SERVICE MANUAL

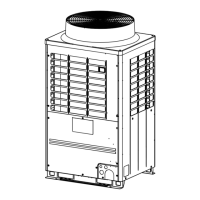

AIR-CONDITIONER (MULTI TYPE)

<SUPER MODULAR MULTI SYSTEM - i>

Outdoor Unit

Model name:

FILE NO. SVM-13024-2

MMY-MAP0804HT8(J)P

MMY-MAP1004HT8(J)P

MMY-MAP1204HT8(J)P

MMY-MAP1404HT8(J)P

MMY-MAP1604HT8(J)P

MMY-MAP0804HT8(J)P-E

MMY-MAP1004HT8(J)P-E

MMY-MAP1204HT8(J)P-E

MMY-MAP1404HT8(J)P-E

MMY-MAP1604HT8(J)P-E

MMY-MAP0804HT8(J)P-TR

MMY-MAP1004HT8(J)P-TR

MMY-MAP1204HT8(J)P-TR

MMY-MAP1404HT8(J)P-TR

MMY-MAP1604HT8(J)P-TR

<Heat Pump Model>

<4-way Cassette Type>

(MMU-AP***4HP-E) (Made in Thailand model) SVM-13-011

<2-way Cassette Type>

(MMU-AP

***

2WH) A10-007

<Concealed Duct Standard Type>

(MMD-AP

***

6BH-E) A12-005

<Slim Duct Type>

(MMD-AP0244SPH-E, AP0274SPH-E) A12-005

Fresh Air Intake Indoor Unit Type

(MMD-AP

****

HFE) A06-016

<Air to Air Heat Exchanger with DX Coil Unit Type>

(MMD-VN

*****

HEXE

*

) A10-022-2

High-wall Type

(MMK-AP

***

3H) (Made in Thailand model) SVM-09-059

Console Type

(MML-AP

****

NH-E) (Made in Thailand model) SVM-11-036

Other indoor units

(MM

*

-AP

*****

H

*

) A10-033

MMY-MAP0804HT7(J)P

MMY-MAP1004HT7(J)P

MMY-MAP1204HT7(J)P

MMY-MAP1404HT7(J)P

MMY-MAP1604HT7(J)P

MMY-MAP0804T8(J)P

MMY-MAP1004T8(J)P

MMY-MAP1204T8(J)P

MMY-MAP1404T8(J)P

MMY-MAP1604T8(J)P

MMY-MAP0804T8(J)P-T

MMY-MAP1004T8(J)P-T

MMY-MAP1204T8(J)P-T

MMY-MAP1404T8(J)P-T

MMY-MAP1604T8(J)P-T

MMY-MAP0804T8(J)P-SG

MMY-MAP1004T8(J)P-SG

MMY-MAP1204T8(J)P-SG

MMY-MAP1404T8(J)P-SG

MMY-MAP1604T8(J)P-SG

<Cooling Only Model>

MMY-MAP0804T8(J)P-ID

MMY-MAP1004T8(J)P-ID

MMY-MAP1204T8(J)P-ID

MMY-MAP1404T8(J)P-ID

MMY-MAP1604T8(J)P-ID

This service manual provides relevant explanations about new outdoor unit (SMMS-i).

Please refer to the following service manuals for each indoor units.