– 61 –

Check code

Location

of

detection

Description System status

Check code detection

condition(s)

Check items (locations)

• Check outdoor unit model.

(Check whether the

outdoor unit corresponds

to Air to Air Heat

Exchanger type or not.)

Outdoor units

model

disagreement

trouble

Indoor unit Stop of

corresponding

unit

In case of different outdoor

unit (Not corresponded to

Air to Air Heat Exchanger

type)

L02 L02 —

• Check indoor addresses.

• Check for any change

made to remote controller

connection (group/

individual) since indoor

address setting.

Duplicated

indoor header

unit

Indoor unit Stop of

corresponding

unit

There are more than one

header units in group.

L03 — —

• Check power supply

voltage. (AC380V ± 10%).

• Check for failure in

compressor.

• Check for possible cause

of abnormal overloading.

• Check for failure in outdoor

P.C. board (compressor).

Compressor

trouble

(out of sync)

Compressor

P.C. board

1∗: Compressor

1 side

2∗: Compressor

2 side

All stop Judged that the

synchronization could not be

taken.

H17 H17

• Check line addresses.Duplicated

outdoor line

address

I/F All stop There is duplication in line

address setting for outdoor

units belonging to different

refrigerant piping systems.

L04 L04 —

Main

remote

controller

Outdoor 7-segment display

Check

code

Sub-code

• Check for disconnection of

TK1 sensor.

• Check resistance

characteristics of TK1

sensor.

• Check for connection

trouble involving TK1 and

TK2 sensors

• Check for clogging in oil

equalizing circuit capillary.

• Check for refrigerant

entrapment inside

compressor.

Oil level

detection

circuit trouble

I/F01: TK1 oil

circuit trouble

02: TK2 oil

circuit trouble

All stop No temperature change is

detected by TK1 despite

compressor 1 having been

started.

H16 H16

• Check for disconnection of

TK2 sensor.

• Check resistance

characteristics of TK2

sensor.

• Check for connection

trouble involving TK1 and

TK2 sensors

• Check SV3F valve

malfunction.

• Check for clogging in oil

equalizing circuit capillary.

• Check for refrigerant

entrapment inside

compressor.

No temperature change is

detected by TK2 despite

compressor 2 having been

started.

• Check connection of TK1

sensor connector.

• Check resistance

characteristics of TK1

sensor.

• Check for failure in outdoor

P.C. board (I/F).

Trouble in

temperature

sensor for oil

level detection

I/F01: TK1 sensor

trouble

02: TK2 sensor

trouble

All stop Sensor resistance is infinity

or zero (open/short circuit).

H08 H08

• Check installation of TD2

sensor.

• Check connection of TD2

sensor connector and

wiring.

• Check resistance

characteristics of TD2

sensor.

• Check for failure in outdoor

P.C. board (I/F).

TD2 sensor

miswiring

(incomplete

insertion)

I/F All stop Discharge temperature of

(TD2) does not increase

despite compressor 2 being

in operation.

H15 H15 —

• Check connection of TK2

sensor connector.

• Check resistance

characteristics of TK2

sensor.

• Check for failure in outdoor

P.C. board (I/F).

All stop Sensor resistance is infinity

or zero (open/short circuit).

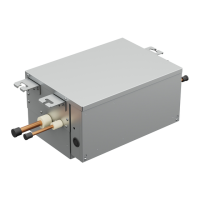

Indoor unit (including Hot Water Module)

Loading...

Loading...