CVHE-SVN04M-EN

23

Figure 11. Vane actuator level on interstage

Figure 12. Vane actuator operator mechanism

WWAARRNNIINNGG

RReeffrriiggeerraanntt MMaayy BBee UUnnddeerr PPoossiittiivvee

PPrreessssuurree!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd

rreessuulltt iinn aann eexxpplloossiioonn wwhhiicchh ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy oorr eeqquuiippmmeenntt ddaammaaggee..

SSyysstteemm ccoonnttaaiinnss rreeffrriiggeerraanntt aanndd mmaayy bbee uunnddeerr

ppoossiittiivvee pprreessssuurree;; ssyysstteemm mmaayy aallssoo ccoonnttaaiinn ooiill..

RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree bbeeffoorree

ooppeenniinngg tthhee ssyysstteemm.. SSeeee uunniitt nnaammeeppllaattee ffoorr

rreeffrriiggeerraanntt ttyyppee.. DDoo nnoott uussee nnoonn--aapppprroovveedd

rreeffrriiggeerraannttss,, rreeffrriiggeerraanntt ssuubbssttiittuutteess,, oorr nnoonn--

aapppprroovveedd rreeffrriiggeerraanntt aaddddiittiivveess..

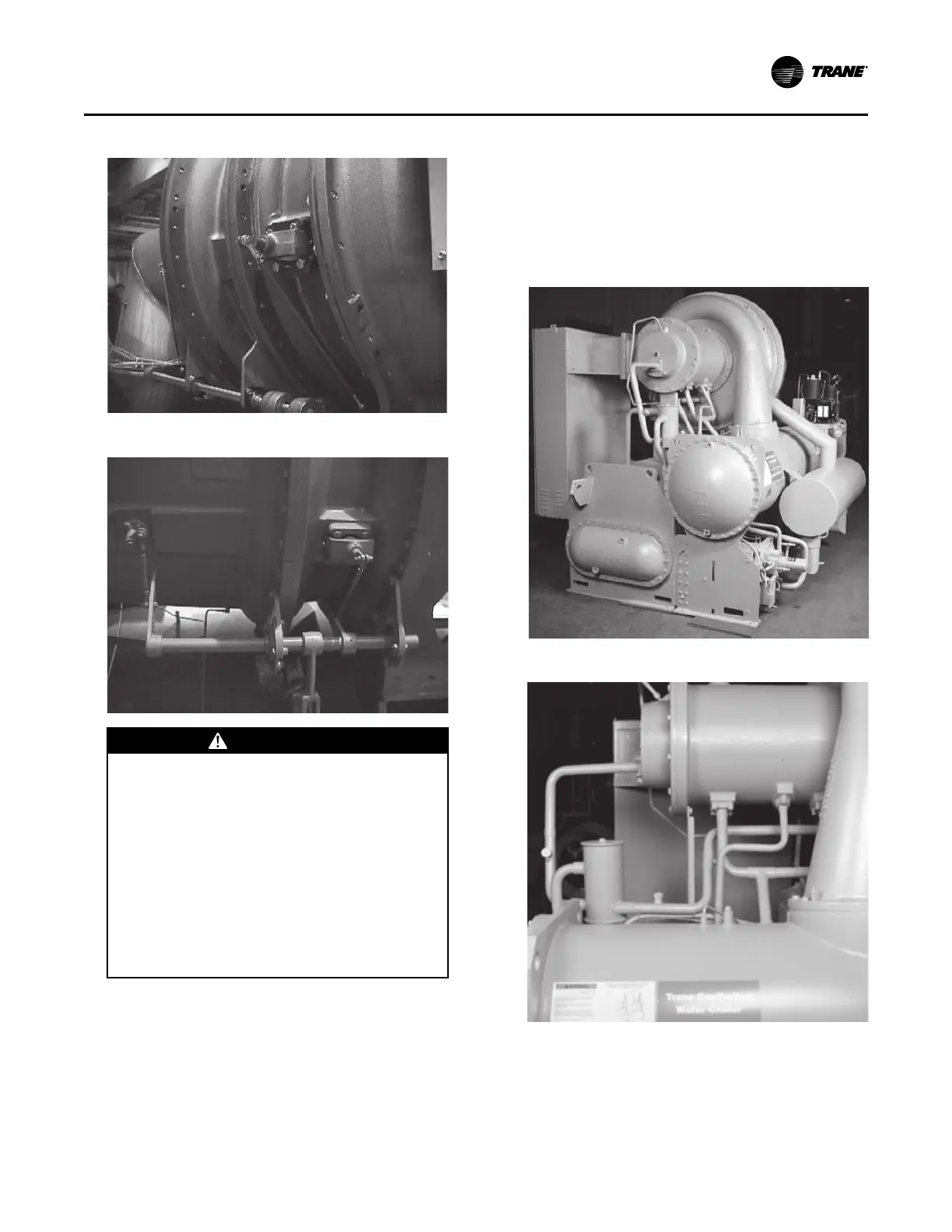

2. Disconnect all external vent lines, motor cooling

supply and drain lines, and oil supply and drain

lines which are connected to the compressor and

compressor motor. Sand all paint off the points

where cuts are to be made. Use a tubing cutter to

ensure that cuts are smooth and square. Figure 13,

p. 23 and Figure 14, p. 23 illustrate these lines.

Couplings will be used to reconnect the lines when

reassembling the chiller. Cap open lines to prevent

entry of foreign material.

NNoottee:: Cover all open connections to avoid

prolonged exposure of oil to humid air.

Remove oil if a chiller is kept in a

disassembled condition for an extended time.

Figure 13. Lubrication system supply, drain, and

vent lines

Figure 14. Lubrication system motor cooling lines

3. Remove the control panel if necessary. Also,

disconnect and remove the unit mounted starter, if

so equipped. See “Control Panel Removal,” p. 27

for instructions.

DDiissaasssseemmbbllyy

Loading...

Loading...