NOTE :

Gas leak check position

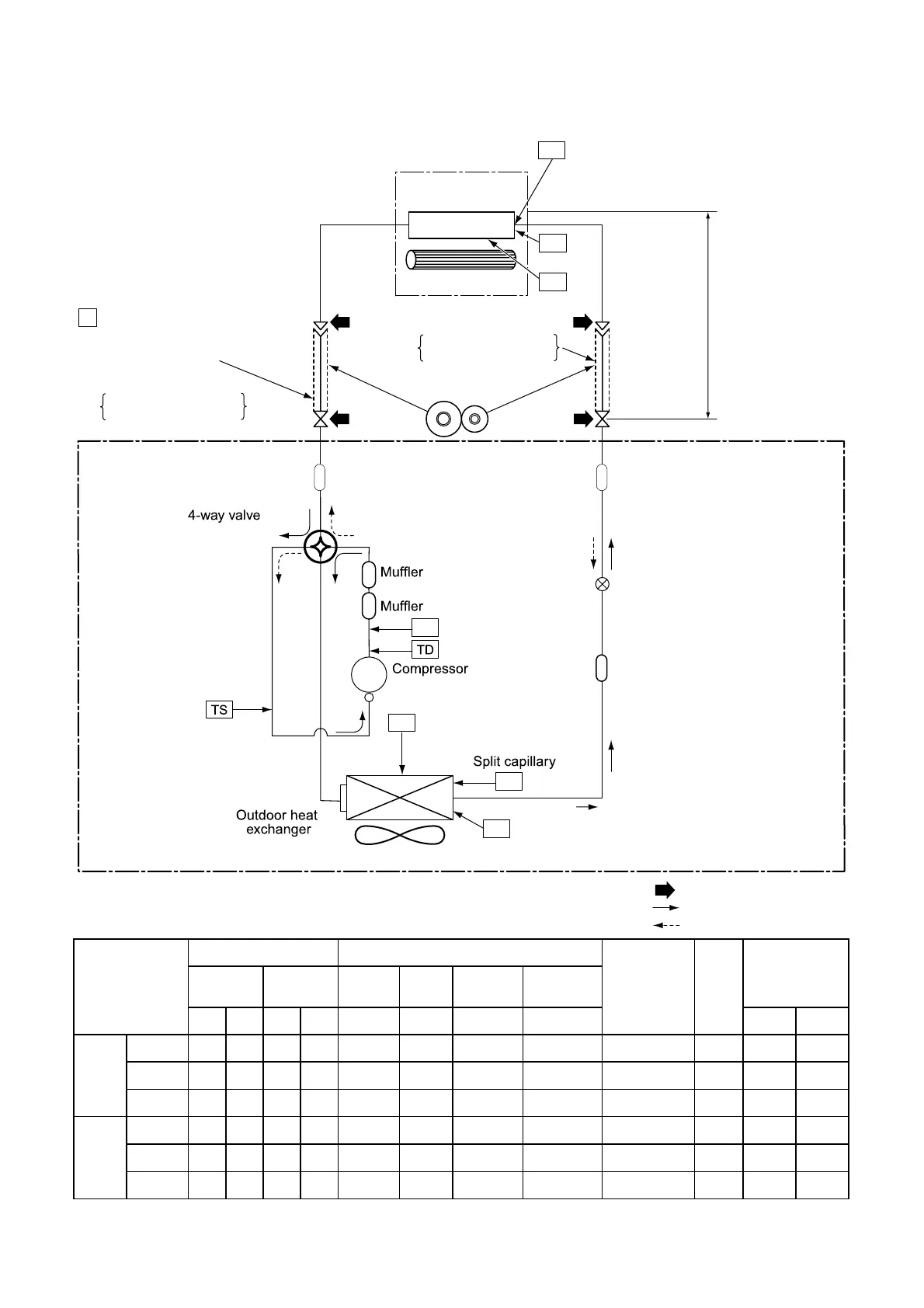

Refrigerant flow (Cooling)

Refrigerant flow (Heating)

INDOOR UNIT

TCJ

Indoor heat

exchanger

Cross flow fan

Deoxidized copper pipe

Outer dia. : 9.52mm

Thickness : 0.8mm

Sectional shape

of heat insulator

Allowable height

difference : 15m

Allowable pipe length

P

Pressure measurement

Gauge attaching port

Vacuum pump connecting port

Deoxidized copper pipe

Outer dia. : 15.88mm

Thickness : 0.8mm

Pulse Modulating

valve at liquid side

OUTDOOR UNIT

TC

TA

Strainer

Strainer

Refrigerant amount : 1.90kg

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

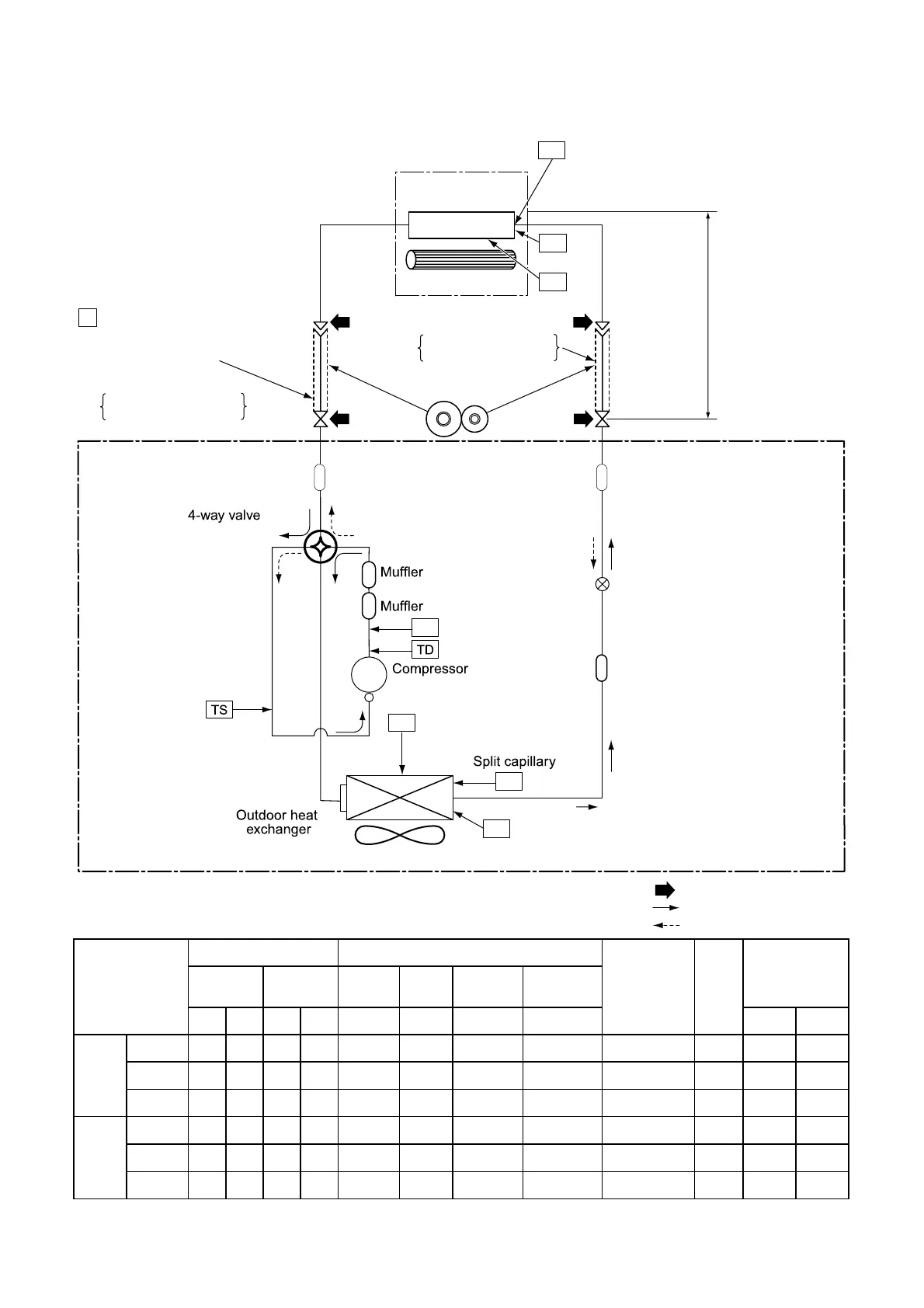

Pressure Pipe surface temperature (°C)

Compressor

drive

revolution

frequency

(rps)

Indoor

fan

Indoor/Outdoor

temp.conditions

(DB/WB) (°C)

(MPa)

(kg/cm2)

Discharge Suction

Indoor heat

exchanger

Outdoor heat

exchanger

Pd Ps Pd Ps (TD) (TS) (TC) (TE)

Indoor Outdoor

Cooling

Standard

3.14 0.96 32.0 9.8 84 13 12 37 72

HIGH 27/19 35/–

Overload

3.52 1.28 35.9 9.8 74 25 31 54 40

HIGH

32/24

46/–

Low load

2.12 0.78 21.6 8.0 60 5 4 0 54

LOW

18/15.5 -15/–

* 4 poles are provided to this compressor.

The compressor frequency (Hz) measured with a clamp meter is 2 times of revolutions (rps) of the compressor.

Heating

Standard

2.30 0.63 23.5 6.4 70 0 40 1 81

HIGH

20/- 7/6

Overload

3.31 0.98 33.7 10.0 68 13 48 14 57

HIGH

28/- 24/18

Low load

1.42 0.32 14.5 3.3 30 20 23 -17 90

LOW

0/- -15/–

Max. : 30m

Min. : 5m

High Pressure switch

NA220A1F-20

N

TO

TE

Propeller fan

TL

Strainer

Loading...

Loading...