20

6. Maintenance

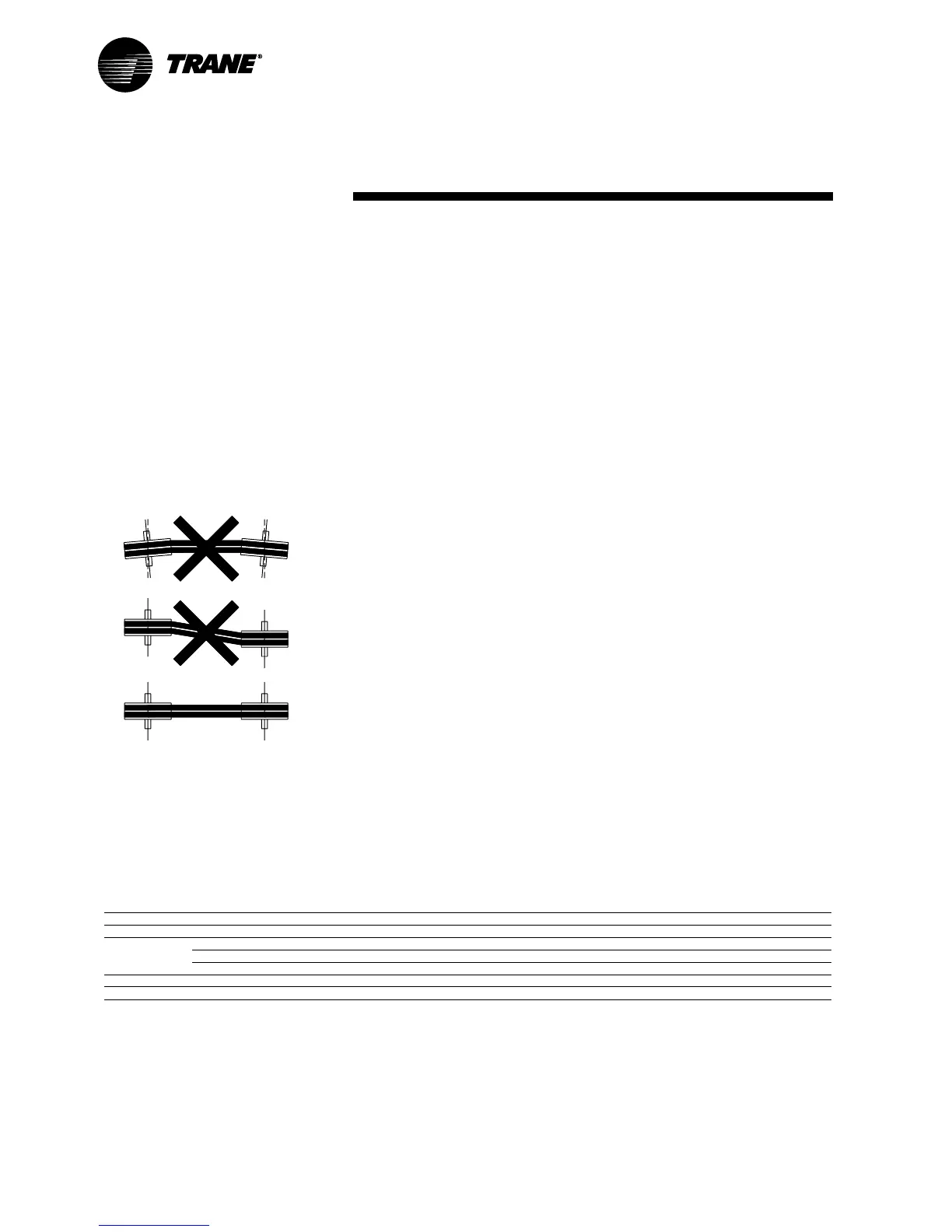

6.6 Belt Replacement

Where a belt guard has been supplied,

please remove the belt guard before

starting work.

To change the belt (or belts), first move

the motor towards the fan by a sufficient

amount to enable the old belts to be

taken off the pulleys and the new belts to

be put on.

If the belt drive has more than one belt,

replace all belts at the same time (see

Figure 21). In such cases, use matched

belts, such as sets in which all belts are

exactly the same lengths.

Tension the belts as per Section 6.5.

Figure 21

Fenner is a registered trademark of J H

Fenner & Co Ltd.

Taper Lock and P B (Precision Built) are

registered trademarks of F P T Group.

Reproduced with permission of F P T

Group.

TO INSTALL

1. Remove the protective coating from

the bore and outside of bush, and bore

of hub. After ensuring that the mating

tapered surfaces are completely clean

and free from oil or dirt, insert bush in

hub so that holes line up.

2. Sparingly oil thread and point of grub

screws, or thread and under head of

cap screws. Place screws loosely in

holes threaded in hub.

3. Clean shaft and fit hub to shaft as one

unit and locate in position desired,

remembering that bush will nip the

shaft first and then hub will be slightly

drawn onto the bush.

4. Using a hexagon wrench, tighten

screws gradually and alternately to the

torques shown in Table 3.

5. Hammer against large end of bush,

using a block of sleeve to prevent

damage. (This will ensure that the bush

is seated squarely in the bore.) Screws

will now turn a little more. Repeat this

alternate hammering and screw

tightening once or twice to achieve

maximum grip on the shaft.

6. If a key is to be fitted, place it in the

shaft keyway before fitting the bush. It

is essential that it is a parallel key and

side fitting only, and has TOP

CLEARANCE.

7. After the drive has been running under

load for a short time, stop and check

tightness of the screws.

8. Fill empty holes with grease to exclude

dirt.

TO REMOVE

1. Slacken all screws by several turns.

Remove one or two according to the

number of jacking off holes. Insert

screws in jacking off holes after oiling

thread and point of grub screws or

thread and under head of cap screws.

2. Tighten screws alternatively until bush

is loosened in hub and assembly is

free on shaft.

3. Remove assembly from shaft.

Table 3 – Torque Settings

Bush Size 1008 1108 1210 1610 2012 2517 3020 3525 4030 4535 5040

Screw Tightening Torque (Nm) 5.6 5.6 20 20 30 50 90 115 170 190 270

Screw Details Quantity 22222 223 3 33

Size (BSW) 1/4" 1/4" 3/8" 3/8" 1/16" 1/2" 5/8" 1/2" 5/8" 3/4" 7/8"

Hexagon Socket Size (mm) 33555 6810121414

Large End Diameter (mm) 35.0 38.0 47.5 57.0 70.0 85.5 108.0 127.0 146.0 162.0 177.5

Approximate Mass (kg) 0.1 0.1 0.2 0.3 0.7 1.5 2.7 3.8 5.6 7.5 11.1

Fenner is a registered trademark of J H Fenner & Co Ltd.

Taper Lock and P B (Precision Built) are registered trademarks of F P T Group.

Reproduced with permission of F P T Group.

CLCH-SVX05A-GB

Loading...

Loading...