SS-APG010C-EN

5

Line Sizing, Routing, and Component Selection

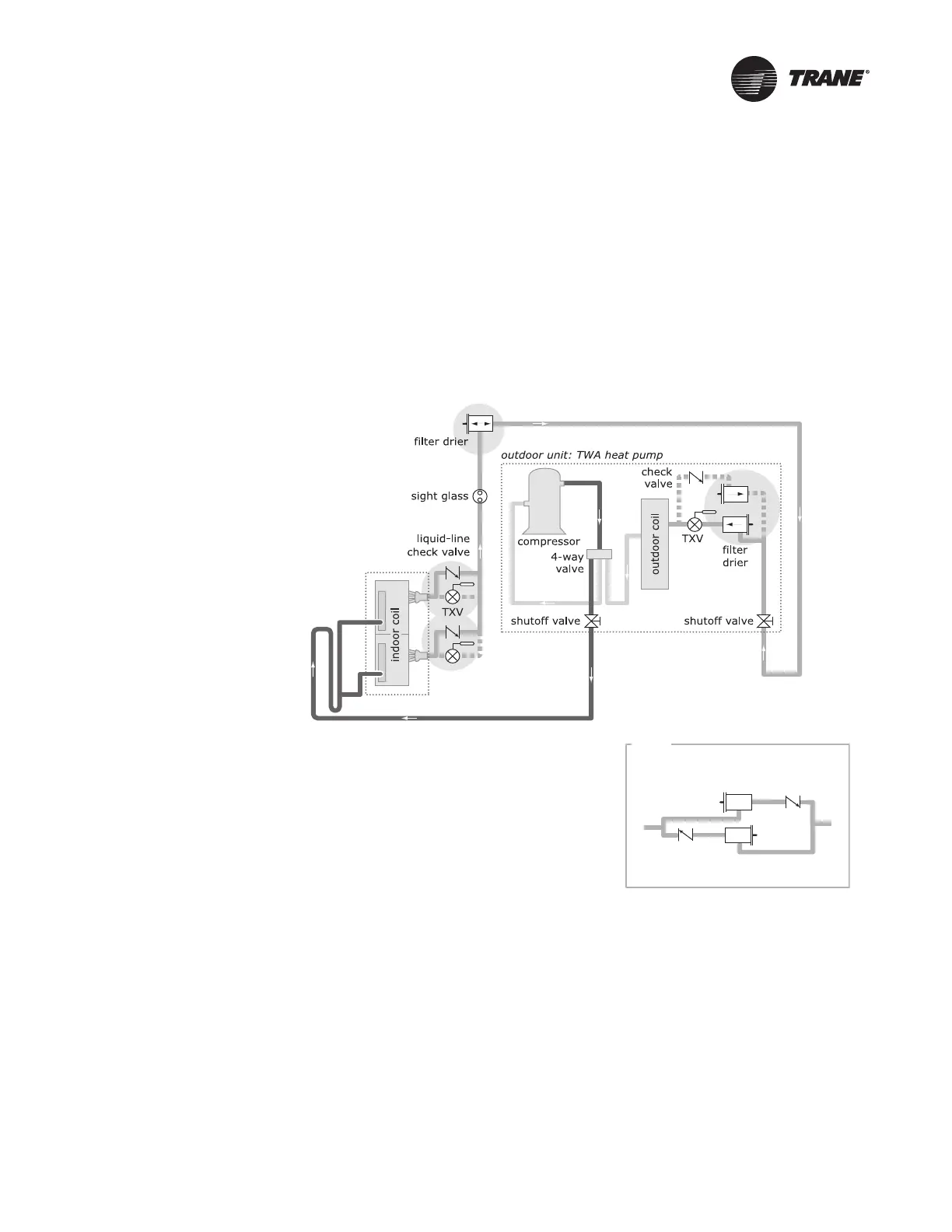

Figure 5 illustrates an example of a (4) TTA/TWA blower coil split system component arrangement.

Use it to determine the proper, relative sequence of the components in the refrigerant lines that

connect the (4) TTA/TWA outdoor unit to the blower coil. Refer to “Refrigerant Piping Examples,”

p. 12, for more detailed schematics of evaporator piping when a single-circuited blower coil is

piped to a single-circuited outdoor unit; when a dual-circuited blower coil is piped to two outdoor

units; or when a dual-circuited blower coil is piped to a single-circuited outdoor unit. All new (4)

TTA/TWA units and BCHC/BCVC units are R-410A products, and all the selected components

installed in the field must also be rated for use with R-410A.

Figure 5. Placement of liquid-line check valves in TWA heat-pump applications when paired

with a BCHC/BCVC blower coil (single circuit shown in heating mode)

Liquid Lines

Line Sizing

Properly sizing the liquid line is critical to a reliable split system application. Table 3, p. 16, shows

the recommended liquid-line sizing for each (4) TTA/TWA model based on its nominal capacity.

Using the preselected tube diameter will maximize the operating envelope and is the line size

around which the installation literature charging charts were generated. Increasing the line size will

not increase the allowable line length.

BCHC/BCVS unit

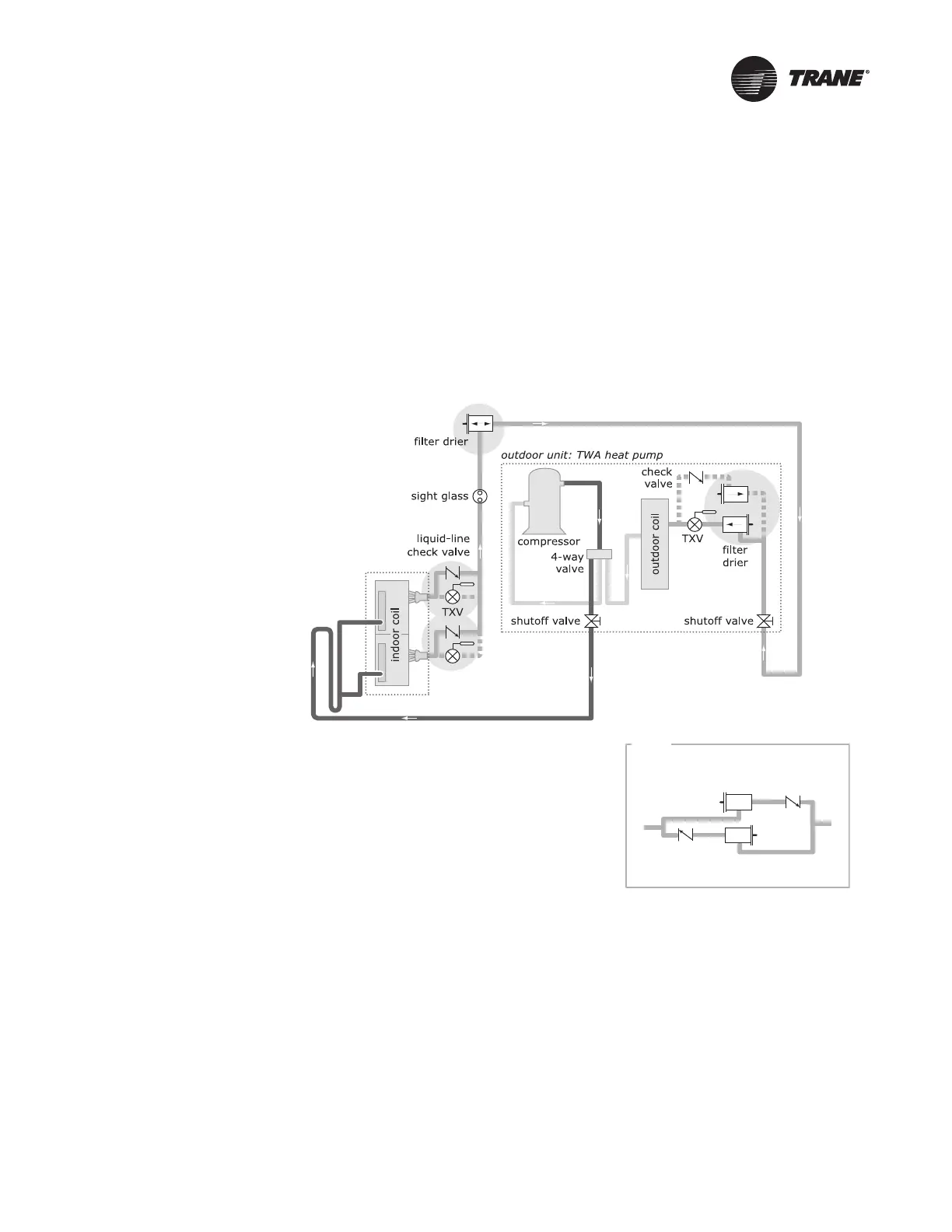

see INSET

INSET

Heat pump liquid line filters

check valve

check valve

Loading...

Loading...