of the bolts in the proper order.

24

9

9

9

20

20

2

2

23

2

3

3

3

4

4

22

6

6

6

7

7

7

8

8

10

10

10

19

19

18

18

17

17

21

16

16

16

15

15

15

14

14

14

13

13

13

12

12

11

11

16 bolt flange 20 bolt flange 24 bolt flange

Flanges with More than 24 Bolts

Sequentially tighten the first 12 bolts to a snug tight-

ness. Tighten the next 12 consecutively numbered bolts

in sequence, to the final torque. Then, apply final torque

to the first 12 bolts and the bolts not yet tightened (i.e.,

unnumbered bolts in the figure at right sure to start with

bolt “1” and move progressively around the flange in a

clockwise direction.

24

9

20

23

3

4

22

8

10

19

18

17

21

16

15

14

13

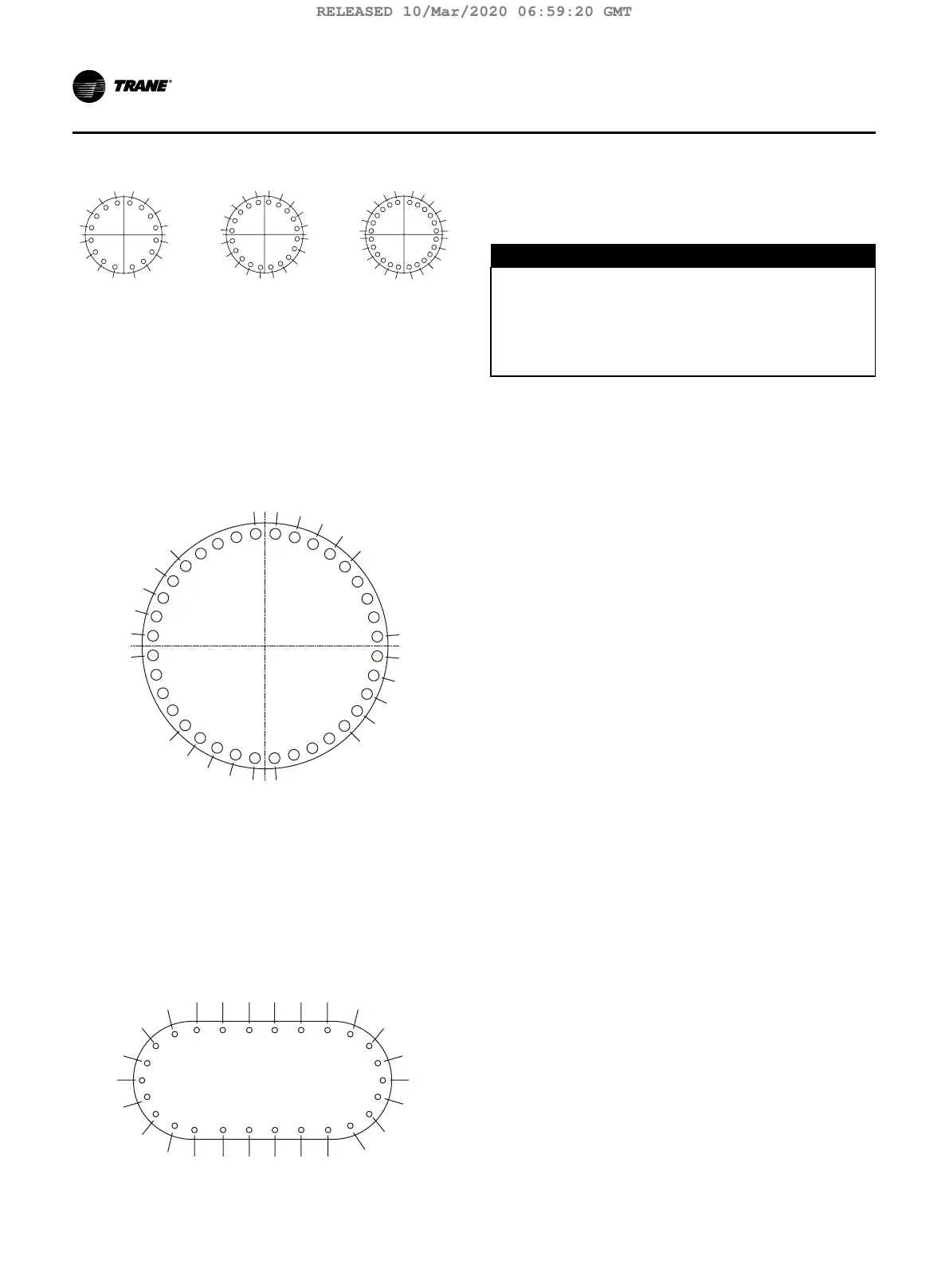

Evaporator Water Box Covers

Ensure that the water box head rests tightly against the

tube sheet; then snugly tighten the 26 bolts in sequential

order. If excessive tube sheet crown prevents the head

from contacting the tube sheet, tighten the bolts located

where the greatest gaps occur. Be sure to use an equal

number of bolt turns from side to side. Then, apply final

torque to each bolt in sequential order.

24

5

20

2

23

4

6

7

8

18

26

25

17

16

15

12

Pressure Testing Waterside Piping

Water side design pressure is either 150 or 300 psig refer

to unit nameplate or to submittal documentation.

D

NOTICE

Equipment Damage!

Do not over pressurize the system or exceed design

pressure. Always perform as a hydro pressure test

with water present in piping and water boxes. Fail-

ure to follow these recommendations could result in

equipment damage.

24 TCVHE-SVX04D-EN

Installation Water Piping

RELEASED 10/Mar/2020 06:59:20 GMT

Loading...

Loading...