20/32

2. Daily maintenance check

A daily maintenance check of the pallet truck can limit wear to a minimum:

• Check the wheels and axles for blockages. Remove the blockages if possible.

• Check the wheels for wear, cracks, flat spots or broken bearings. If you find anything,

replace the wheels. See chapter10.4 How to replace the wheels.

• Check if there are any damaged or loose bolts, nuts or cotter pins. Fasten them if

necessary.

• Check for oil leaks.

• Check if the lifting and lowering functions work properly.

• Ensure that the instruction manual is complete, legible and available for reference.

• Ensure that all decals are legible and in place.

• Check the entire machine for damage, corrosion or cracks in structural components.

A damaged or malfunctioning machine must never be used. If damage or

malfunctions are discovered during daily inspection or function tests, the machine

must be tagged and removed from service.

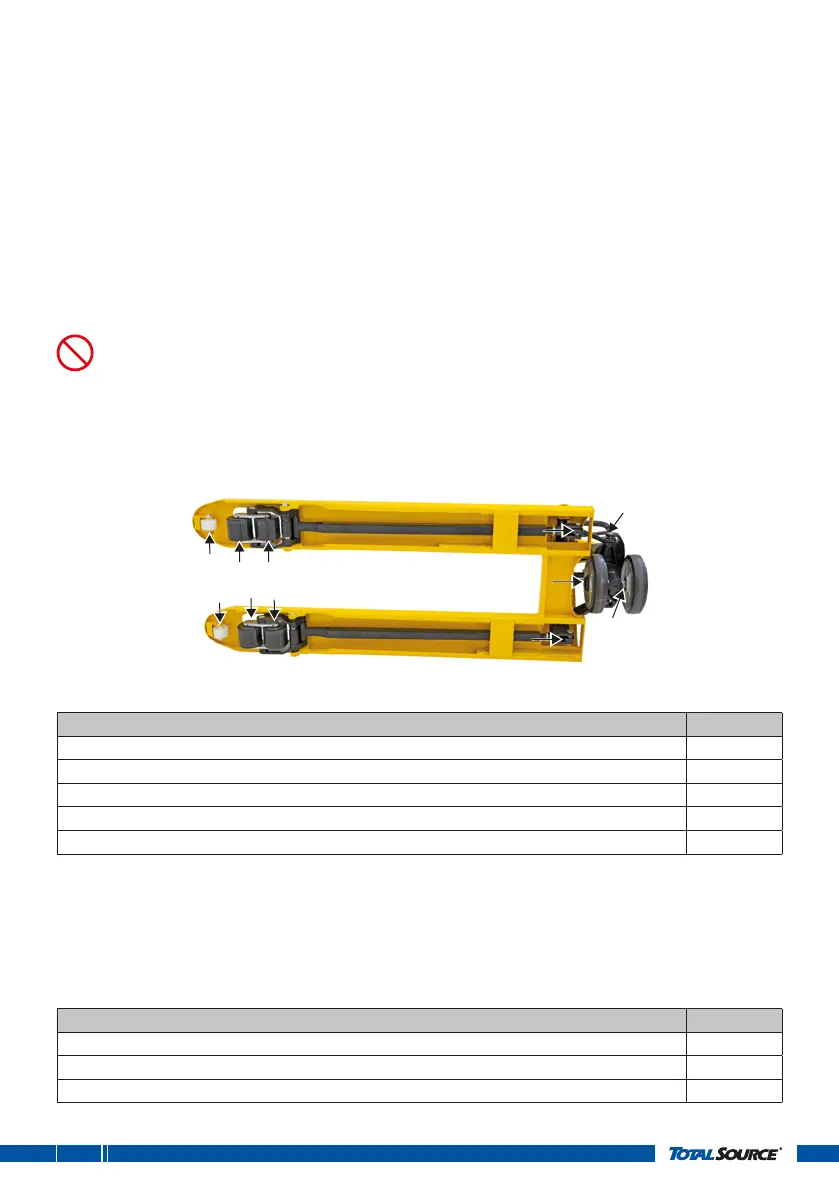

3. Lubrication

Use engine oil or grease to lubricate all moving parts.

Oil and grease Reference

Lubricating grease 107TA8448

Food grease 143TA6908

Multipurpose grease 165TA3769

Grease for food industry 152TA1875

Penetrating oil 144TA9266

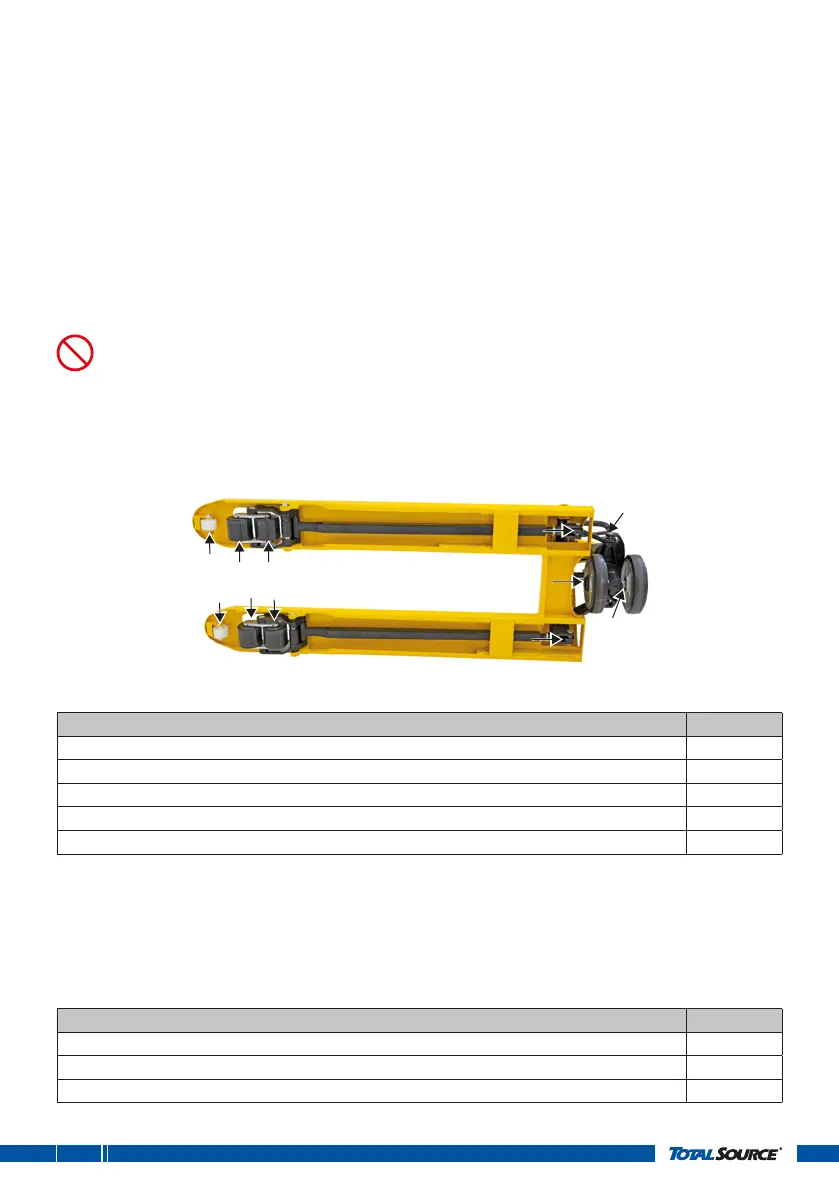

4. Check oil level

Please check the oil level every six months. The oil capacity is about 0.3 l. Top up the fluid

level in the rubber reservoir to 5 mm below the top; this must be done with the forks in

the lowered position. Use the correct type of hydraulic oil according to the temperature

conditions below.

Type oil Reference

Hydraulic oil ISO VG32 141TA2734

Hydraulic oil ISO VG32 for extremely cold temperatures 165TA7512

Hydraulic oil SH32 for food industry 165TA7513

Loading...

Loading...