22/32

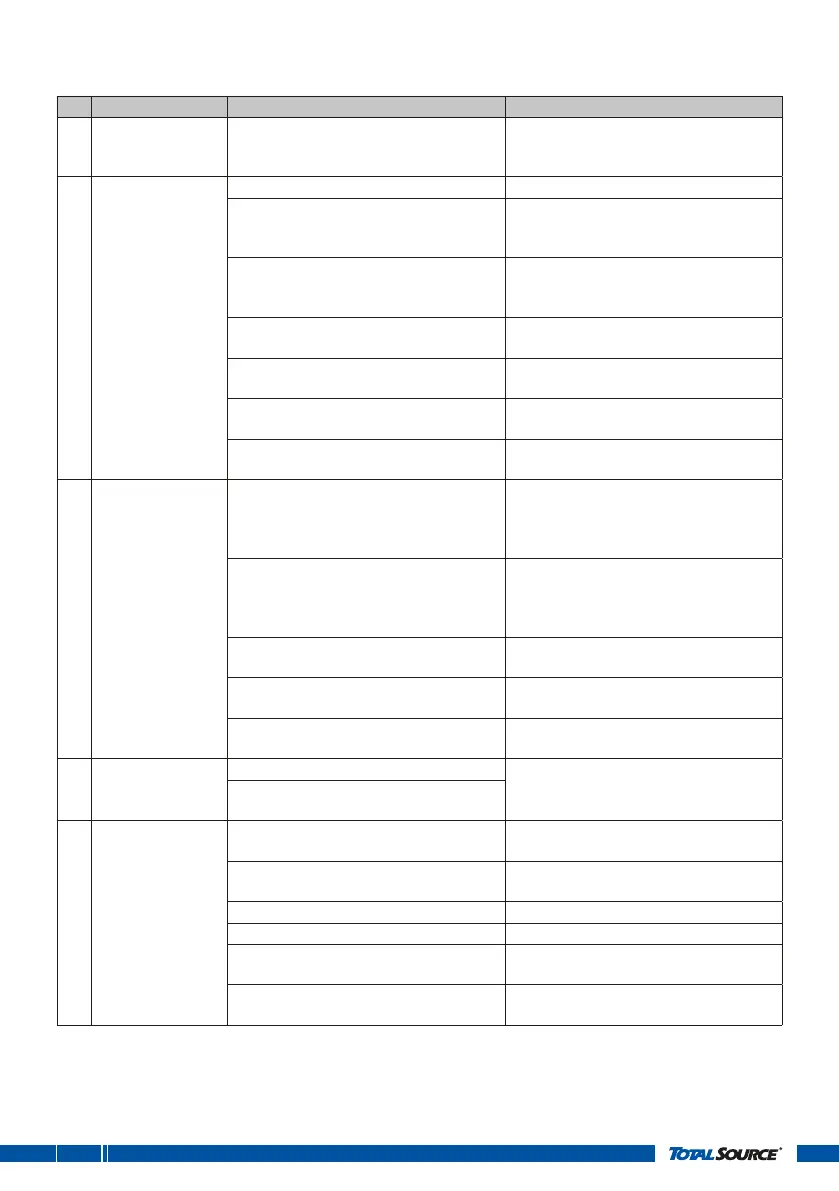

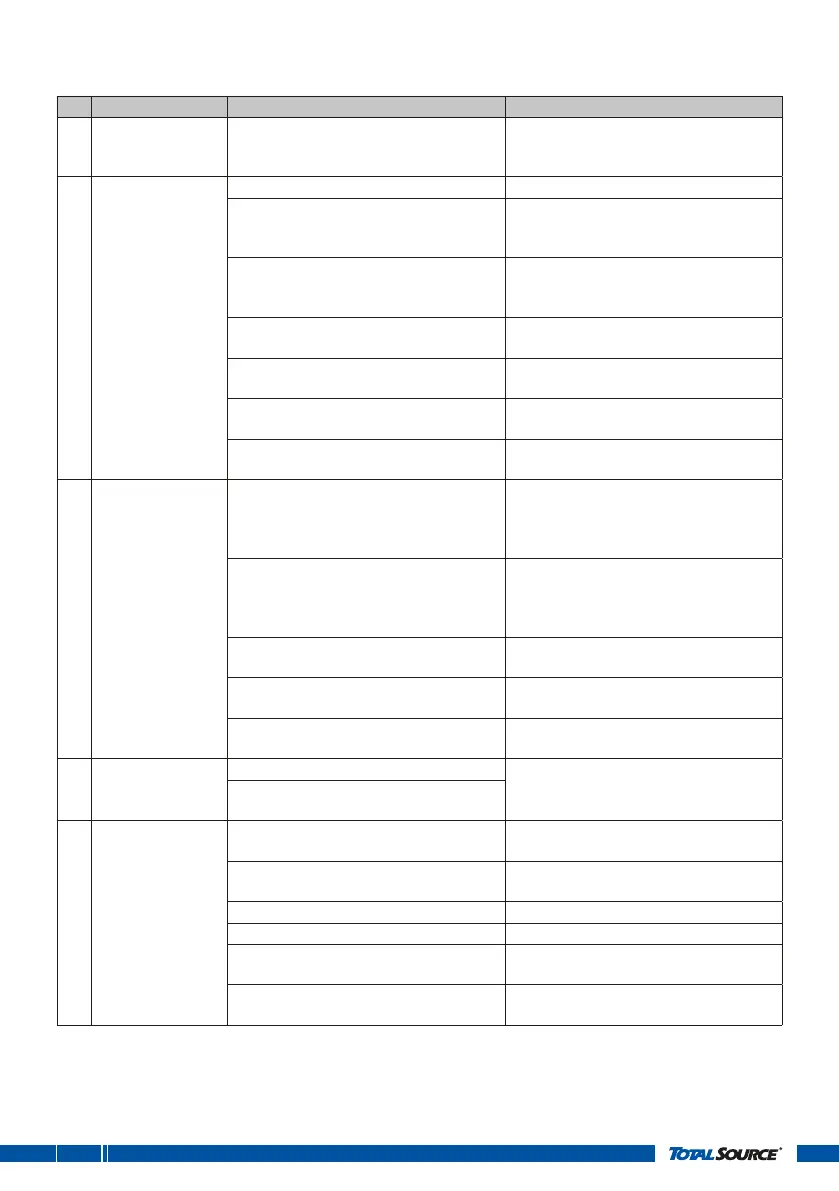

8. TROUBLESHOOTING

N° Problem Cause Action

1 The forks can’t be

raised up to the

maximum height

The level of hydraulic oil is too low Add hydraulic oil, see chapter7

2 The forks can’t be

raised

The level of hydraulic oil is too low Add hydraulic oil, see chapter7

The oil contains impurities

(forexample water, sand, dust,

rust…)

Change the oil, see chapter7

The nut or screw were tightened too

much, causing the pumping valve to

stay open

Adjust the nut or screw

Air enters the hydraulic oil Bleed the air, see procedure in

chapter7

Control lever is no longer adjusted

correctly

Follow the procedure for adjusting the

control lever in chapter7

Load is too heavy, pressure relief

valve is activated

Reduce load

Temperature is too low and the

hydraulic oil has become too thick

Move truck to a warmer location and

check intended use

3 The forks can’t be

lowered

The piston rod or pump body is

deformed due to partial loading

slanting to one side or due to

overloading

Replace the piston rod or pump body

The forks were kept in their highest

position for a long time with the piston

rod exposed, resulting in rust and

causing the rod to jam

Lubricate the rod. Keep the forks

in the lowest position when not in

use, and pay more attention to the

lubrication of the rod.

The adjusting nut or screw is not in

the correct position

Adjust the nut or the screw

Control lever is no longer adjusted

correctly

Follow the procedure for adjusting the

control lever in chapter6

Obstacle located under truck, in fork

mechanism…

Remove the obstacle with caution

4 Leaks Sealing parts are worn or damaged Replace the parts, see spare parts list

Some parts are cracked or slightly

worn

5 The forks

descend without

the release valve

being operated

The impurities in the oil prevent the

release valve from closing properly

Change the oil, see chapter7

Some parts of the hydraulic system

are cracked or worn

Inspect and replace the worn parts,

see spare parts list

Air enters the hydraulic oil Bleed the air, see procedure chapter7

Sealing parts are worn or damaged Replace the seals, see spare parts list

The adjusting nut or screw is not in

the correct position

Adjust the nut or the screw

Control lever is no longer adjusted

correctly

Follow the procedure for adjusting the

control lever in chapter6

If none of these troubleshooting suggestions or solutions were helpful, please contact your

local dealer or the manufacturer.

Loading...

Loading...