Installation

SO-SVN037A-EN 21

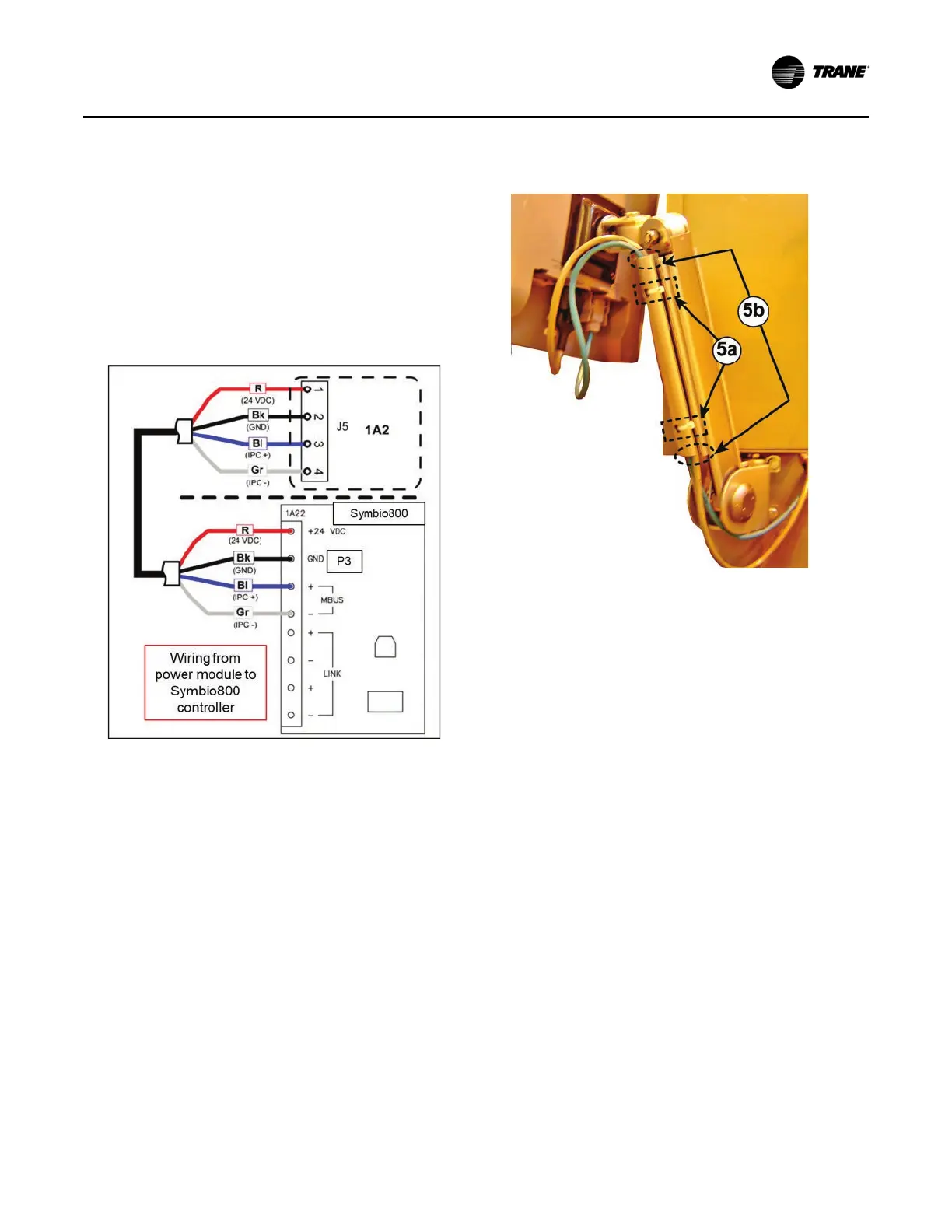

4. Connect the Symbio 800 controller to the 1A2 power

supply using the length of 4-conductor cable provided:

a. Connect each of the 4 individual wires on one end of the

cable to the correct terminal of the removable J5

terminal plug on the 1A2 power supply.

b. Route the other end of the cable inside of the cabinet

over to the Symbio 800 controller and connect each of

the 4 individual wires to the correct terminals on the

controller.

Notes:

• R. Red wire for 24 Volts direct current

• Bk. Black wire for ground

• Bl. Blue wire for IPC+ connection

• Gr. Gray wire for IPC-connection

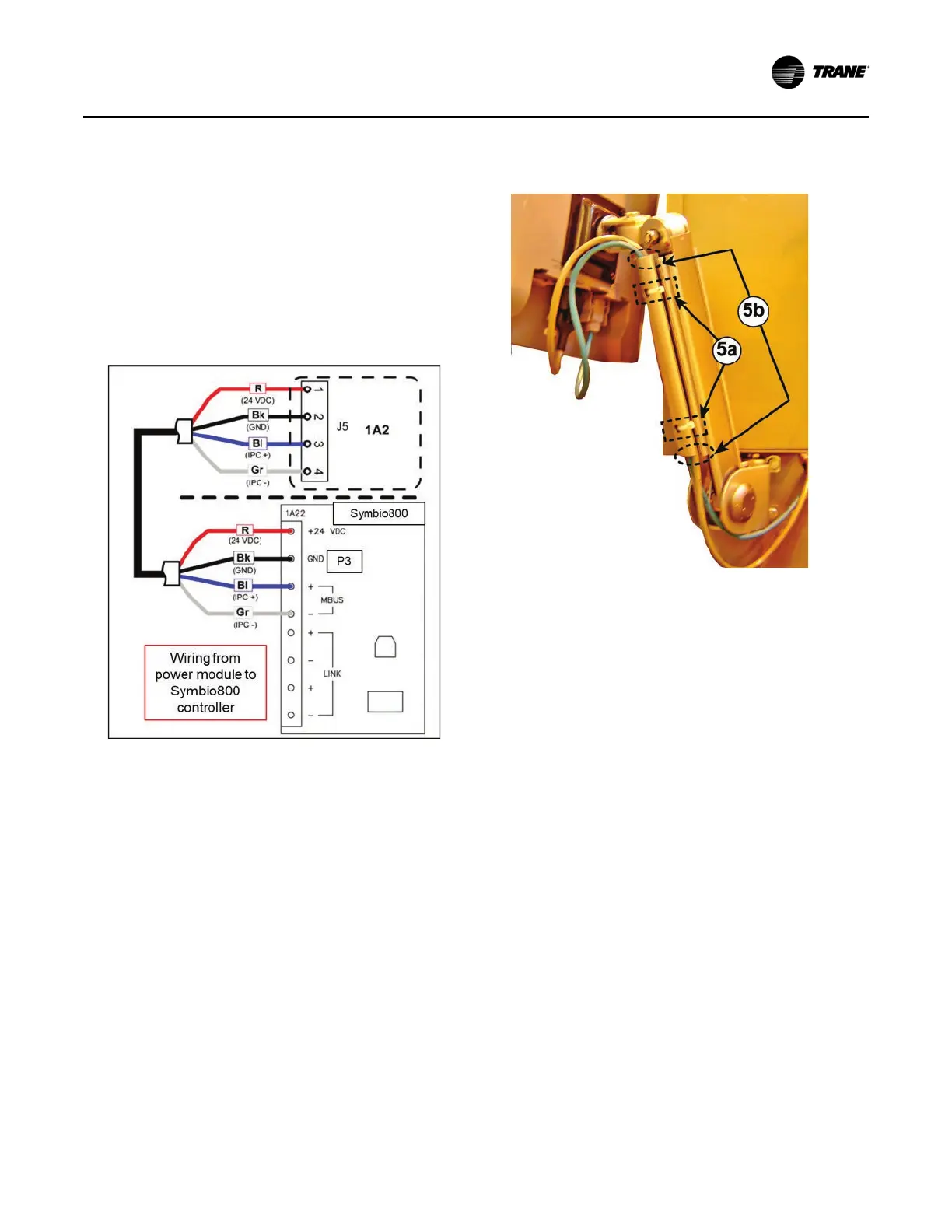

5. Secure all cables in the wire channel on the display arm

with cable ties:

There are 2 factory-drilled holes provided in the wire

channel to aid in neatly securing the cables with cable ties

as is recommended.

Important: Wire protection may be required at both ends of

the wire channel and at the door hinge opening

on the control panel enclosure due to the

potential presence of sharp edges that could

abrade or cut the wires.

6. Use cable ties to clean up and secure wiring runs inside of

the control panel enclosure.

Solid State Oil Heater Relay

Installation

Note: This procedure does not apply to new chillers

operating with R514A refrigerant. Chillers with R514A

refrigerant have solid-state relay for heater control

installed and configured by the factory.

Relay RLY02909 is provided for upgrading chillers with R-123

refrigerant. This relay will operate with a 120V 15mA signal, yet

it will safely and quickly switch 120V loads up to 25 amps. The

oil heater’s amp draw is 6.25 amps at 120V, which is well within

the capacity of RLY02909.

Mounting Location

The RLY02909 must be mounted directly onto a flat steel face

of the control panel, either on a side wall of the enclosure, or

on the back-plane panel. The mounting surface acts as a heat

sink for the relay, so the relay should be securely bolted to the

mounting surface.

Note: Instructions included with the relay may require

removal of paint from the mounting surface, and the

use of a heat conductive paste between the relay and

the mounting surface. Trane’s lab testing indicates that

these additional steps are not needed for the low 6 or

7 amp draw that our heater will apply to the relay.

Securely mounting the relay to any steel surface in the

control panel is adequate for our application.

Figure 31. Wire connections from 1A2 power supply J5

to Symbio 800 controller

Figure 32. Neatly secure and protect cables in display

arm wire channel

Loading...

Loading...