25

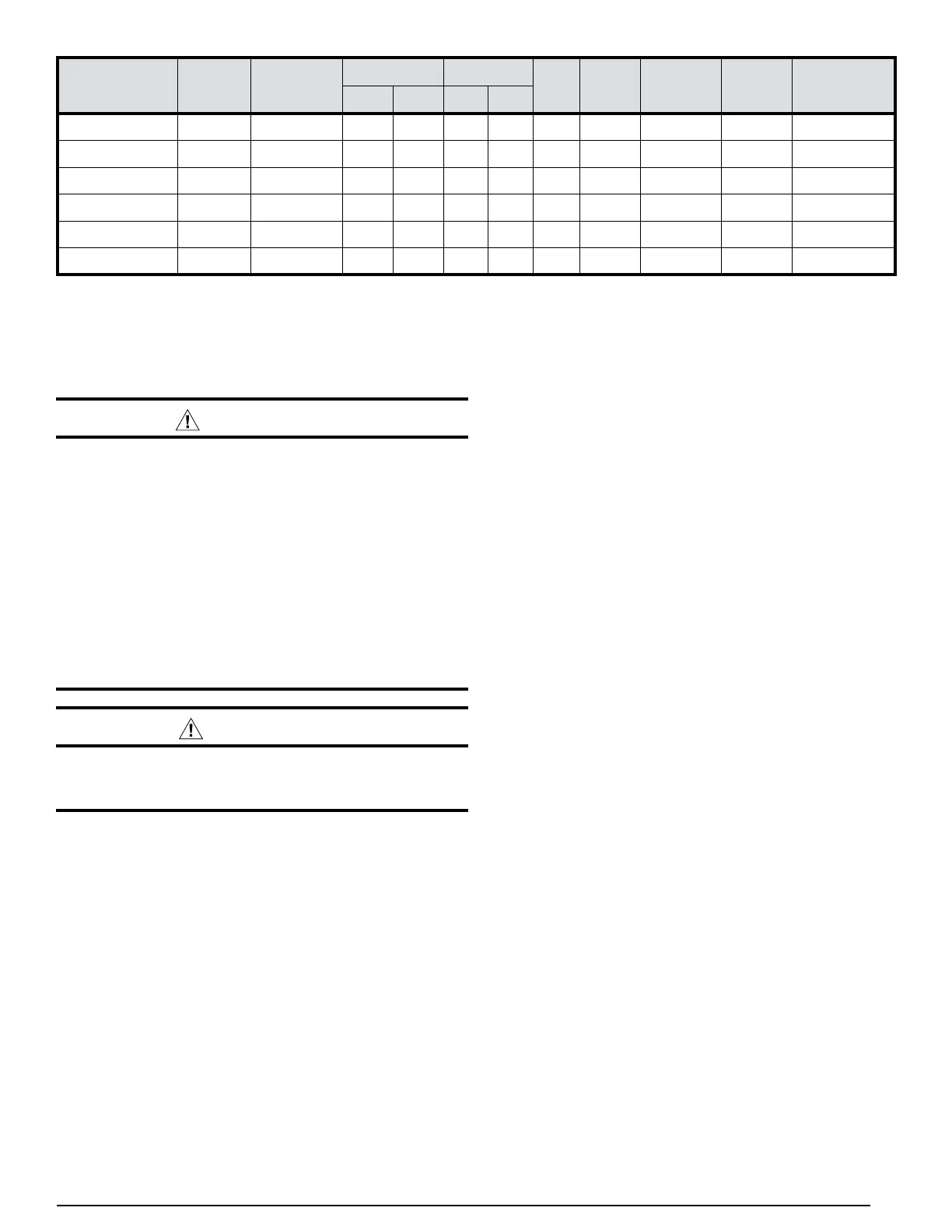

Table 9. Electrical Data.

MODEL

NUMBER

HEATING

INPUT

(BTUH)

NOMINAL

ELECTRICAL

SUPPLY

VOLTAGE RANGE COMPRESSOR

FAN

AMPS

BLOWER

MOTOR

AMPS

INDUCER

MOTOR

AMPS

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

OVER-CURRENT

PROTECTION

MIN. MAX. RLA LRA

4YCL4024A1055A 55,000 230-60-1 196 253 12.8 58.3 1.0 3.8 0.7 20.8 30

4YCL4030A1070A 70,000 230-60-1 196 253 15.7 73 1.46 5.4 0.7 26.5 40

4YCL4036A1070A 70,000 230-60-1 196 253 18.6 79 1.46 5.4 0.7 30.1 45

4YCL4042A1100A 100,000 230-60-1 196 253 22.1 109 1.46 5.4 0.7 34.5 50

4YCL4048A1100A 100,000 230-60-1 196 253 24.3 117 1.46 5.4 0.7 37.2 60

4YCL4060A1100A 100,000 230-60-1 196 253 29.3 134 1.46 7.0 0.7 45.2 70

NOTE: FLA = Full Load Amps; LRA = Lock Rotor amps; RLA = Rated Load Amps.

REFRIGERANT CHARGING

WARNING:

These units are shipped fully charged with R-410A

refrigerant and ready for installation. When a system

is installed according to these instructions, no

refrigerant charging is required. If repairs make it

necessary for evacuation and charging, it should

only be done by qualified, trained personnel

thoroughly familiar with this equipment. Some

local codes require licensed installation/service

personnel to service this type of equipment. Under

no circumstances should the owner attempt to install

and/or service this equipment. Failure to comply

with this warning could result in property damage,

personal injury, or death.

CAUTION:

This unit uses R-410A refrigerant. DO NOT use any

other refrigerant in this unit. Use of another refrigerant

may damage the unit.

The system refrigerant charge can be checked and adjusted

through the service ports provided at the front panel. Use

only gauge lines which have a “Schrader” depression device

present to actuate the valve. Draw a vacuum on gauge lines

to remove air before attaching them to the service ports on the

unit. Refrigerant charging must be done by qualified personnel

familiar with safe and environmentally responsible refrigerant

handling procedures.

Application Notes & Charging Charts

(Cooling Mode Only)

This equipments cooling system contains refrigerant under

high pressure, always use safe practices when servicing the

unit. Always review the factory literature and safety warnings

prior to servicing.

These units are shipped from the factory with the proper

amount and type of refrigerant. Always inspect the unit rating

label to determine the units information prior to working on the

system. Do not mix different refrigerants or charge the unit

with a refrigerant not listed on the unit rating label.

The charging tables are valid for a variety of indoor, return

air conditions and are most highly influenced by the outdoor

ambient temperature, outdoor fan operation and the unit

operating voltage. Before referencing the charts, always make

sure that the compressor circuit is energized on nominal speed

(Y1 energized) and has stable operation. As can be seen in

the charging charts, the ideal system sub-cooling can vary

over the range of operation. Always reference the charts to

determine the ideal amount of sub-cooling for a given liquid

pressure. Units charged to other values will not perform at the

rated unit efficiency (EER). For 2 - 4 ton units, see Table 10

(page 26), Table 11 (page 26), Table 12 (page 27),

Table 13 (page 27), & Table 14 (page 28). For 5 ton units

see Figure 13 (page 28).

To inspect a systems operation, using quality instruments,

match the measured liquid temperature to the units chart.

The measured liquid pressure reading should be within 3%

of the value shown for most installations.

For systems that are operating with more then a 5% deviation,

inspect the unit for leaks. Always use safe and environmentally

sound methods for refrigerant handling. When repairing system

leakages, always utilize a nitrogen (inert) gas to protect the

refrigerant system and pressure check the repair before re-

charging. Always replace the filter-dryers when performing

any repair to the refrigeration system. After completing the

repairs, evacuate the system to 350-500 microns and weigh in

the refrigerant to the amount specified on the unit rating label.

Loading...

Loading...