68

SS-SVX11K-EN

NNOOTTIICCEE

CCoommppoonneenntt FFaaiilluurree!!

RReessiissttaannccee iinn eexxcceessss ooff 33 oohhmmss ppeerr ccoonndduuccttoorr

ccoouulldd rreessuulltt iinn ccoommppoonneenntt ffaaiilluurree dduuee ttoo

iinnssuuffffiicciieenntt AACC vvoollttaaggee ssuuppppllyy..

DDoo nnoott eexxcceeeedd tthhrreeee ((33)) oohhmmss ppeerr ccoonndduuccttoorr ffoorr

tthhee lleennggtthh ooff tthhee rruunn..

Before installing any connecting wiring, see drawings

in the Dimensions and Weights chapter for the

electrical access locations provided on the unit and

table below for AC conductor sizing guidelines, and;

• Use copper conductors unless otherwise specified.

• Ensure that the AC control wiring between the

controls and the unit’s termination point does not

exceed three (3) ohms/conductor for the length of

the run.

• Be sure to check all loads and conductors for

grounds, shorts, and miswires.

• Do not run the AC low voltage wiring in the same

conduit with the high voltage power wiring.

Typical Low voltage components may include:

• Zone thermostat wiring (AC & DC wiring)

• System control switch wiring (VAV units)

• Night setback relay wiring (VAV units)

• Economizer actuator circuit wiring (VAV units)

• Discharge air sensor wiring (VAV units)

• Jumpers for hot gas bypass operation

• Chilled water temperature sensor (EVP units)

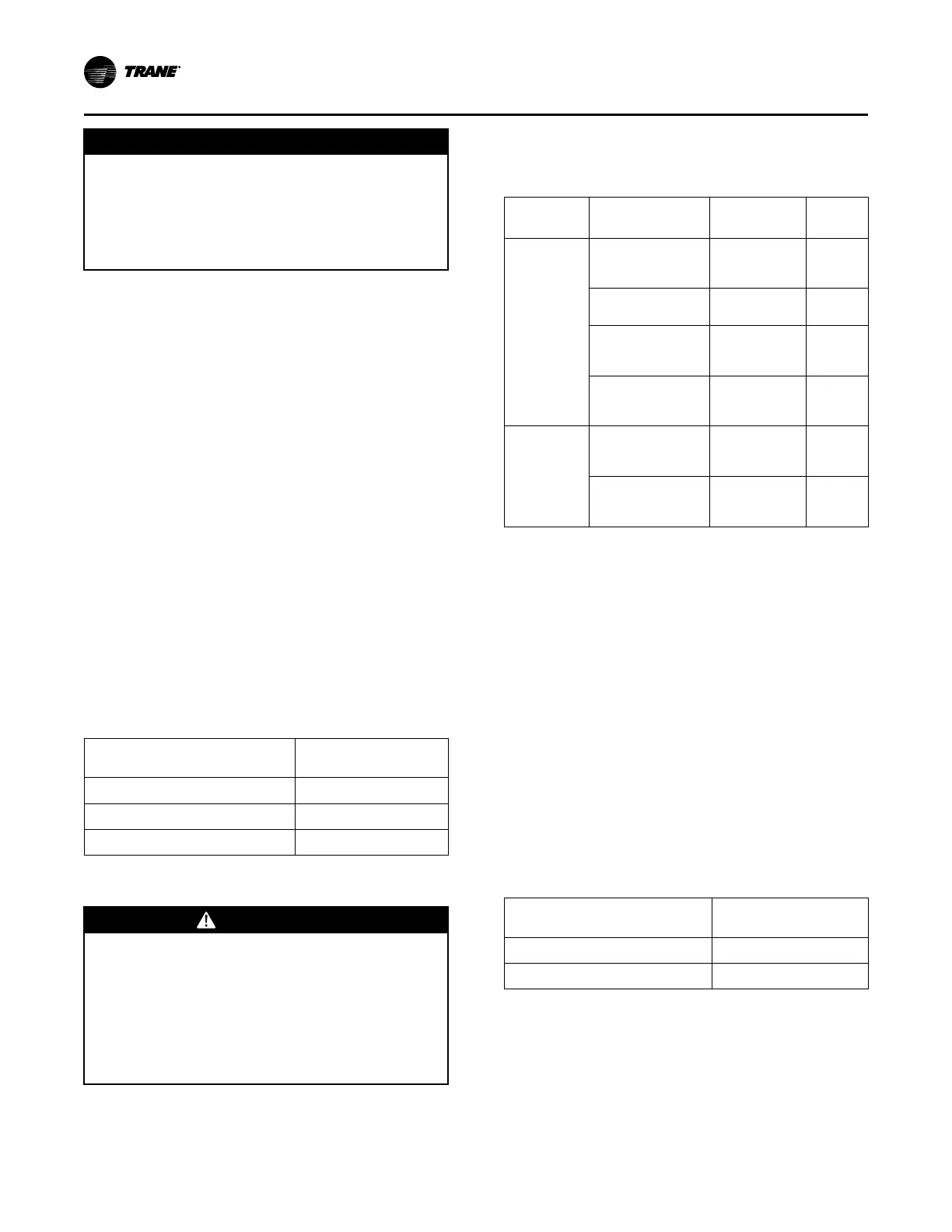

Table 22. AC conductors

Distance from Unit to Control

Recommended

Wire Size

000 - 460 feet

18 gauge

461 - 732 feet

16 gauge

733 - 1000 feet

14 gauge

Controls — DC Analog Input/Outputs

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaann nnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. VVeerriiffyy tthhaatt nnoo

ppoowweerr iiss pprreesseenntt wwiitthh aa vvoollttmmeetteerr..

Before installing any connecting wiring between the

unit and components utilizing a DC analog input/

output, see drawings in Dimensions and Weights

chapter for the electrical access locations provided on

the unit.

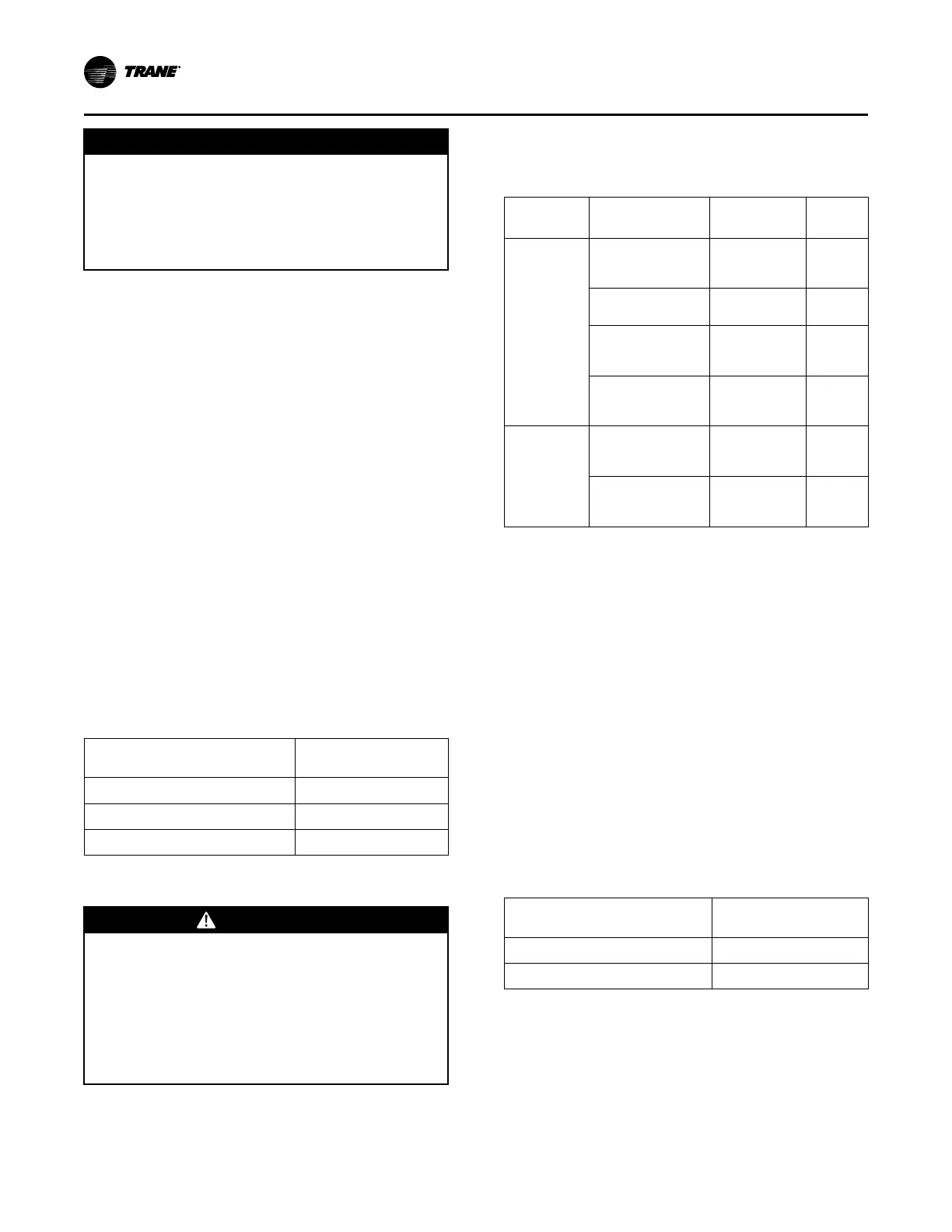

Table 23. Components

Unit Size

(tons)

Component

(a)

Designation Unit

Type

20 to 60 Field installed

Discharge Duct

Sensor

6RT1 CV

Field installed

Return Duct Sensor

6RT6 CV

Field installed

Discharge Air

Sensor

6RT3 VAV

Field installed

Chilled Water

Sensor

6RT2 EVP

80 to 120 Field installed

Discharge Air

Sensor

8RT3 VAV

Field installed

Chilled Water

Sensor

8RT2 EVP

(a)

Units may include the listed components. Not all components will be

selected on all units.

• Wiring for the components utilizing a DC analog

input/output signal must be shielded cable (Belden

8760 or equivalent). Ground the shield at one end

only.

• Table below lists the conductor sizing guidelines

that must be followed when interconnecting a DC

binary output device to the unit.

NNoottee:: Resistance in excess of 2.5 ohms per

conductor can cause deviations in the

accuracy of the controls.

• Ensure that the wiring between the binary controls

and the unit’s termination point does not exceed

two and a half (2.5) ohms/conductor for the length

of the run.

• Do not run the electrical wires transporting DC

signals in or around conduit housing high voltage

wires.

Table 24. DC conductors

Distance from Unit to Control

Recommended

Wire Size

000 - 499 feet

16 gauge

500 - 1000 feet

14 gauge

Economizer Actuator Circuit

Each unit ordered with the Constant Volume or

Variable Air Volume control option has the capability of

controlling a field installed economizer. The diagram

below illustrates a typical economizer actuator circuit.

When connecting the economizer actuator control

circuit to the terminal board inside the unit control

IInnssttaallllaattiioonn EElleeccttrriiccaall

Loading...

Loading...