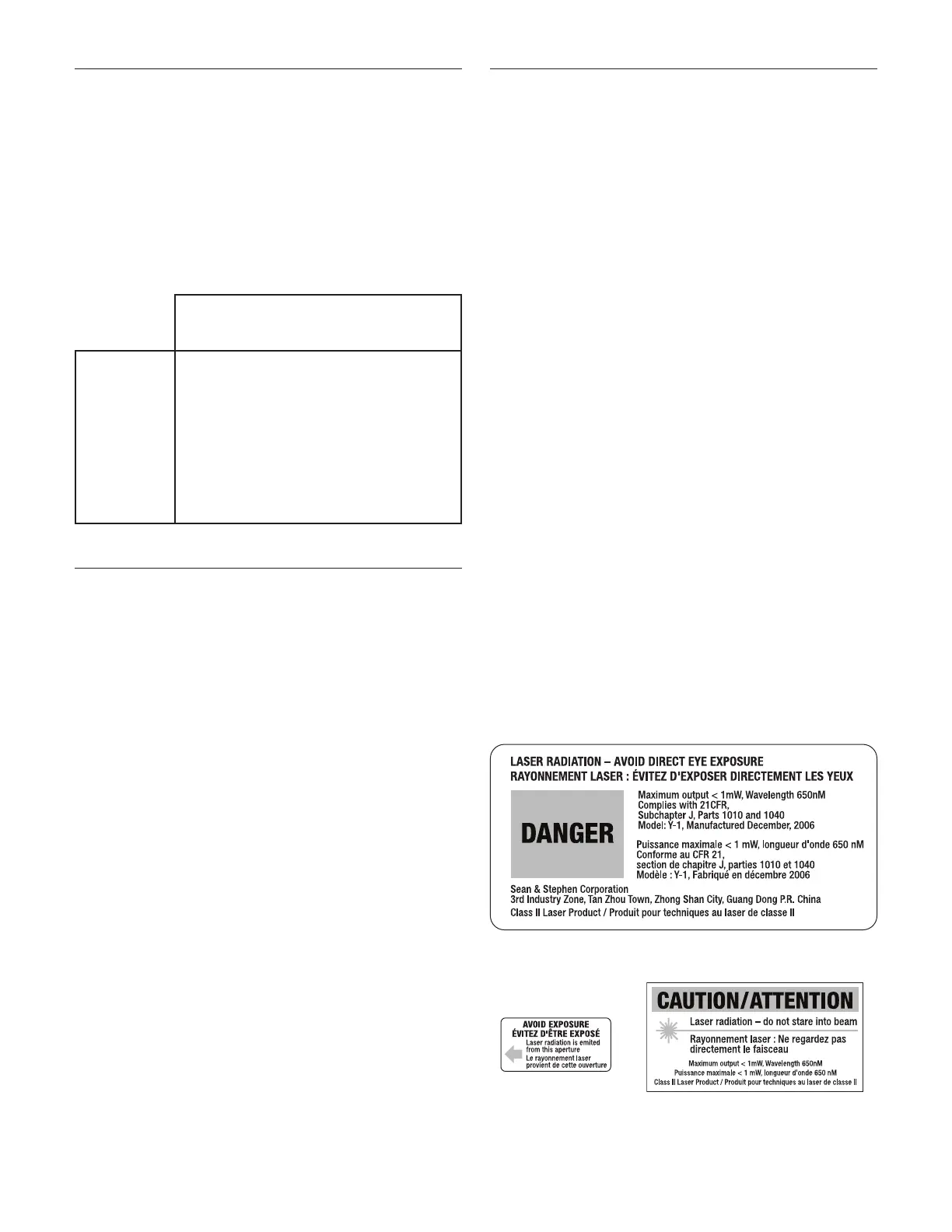

Total Extension Cord Length (in feet)

Table A

25 50 100 150 200

AMP Rating Wire Gauge

0–10 18 14 12 10 8

10–12 16 14 10 8 8

12–14 14 12 10 8 6

14–16 14 12 10 8 6

16–18 12 12 8 8 6

Extension Cords:

Make sure your extension cord is not damaged. When

using an extension cord, be sure to use one heavy

enough to carry the current your product draws.

For lengths more than100 ft, No. 10 AWG extension

cords should be used. An undersized cord results in a

drop in line voltage and loss of power and overheating.

(NOTE: Table A below shows the correct size to use

depending on cord length and nameplate ampere

rating. When in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.)

Using the Laser collimator system

WARNING: Do not stare directly at the laser beam.

Never aim the beam at any person or an object other

than the work piece.

Do not deliberately aim the beam at personnel and

ensure that it is not directed towards the eye of a person

for longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy work

piece without reflective surfaces, i.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet steel or the like is not suitable for laser use as

the reflective surface could direct the beam back at the

operator.

Only turn the laser beam on when the tool is on the work

piece.

1. Mark the line of the cut on the work piece.

2. Adjust the depth of the cut and bevel angle as

required.

3. Rest the front edge of the base on the work piece.

4. Switch on the laser beam using the laser light on/off

button.

5. Align the beam with the line on the work piece.

6. Start the motor by squeezing the trigger switch.

7. Always let the blade reach full speed (approximately

2 seconds) before you begin to cut into the work

piece.

8. Slowly push the saw forward using both hands,

keeping the red laser light beam on the line of cut.

9. After completing your cut, release the trigger switch

and allow the blade to come to a complete stop. Do

not remove the saw from the work piece while the

blade is moving.

10. Switch off the laser beam on completion of the cut.

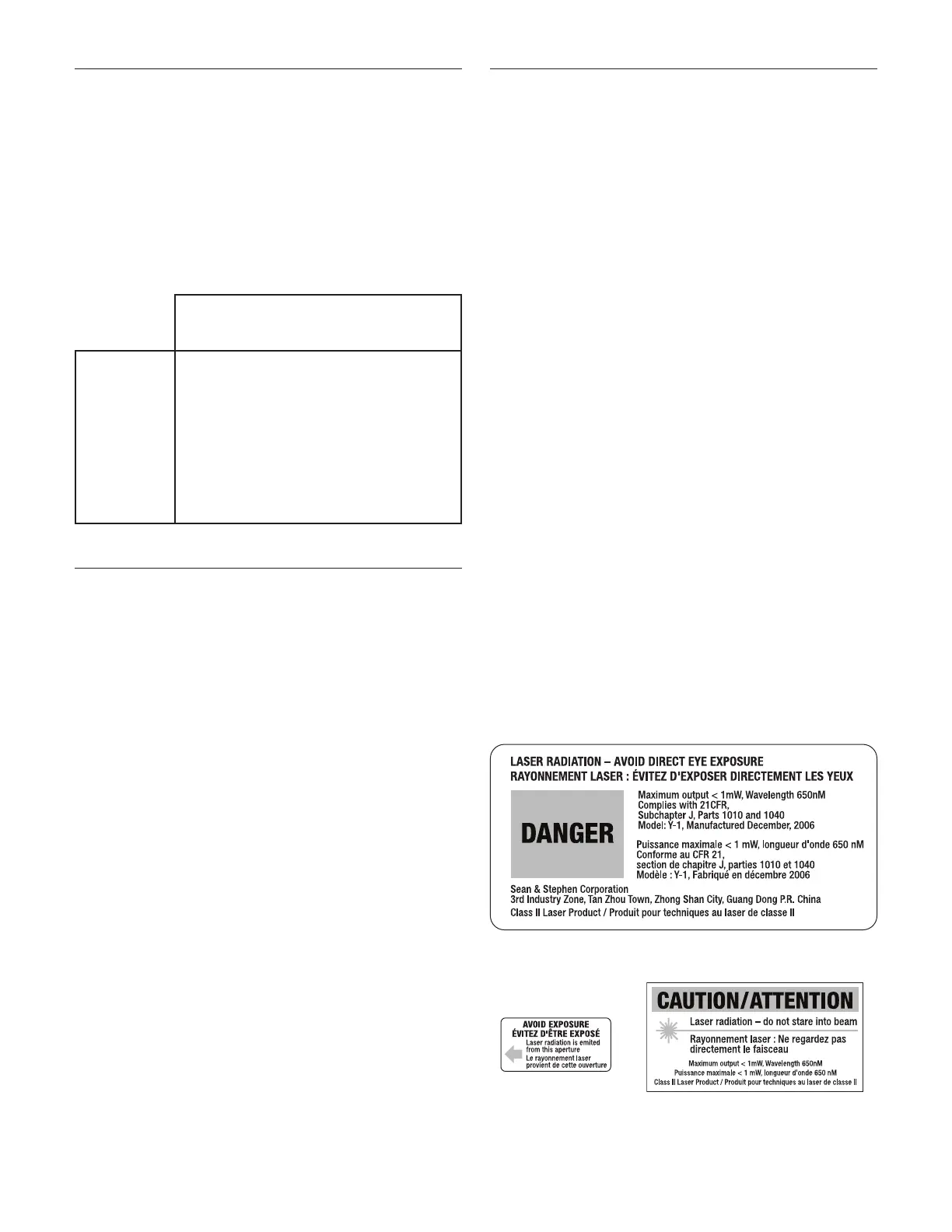

Safety rules for laser lights

The laser guide used in the tool is Class II with a

maximum output of 1 mW and a wavelength of 650 nm,

Complies with 21 CFR, Subchapter J, Parts 1010 and

1040, Class II laser product. The laser guide does not

normally present an optical hazard, although staring at

the beam may cause flash blindness.

User Information

CAUTION – The use of optical instruments with this laser

product will increase eye hazard.

CAUTION – The use of controls or adjustments or

performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• Do not stare into the laser beam.

• The laser shall be used and maintained in accordance

with the manufacturer’s instructions.

• Never aim the beam at any person or an object other

than the work piece.

• Do not disassemble the laser.

• Operate the laser only when cutting. Turn the laser off

after use.

Always ensure the laser beam is aimed at a sturdy work

piece without a reflective surface, i.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet or the like is not suitable for laser use as the

reflective surface could direct the beam back at the

operator.

This label is located on the top of the motor enclosure

(part # 63).

This label is located on the top

of the rocker arm (#87) beside

the laser battery box (#145) and

switch of laser (#139).

This label is located

on the lower back

edge of the safety

guard (#105)

Loading...

Loading...