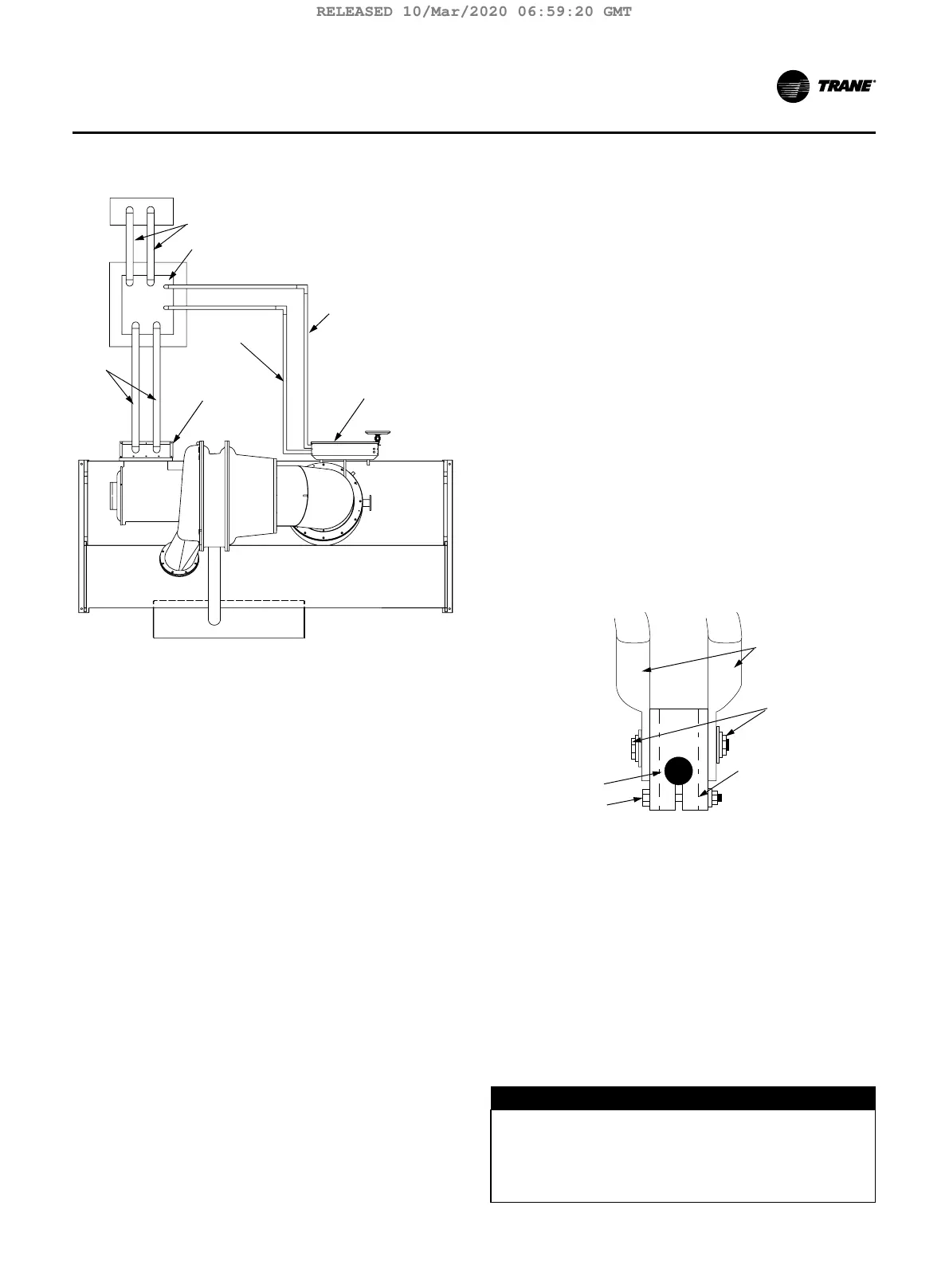

Figure 22. Typical equipment room layout for units with

remote-mounted starters

1

2

3

4

6

7

5

1. Line side power conduits

2. Remote-mounted starter

3. Unit control panel

4. IPC Circuit conduit less than 30V

Note: Must enter the low voltage Class 2 portion of the

unit control panel (1000 feet max).

5. Motor terminal box

6. 115 V Control conduit

Note: Must enter the higher than 30 Vdc Class 1 portion

of the until control panel.

7. Lead power wiring

Note: Refer to the unit field connection diagram for ap-

proximate unit control panel knock out locations.

Note: To prevent damage to the unit control panel com-

ponents, do not route control conduit into the top

of the box.

Starter to Motor Wiring (Re-

mote-Mounted Starters Only)

Ground Wire Terminal Lugs

Ground wire lugs are provided in the motor terminal box

and in the starter panel.

Terminal Clamps

Terminal clamps are supplied with the motor terminals

to accommodate either bus bars or standard motor

terminal wire lugs. Terminal clamps provide additional

surface area to minimize the possibility of improper elec-

trical connections.

Wire Terminal Lugs

Wire terminal lugs must be field supplied.

• Use field provided crimp type wire terminal lugs

properly sized for the application.

Note: Wire size ranges for the starter line and load-side

lugs are listed on the starter submittal drawings

supplied by the starter manufacturer or Trane.

Carefully review the submitted wire lug sizes for

compatibility with the conductor sizes specified

by the electrical engineer or contractor.

• A terminal clamp with a 3/8” bolt is provided on

each motor terminal stud; use the factory supplied

Belleville washers on the wire lug connections. The

figure below illustrates the juncture between a motor

terminal stud and terminal lug.

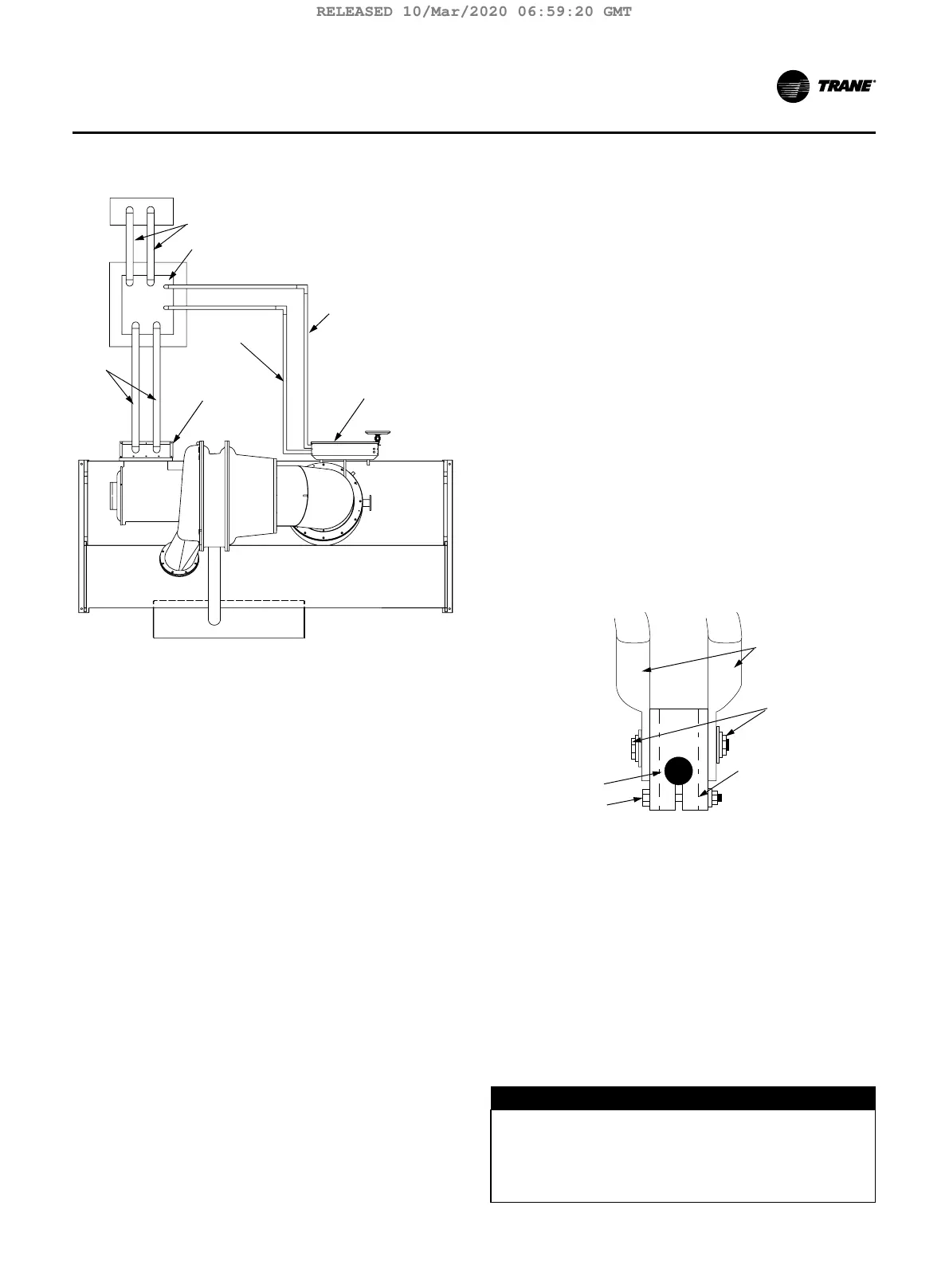

Figure 23. Terminal stud, clamp and lug assembly

2

1

3

4

5

1. Belleville washer

2. Terminal lugs

3. Terminal clamp

4. Motor terminal stud

5. 3/8” bolt

1. Torque for this assembly is 24 ft·lb (32.5 N·m).

2. Install but do not connect the power leads between

the starter and compressor motor. (These connec-

tions will be completed under supervision of a quali-

fied Trane service engineer after the pre-start inspec-

tion.)

D

NOTICE

Component Damage!

Ensure the power supply wiring and output to motor

wiring are connected to the proper terminals. Failure

to do so will cause catastrophic failure of the starter

and, or motor.

TCVHE-SVX04D-EN 45

Power Supply Wiring

RELEASED 10/Mar/2020 06:59:20 GMT

Loading...

Loading...