77

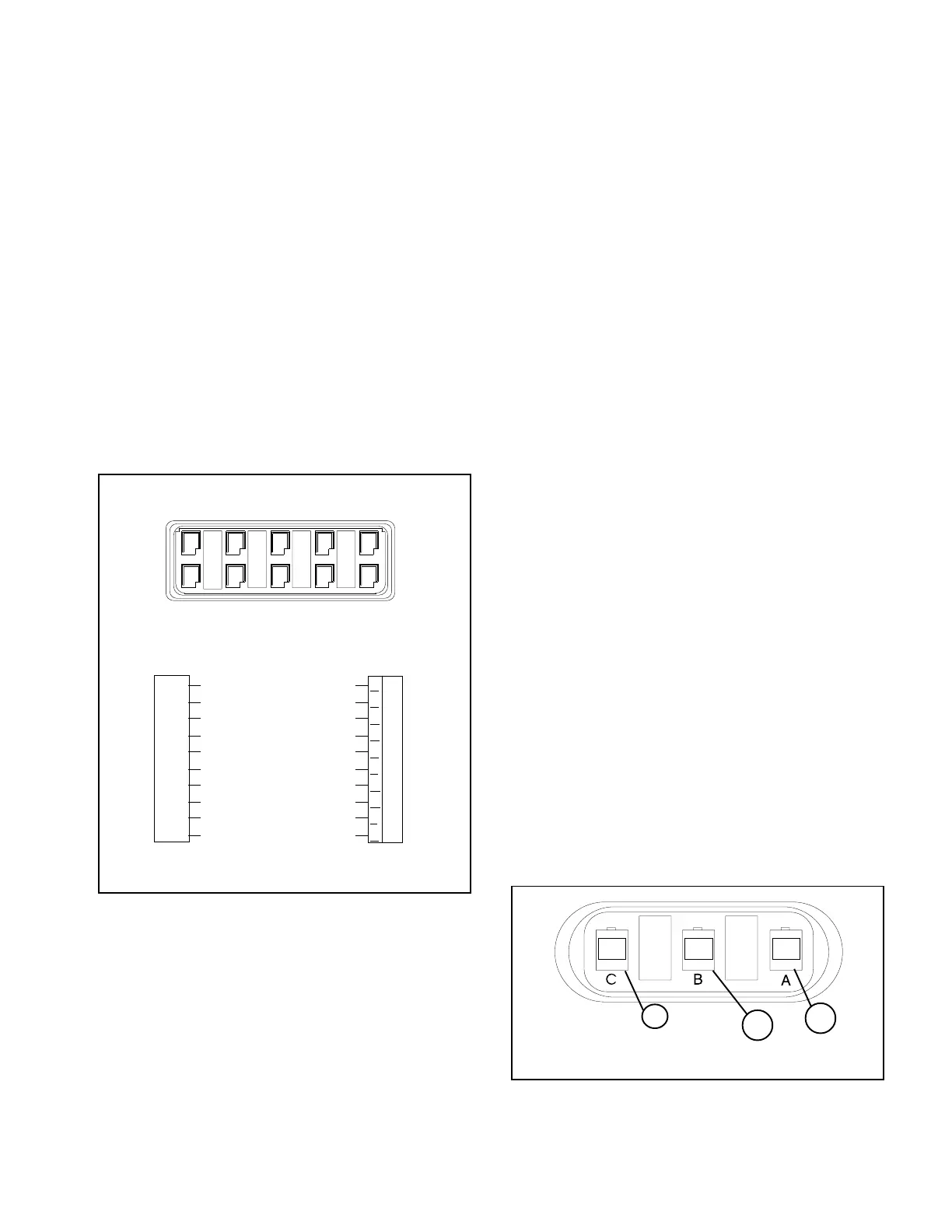

FIG. 2

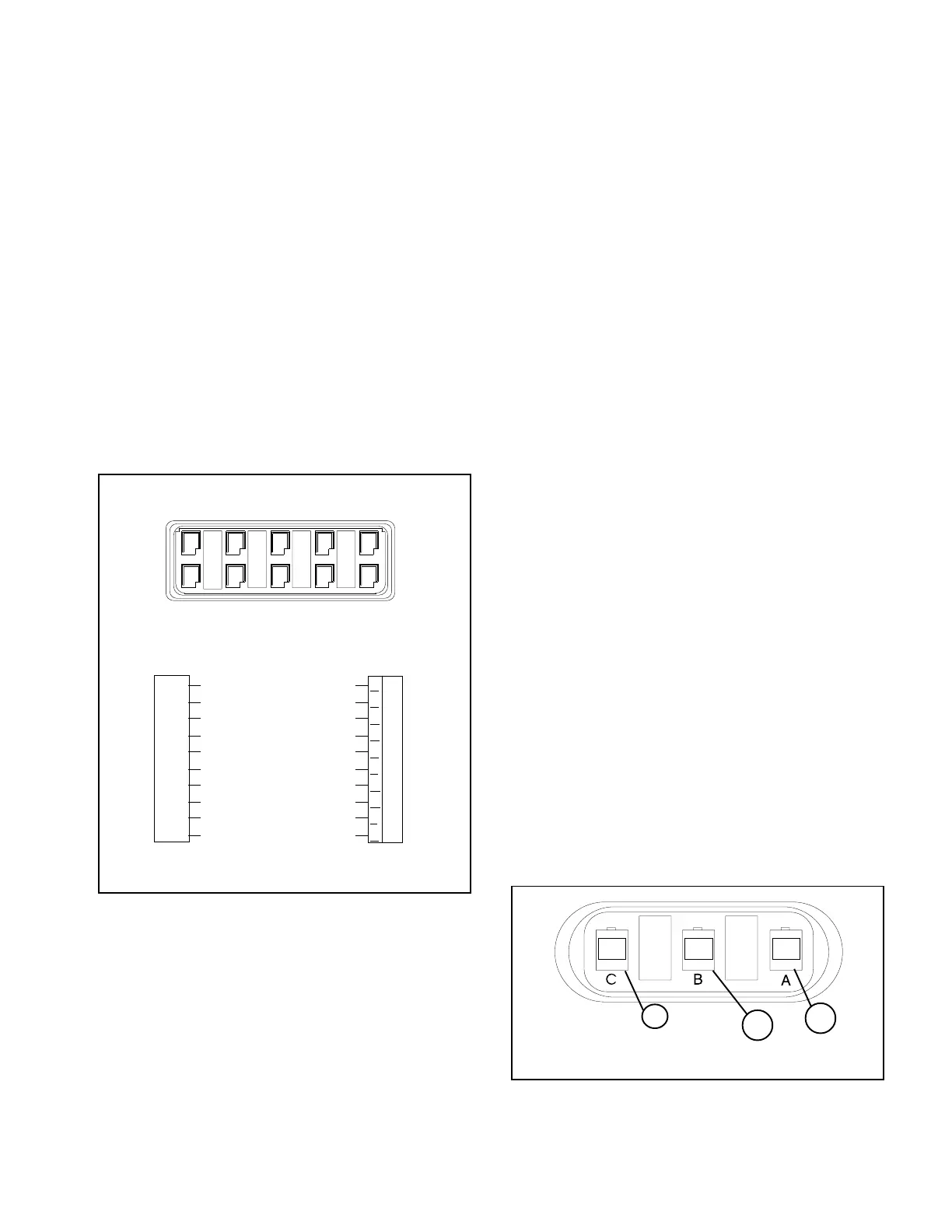

MAGNETIC HALL EFFECT SPEED AND

FLOW SENSORS:

Caution: Improper connection or voltage could

damage the Hall-effect sensor.

SPEED SENSOR:

Remove sensor from transaxle. Ground pin C

and connect clean 12 volts to pin A of the Speed

Sensor connector. Connect the positive lead

(red) of an ohmmeter or continuity tester to pin

B, and the negative lead (black) of the ohmmeter

or continuity tester to pin C, of the Speed Sensor

connector.

Holding the tip for sensor in open air should

result in a very high resistance (infinite), while

holding the tip of the sensor to within 1/16" of

steel material should result in a very low resistance

(near zero).

SPEED INPUT:

Turn rotary dial to SPEED position and

disconnect speed sensor from the main harness.

Using a clip lead or other jumper wire (such as a

paper clip bent in a U), several times rapidly

short together pins B and C of the 3-pin

connector (See FIG. 2). The monitor should

respond with some speed reading.

FLOWMETER:

The Flowmeter has an indicating light on the top

for diagnostics. As fluid flows through the meter,

or if the Rotor is spun by hand, the light should

flash with a frequency proportional to the speed

of the Rotor. No light at all indicates no power to

the meter. A steady light indicates a faulty meter.

FLOW INPUT:

Turn rotary dial to TOTAL VOLUME (not APP.

RATE), turn Master ON/OFF Switch to ON, and

turn all Boom sections ON. Disconnect flow

sensor from the main harness. Using a clip lead

or other jumper wire (paper clip bent in a U),

several times rapidly short together pins B and C

of the 3-pin connector. (See FIG. 2) The monitor

should respond with some flow reading.

1. Pin A- 12V Pos. 2. Pin B- Signal

3. Pin C- 12V Neg.

SPEED SENSOR AND FLOWMETER POWER:

The Speed Sensor and Flowmeter both have a

12 volt power supply. Check for 12 volts between

pins A and C in the connector at the sensors. If

power is not present, make sure the sensor power

wire is not open or shorted to ground or to

another wire. If this wire has a problem, the

monitor may exhibit erratic behavior or not

function at all.

SPRAY PRO

- TROUBLESHOOTING

FIG. 1

1. Pinout Locations

1797-1250

CHECKING INDIVIDUAL COMPONENTS:

MONITOR:

The only way to field test a monitor is to connect

it to a harness on a vehicle with a known working

console.

HARNESS:

The harness can be checked using an ohmmeter

or continuity tester. The wiring diagram below

(See FIG. 1) shows the pin out of all connectors.

Simply check for continuity between connected

pins and for no continuity between unconnected

pins.

POWER:

The Spray Pro cable has a ten-pin connector

labeled A-K. (See FIG. 1) Check between J-K

with a voltmeter or test light. If there is no power,

trace cable toward battery looking for breaks. Also

check fuses that supply power to the monitor.

1798

1

2

3

3-Pin Connector

A

B

C

D

E

F

G

H

J

K

E

D

CBA

F

GHJK

Monitor

Connection

Run/Hold Signal - Brown

Option Control - Red

Speed Power - Orange

Speed Signal - Yellow

Speed Ground - Green

Flow Power - Blue

Flow Signal - Violet

Flow Ground - Gray

Battery Ground - White

Battery Power - Black

SPRAY PRO

™

Monitor

10-Pin Metri-Pack Tower

Main Wiring Harness Ten Pin Connector

Loading...

Loading...