Start-Up

94 OAU-SVX007A-EN

modulating sections, the outlet gas pressure from main/

regulator valve into the modulating valve is 5-in. WC.

Main On-Off valves in 1/2-in. gas line require 3/32-in. Allen

wrench to adjust outlet gas pressure. Valves in

3/4-in. gas line require flat blade screwdriver to adjust

outlet gas pressure. Following these sequences, inducer

speed will reduce to low speed and will now be speed-

controlled by the heater controller based on gas input to

burners.

With heating command at 100 percent and with a single

split manifold heater installed, the On-Off section of the

heater will require the modulating section to prove ON

before the On-Off section will enable. Inducer speed high

at all times the On-Off section is in ignition sequence or

firing. On-Off section sequence includes a 1-second

ignition pre-purge followed by 4-second ignition trial.

Ignition or flame failure will be followed by 30-second inter-

purge for two ignition retry then 5-minute lockout period if

both retry attempts fail. Correct manifold gas pressure for

On-Off heater section is 3.5-in. WC.

For units including an additional separate On-Off heater,

set heat command output to 49 percent to run modulating

heater startup. When complete with modulating heater

startup, increase heat output command to 100 percent to

start up the second heater.

High Fire and Low Fire Adjustment

To adjust high fire or low fire setting, please refer to EXA

STAR modulating valve document. This document will ship

with all gas heat units.

Failure to Ignite

• On the initial startup, or after unit has been off long

periods of time, the first ignition trial may be

unsuccessful due to need to purge air from manifold at

startup.

• If ignition does not occur on the first trial, the gas and

spark are shut-off by the ignition control and the control

enters an inter-purge period of 15 seconds, during

which the draft inducer continues to run.

• At the end of the inter-purge period, another trial for

ignition will be initiated.

• Control will initiate up to three ignition trials on a call for

heat before lockout of control occurs.

• Control can be brought out of lockout by cycling call for

heat at the main unit display.

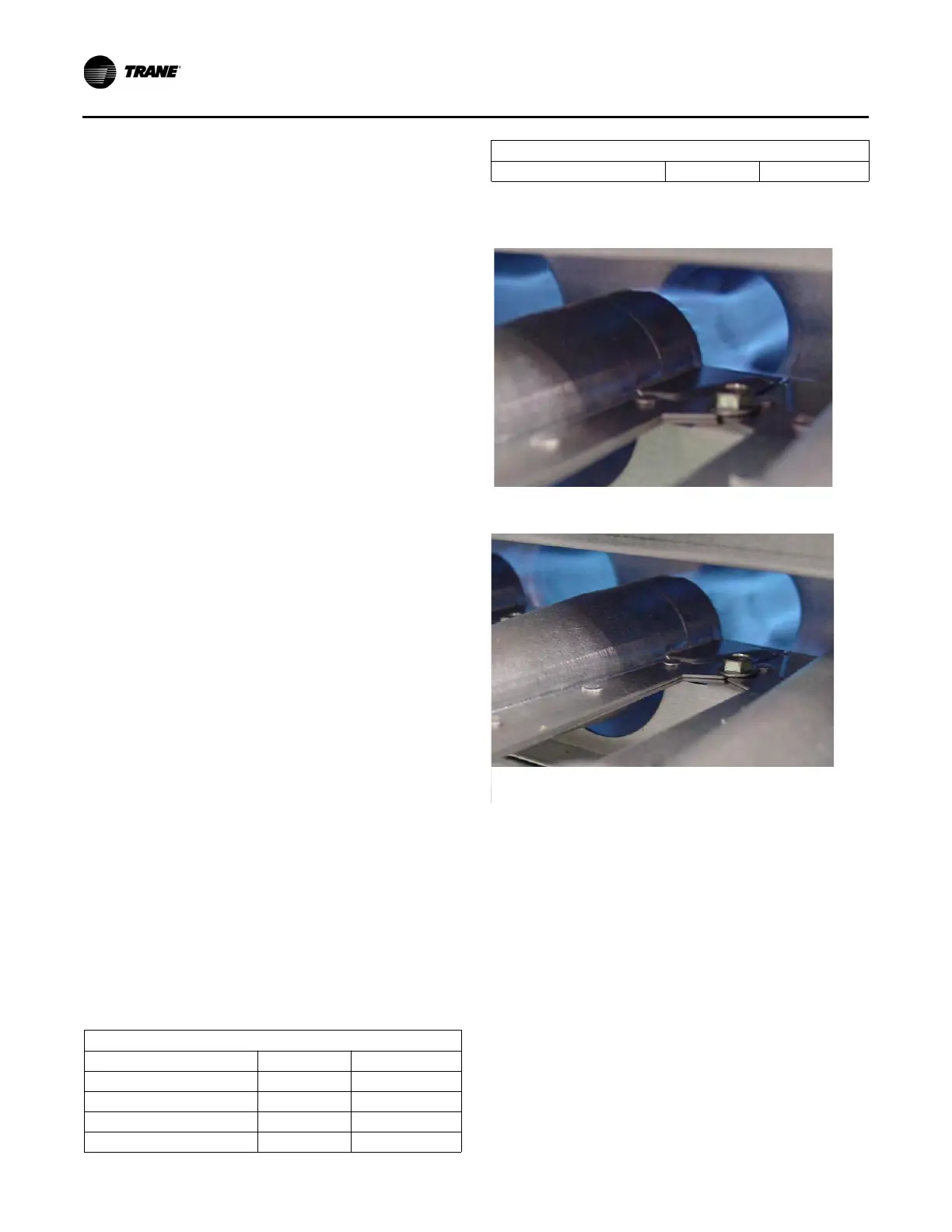

Prior to completing the startup, check the appearance of

the main burner flame. Refer to Figure 143 for flame

characteristics of properly adjusted natural gas systems.

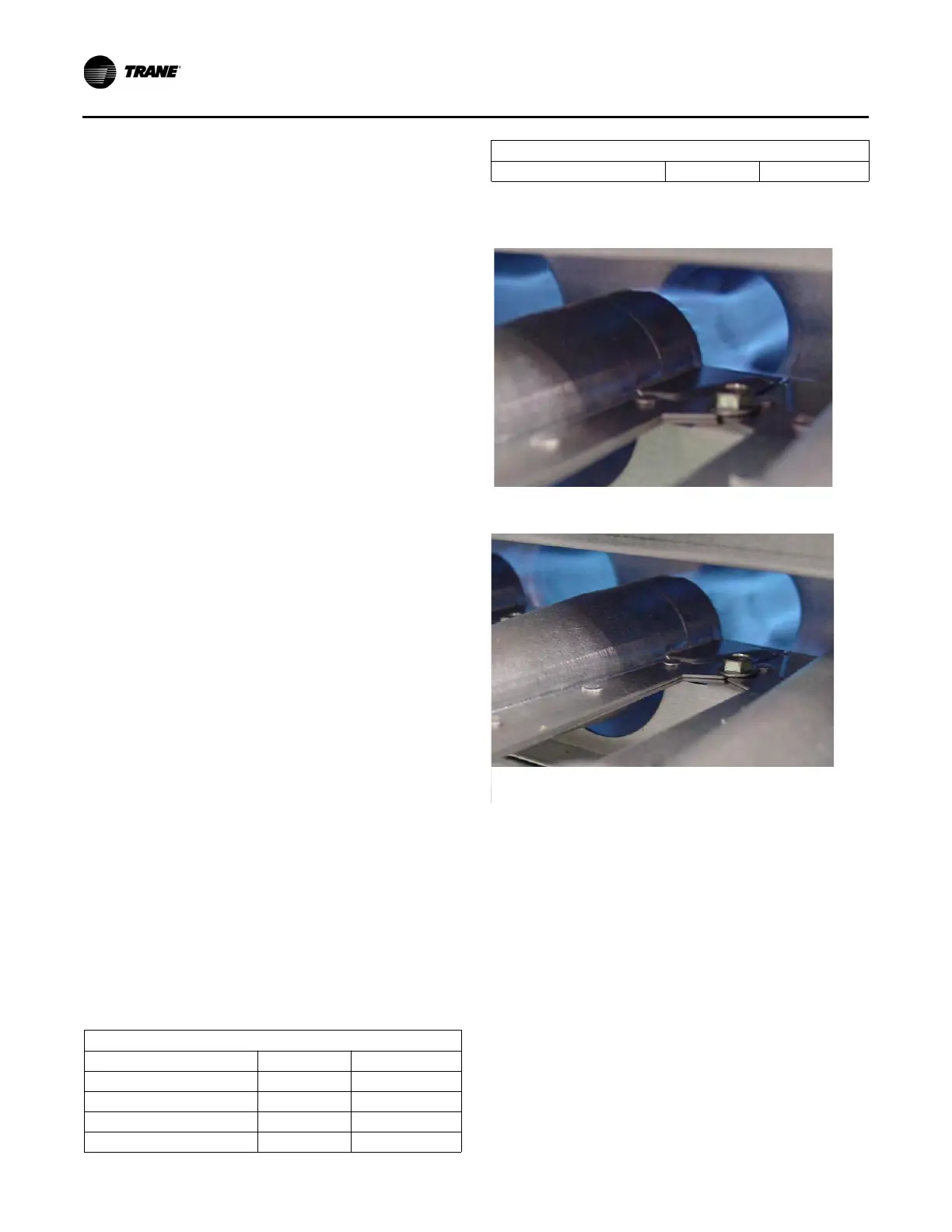

Main Burner Flame

• The burner flame should be predominately blue in color

and well defined and centered at the tube entry as

shown in Figure 143 above. Distorted flame or yellow

tipping of natural gas flame, or a long yellow flame on

propane, may be caused by lint and dirt accumulation

inside burner or at burner ports, at air inlet between

burner and manifold pipe, or debris in the main burner

orifice. Soft brush or vacuum clean affected areas.

• Poorly defined, substantially yellow flames, or flames

that appear lazy, indicate poor air supply to burners or

excessive burner input. Verify gas supply type and

manifold pressure with rating plate.

• Poor air supply can be caused by obstructions or

blockage in heat exchanger tubes or vent discharge

pipe. Inspect and clean as necessary to eliminate

blockage. Vacuum any dirt or loose debris. Clean heat

exchanger tubes with stiff brush. Poor flame

characteristics can also be caused by flue gas

Pressure Settings

Fuel Type NG LP

Unit Inlet (in.) 7-14 10-14

Modulating Valve Inlet (in.) 5.0 10.0

Manifold (in.) 3.5 8.0

Low Fire (in.) 0.4 0.8

High Fire (in.) 3.5 8.0

Figure 143. Flame characteristics of properly-adjusted

natural gas systems

Pressure Settings

Burner flame at startup: 1.2-in. WC manifold pressure draft

inducer—high speed

Burner flame at high fire: 3.5-in. WC manifold pressure draft

inducer—high speed

Loading...

Loading...