Indirect Gas-Fired Heating Start-Up

36 RRU-SVX02F-EN

STEP 1: Confirm Inlet Gas Pressure and Gas

Flow

Close the burner gas train manual shut-off valve located

upstream of the Combination Gas Valve. Connect gas

pressure gauge upstream of the burner gas train manual

shut-off valve. Do NOT expose gas controls to pressures

above 1/2 psi (14 in. wc). Minimum inlet gas pressure

required for full modulation is 1/4 psi (7 in. wc). Refer to

unit data plate for operating gas pressure range. Confirm

gas flow and bleed gas line if needed before proceeding to

the next step.

STEP 2: Burner Starting Sequence and Burner

Ignition

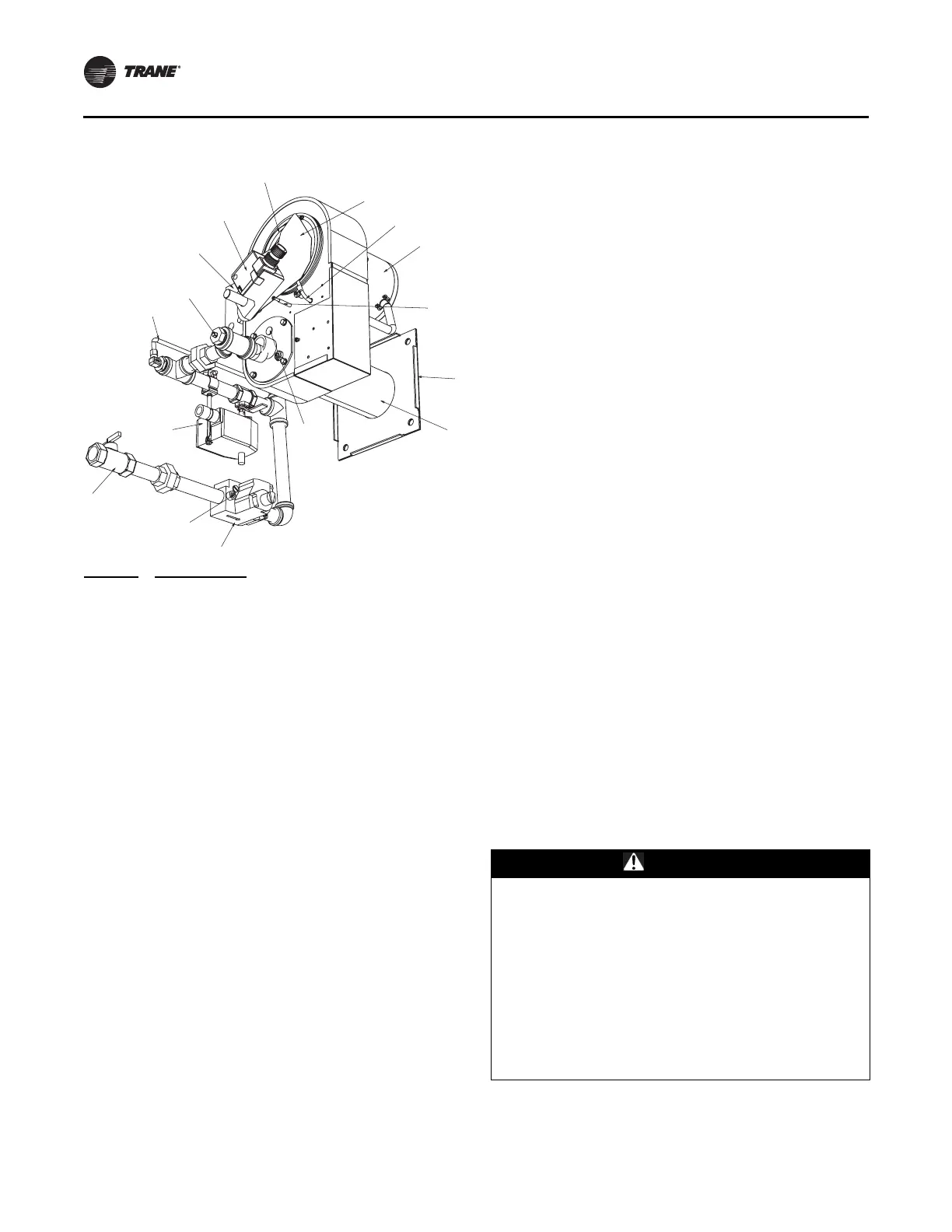

Figure 15 illustrates the gas train main components.

Open burner gas train manual shut-off valve. Open

Combination Gas Valve manual shut-off. At unit ROD

override HEAT binary output ON. Refer to ““Occupied”

Heating Mode,” p. 19 for Burner Starting and Sequence of

Operation. If the burner fails to light or goes out after

lighting, the burner will go into safety lock-out. A single

ignition retry will occur. Power must be turned off to the

RRUCM to initiate another ignition sequence. Use burner

view port to observe burner flame. Proper flame should be

solid blue.

STEP 3: Firing Rate Test

The burner includes a fixed bypass for low-fire operation.

Correct gas pressure assures proper low-fire. Low-fire gas

flow adjustments should not be attempted. The high-fire

firing rate was factory set. If required, adjustments should

only be made by a trained technician. It is recommended

the manufacturer’s technical support team be contacted

prior to making gas flow adjustments.

Override analogue Heat Modulation Signal to check

burner flue gas content. Refer to Table 5, p. 35 for flue gas

content. Override Heat Modulation Signal to 0 to check

low-fire operation and to 100 to check high-fire operation.

The Main Gas Valve regulator would be used to make

high-fire gas flow adjustments. Gas pressure to the burner

is read by connecting gas pressure gauge to the Burner

Gas Pressure Tap.

The Combustion Air Damper set screws are preset at the

locations that correspond with burner low fire and burner

rated high fire capacity. At the low fire setpoint there will

be a slight opening between the damper and the air inlet.

Drill index #40 (0.098 in.) can be used as a reference for the

opening size. Ensure that the damper is flush to the inlet

ring by using a service mirror to check the seal between

the damper and the inlet ring. Minor adjustment can be

done by adjusting the three machine screws on the inlet

ring. Major adjustment can be done by loosening the bolt

(do NOT remove the bolt) only enough for the rod to be

adjusted. In the event that the pressure switch fails to

operate, check the aluminum pick-up tubes to be certain

that the tubes are not obstructed and confirm that the tube

connections to the burner Fan Failure pressure Switch are

tight and secure.

Figure 15. Burner assembly and gas train

PART ID

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

DESCRIPTION

Burner Blower Motor

Combustion Air Inlet

Combustion Air Pressure Tube

Combustion Air Damper

Combustion Damper Actuator

Combustion Damper Hi-Fire Stop

Sight Glass (2)

Burner Gas Pressure Tap

Combination Gas Valve

Gas Regulator (To Burner)

Modulating Gas Valve Actuator

Low Fire Gas Bypass Tube

Electronic Ignition Controller

Burner Mounting Plate

Burner Outlet (Behind Plate Not Shown)

Inlet Manual Shut-Off with Pressure Tap

1

2

$

&

)

'

%

(

+

0

/

*

,

-

3

.

XEH

HU

XDWRU

H6WRS

S

H

HU

XDWRU

EH

ROOHU

H

RW6KRZQ

VVXUH7DS

WARNING

Fire and Carbon Monoxide Hazards!

Failure to follow these instructions could result in death

or serious injury or equipment or property-only

damage.

Do NOT exceed gas supply input beyond rated capacity

as shown on unit data plate as it will result in improper

burner operation. Improper burner operation will cause

the burner to soot and create unsafe operating

conditions, including excessive soot in the flue which

could ignite. Over-firing the burner could also cause

damage to the heat exchanger, which could result in

combustion gases leaking into the occupied space.

Loading...

Loading...