Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

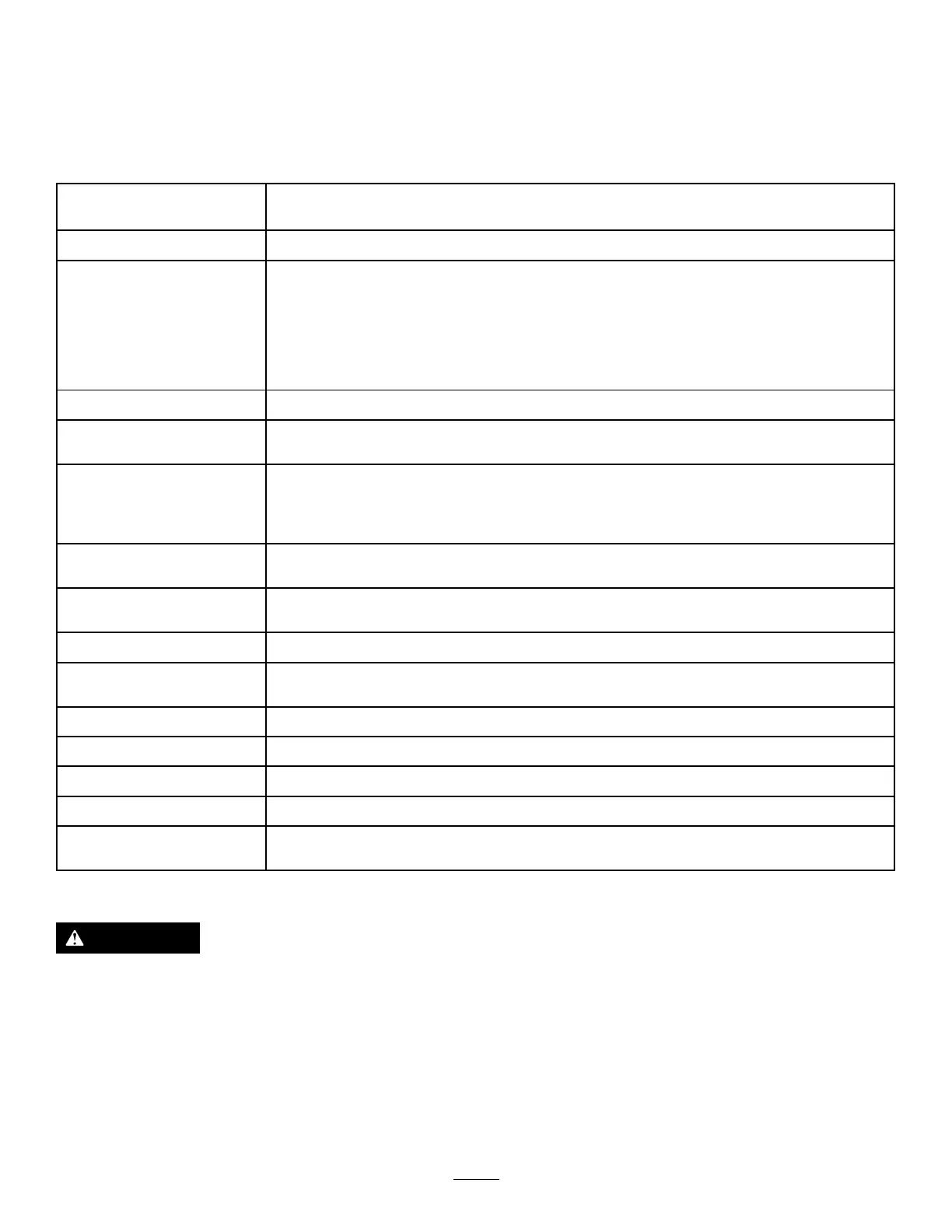

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst50hours

•Checkandadjustthetracktension.

Beforeeachuseordaily

•Greasethemachine.(Greaseitimmediatelyaftereverywashing.)

•Checktheengine-oillevel.

•Checktheconditionofandcleanthetracks.

•Cleantheenginescreen.

•Checktheconditionoftheteeth;rotateorreplaceanythatarewornordamaged

andtorquethenutsforallteeth.

•Checkforloosefasteners.

Aftereachuse

•Removedebrisfromthemachine.

Every25hours

•Checkthebatteryelectrolytelevel.

•Checkthehydraulic-uidlevel.

Every100hours

•Changetheengineoilandoillter(moreoftenindirtyordustyconditions).

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

Every150hours

•Inspecttheprimarylter.

•Replacethelow-pressurefuellter(moreoftenindirtyordustyconditions).

Every200hours

•Changetheengine-oillter.

•Replacethehydrauliclter.

Every250hours

•Checkandgreasetheroadwheels.

Every300hours

•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checktheinnerairlter.

Every400hours

•Changethehydraulicuid.

Every500hours

•Replaceandgapthesparkplug(s).

Every600hours

•Replacetheinnerairlter.

Every1,500hours

•Replaceallmovinghydraulichoses.

Yearlyorbeforestorage

•Checkandadjustthetracktension.

•Touchupchippedpaint.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

20

Loading...

Loading...