– 64 –

Check code

Location

of

detection

Description System status

Check code detection

condition(s)

Check items (locations)

Main

remote

controller

Outdoor 7-segment display

Check

code

Sub-code

• Check float switch

connector.

• Check operation of drain

pump.

• Check drain pump circuit.

• Check drain pipe for

clogging.

• Check for failure in indoor

P.C. board.

Indoor overflow

trouble

Indoor unitDetected indoor

address

All stop • Float switch operates.

• Float switch circuit is

open-circuited or

disconnected at connector.

P10 P10

• Check shortage of

refrigerant.

• Check connection of TE1,

TE2 and TE3 sensors.

• Check resistance

characteristics of TE1,

TE2, and TE3 sensors.

• Check disconnection of

TS1 sensor.

• Check resistance

characteristics of TS1

sensor.

• Check outdoor I/F P.C.

board malfunction.

• Check operation of 4 way

valve.

• Check operation of outdoor

PMV (1, 2, 3).

• Check short circuit from

outlet air to inlet air.

Outdoor heat

exchanger

freeze trouble

I/F All stop • Outdoor heat exchanger

remaining frost detection

has occurred eight times

or more due to abnormal

frost formation in heating

operation.

P11 — —

• Check connection of fan

connector and wiring.

• Check for failure in fan

motor.

• Check for failure in indoor

P.C. board.

• Check impact of outside air

treatment (OA).

Indoor fan

motor trouble

Indoor unit Stop of

corresponding

unit

• Motor speed

measurements

continuously

deviate from target

value.

• Overcurrent

protection is

activated.

P12 — —

• Check outdoor fan system

trouble.

• Check IPM and heat sink for

thermal performance for

trouble installation.

(e.g. mounting screws and

thermal conductivity)

• Check for failure in

Compressor P.C. board.

(trouble IPM built-in

temperature sensor (TH))

Heat sink

overheating

trouble

Compressor

P.C. board

1∗: Compressor

1 side

2∗: Compressor

2 side

All stop Temperature sensor built

into IPM (TH) is overheated.

P07 P07

• Check outdoor fan system

trouble.

• Check IPM and heat sink

for thermal performance for

troubled installation.

(e. g. mounting screws and

thermal conductivity)

• Check for failure in

compressor P.C. board.

(failure IPM built-in

temperature sensor (TH))

•

Check shortage of refrigerant.

• Check outdoor service

valves.

• Check connection of TL2

sensor.

• Check resistance

characteristics of TL2 sensor.

• Check resistance

characteristics of TO sensor.

• Check malfunctions of Pd

and Ps sensors.

• Check outdoor I/F P.C.

board malfunction.

• Check PMV2 and PMV3

Heat sink

overheating

trouble

Heat sink dew

condensation

trouble

01: Compressor

1 heat sink

trouble

02: Compressor

2 heat sink

trouble

04: Heat sink

dew

condensation

I/F All stop Condensation detection on

heat sink has occurred four

times or more in operation.

Temperature sensor built

into IPM (TH) is overheated.

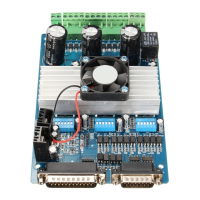

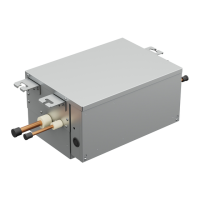

Indoor unit (including Hot Water Module)

Loading...

Loading...