECT VALVE CONE AND O-RING'S:

See parts drawing (FIG. 8) for reference.

1. Flush the sprayer with clean water and open

all Boom Control Valves. Shut sprayer engine

OFF.

2. Remove fork and remove hose for the Boom

Bypass valves. When the housing is drained

make sure everything is clear from the hose.

3. Start the sprayer. There should not be any

flow of liquid through the Boom Bypass passage.

If there is any leakage, the valve cone must be

changed. Shut sprayer engine OFF.

REPLACE VALVE CONE AND O-RING'S:

1. Disconnect 2-Pin electrical terminal.

2. Remove fork and pull the motor assembly off

the valve housing.

1

1795

3

4

5

7

6

10

9

2

8

Loading...

Loading...