6-5. Brazing of Pipes

6-5-1. Materials for Brazing

1. Silver brazing filler

Silver brazing filler is an alloy mainly composed

of silver and copper.

It is used to join iron, copper or copper alloy, and

is relatively expensive though it excels in

solderability.

2. Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used

to join copper or copper alloy.

3. Low temperature brazing filler

Low temperature brazing filler is generally called

solder, and is an alloy of tin and lead.

Since it is weak in adhesive strength, do not use

it for refrigerant pipes.

1) Phosphor bronze brazing filler tends to react

with sulfur and produce a fragile compound

water solution, which may cause a gas leakage.

Therefore, use any other type of brazing filler

at a hot spring resort, etc., and coat the surface

with a paint.

2) When performing brazing again at time of

servicing, use the same type of brazing filler.

6-5-2. Flux

1. Reason why flux is necessary

• By removing the oxide film and any foreign

matter on the metal surface, it assists the flow

of brazing filler.

• In the brazing process, it prevents the metal

surface from being oxidized.

• By reducing the brazing filler's surface tension,

the brazing filler adheres better to the treated

metal.

2. Characteristics required for flux

• Activated temperature of flux coincides with the

brazing temperature.

• Due to a wide effective temperature range, flux

is hard to carbonize.

•

It is easy to remove slag after brazing.

• The corrosive action to the treated metal and

brazing filler is minimum.

• It excels in coating performance and is

harmless to the human body.

As the flux works in a complicated manner as

described above, it is necessary to select an

adequate type of flux according to the type and

shape of treated metal, type of brazing filler and

brazing method, etc.

3. Types of flux

• Noncorrosive flux

Generally, it is a compound of borax and boric

acid.

It is effective in case where the brazing

temperature is higher than 800°C.

• Activated

flux

Most of fluxes generally used for silver brazing

are this type.

It features an increased oxide film removing

capability due to the addition of compounds

such as potassium fluoride, potassium chloride

and sodium fluoride to the borax-boric acid

compound.

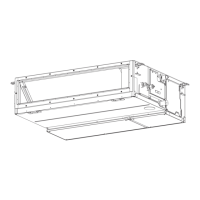

4. Piping materials for brazing and used

brazing filler/flux

Piping

material

Used brazing

filler

Used

flux

Copper - Copper Phosphor copper Do not use

Copper - Iron Silver Paste flux

Iron - Iron Silver Vapor flux

1)

2)

Do not enter flux into the refrigeration cycle.

When chlorine contained in the flux remains

within the pipe, the lubricating oil deteriorates.

Therefore, use a flux which does not contain

chlorine.

3) When adding water to the flux, use water which

does not contain chlorine

(e.g. distilled water or ion-exchange water).

4) Remove the flux after brazing.

Loading...

Loading...