RRU-SVX02F-EN 35

Indirect Gas-Fired Heating Start-Up

Important: The following procedure must be followed

for the unit heating section to function

properly. The following procedures are to

be performed after all electrical and gas

connections to the unit have been

completed and the outdoor air damper and

evaporator fan operation have been verified

and are operating satisfactorily.

Refer to “Sequence of Operation,” p. 18 for additional

information.

Tools Required

• Voltage meter (µA)

•Amp meter

• Gas pressure gauge (2)

• Temperature probe

• Service mirror

• Small refrigeration screwdriver

• 5/16-in. Nut driver

• 1/2-in. Open end wrench

Important: Remove the outdoor air inlet aluminum

mesh filters if they are not clean prior to

proceeding with burner start-up.

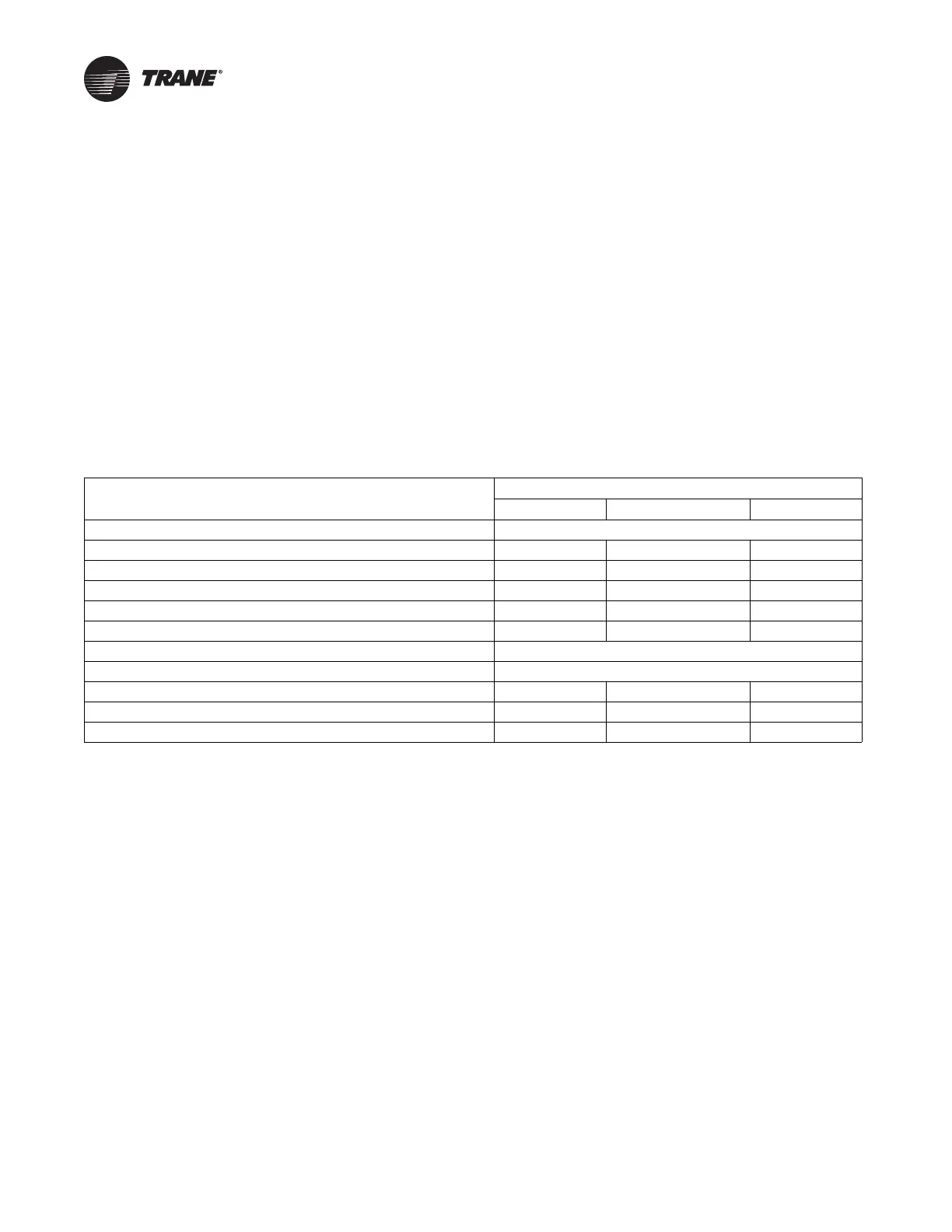

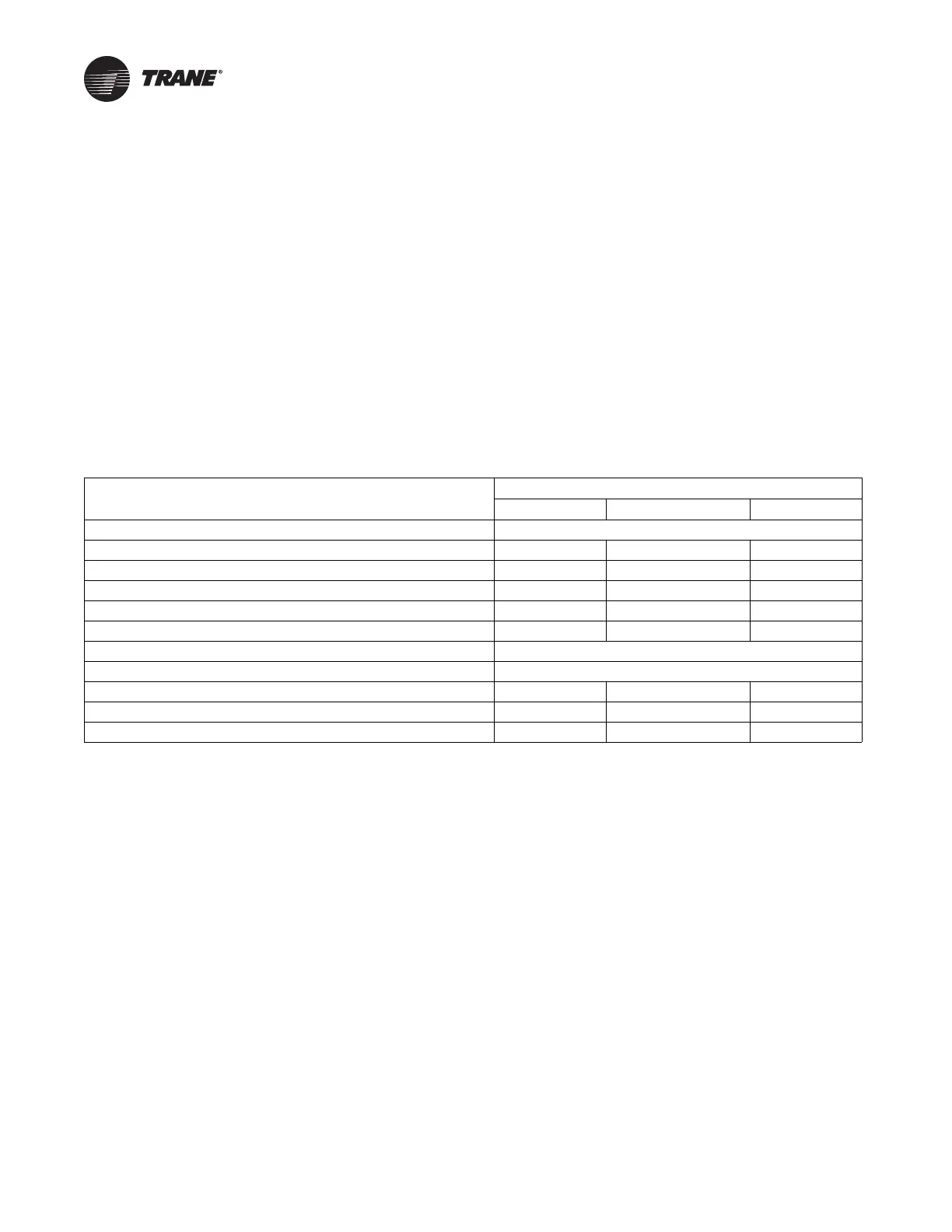

Table 5. Gas heater operating data

Heating Input Rate - BTUH

250,000 350,000 400,000

Fuel Natural Gas ONLY

Minimum Supply Gas Pressure (in. wc) 7 7 7

Maximum Supply Gas Pressure (in. wc) 14 14 14

Maximum (High-Fire) Manifold Gas Pressure (in. wc) 3.9 4.8 5.0

Minimum (Low-Fire) Manifold Gas Pressure (in. wc) 0.041 0.058 0.058

Combustion Blower SuctionPressure (Min. to Max. With Gas Valve Closed) -4.3 to -2.5 in. wc -4.3 to -1.7 in. wc -4.3 to -1.5 in. wc

Minimum Flame Sensing Current 1.5 Microamps DC

Normal Sensing Current Range 3.0 to 6.0 Microamps DC

RRUCM Voltage Output Range to MGA (Vdc) 2.0 to 4.0 2.0 to 5.2 2.0 to 8.0

Flue Gas Temperature Rise Above Ambient (°F) 180 to 200 280 to 300 350 to 370

Flue Gas Content—% CO

2

Natural Low/High 6.0/9.5 6.0/9.5 6.0/10.5

Note: Adjust the combination gas valve regulator gas valve to vary the manifold gas pressure and burner input within the range shown. Do not exceed

pressure as listed in this table, under any circumstances. Use combination readings (CO and O

2

and a flow meter to determine exact inputs.

Loading...

Loading...