67

RTAA-IOM-3

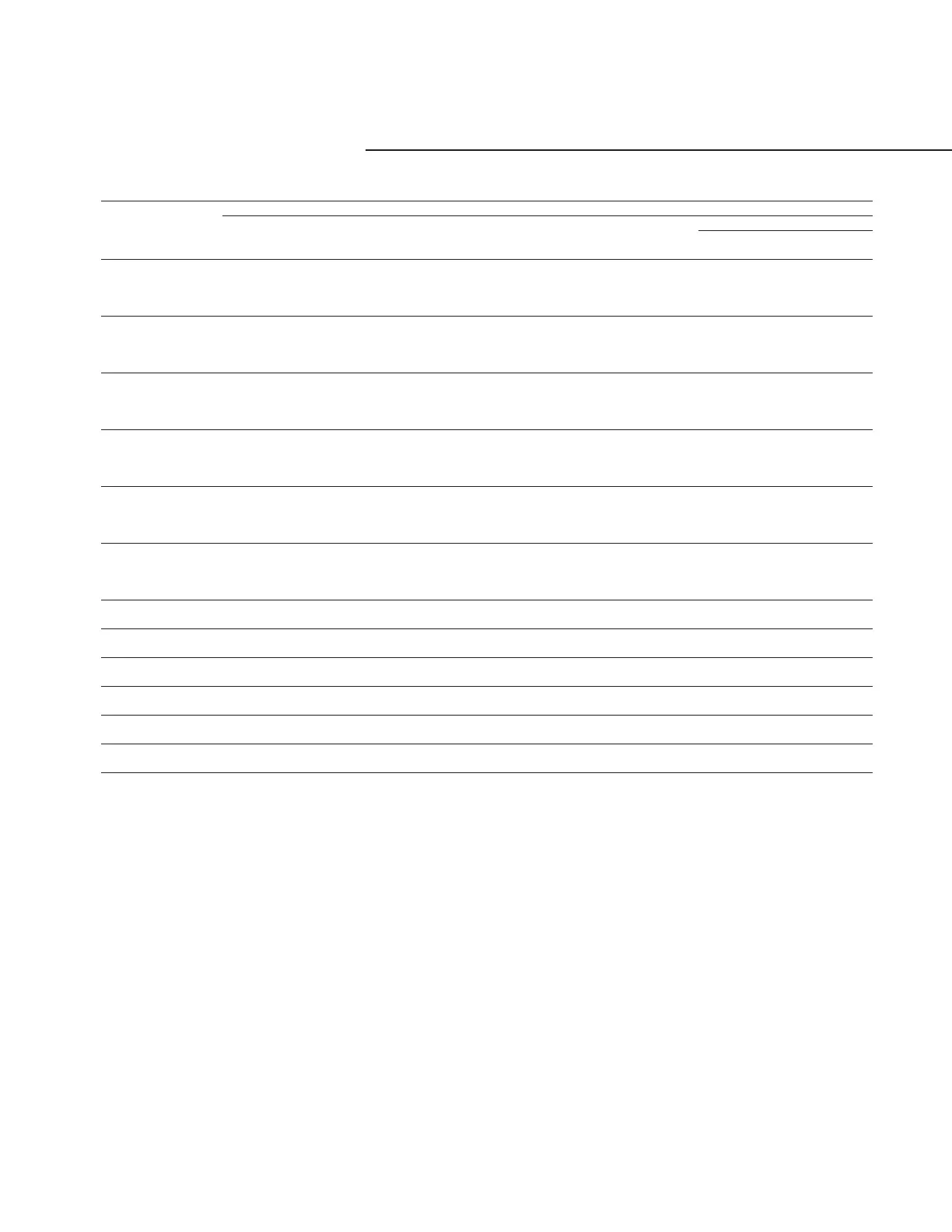

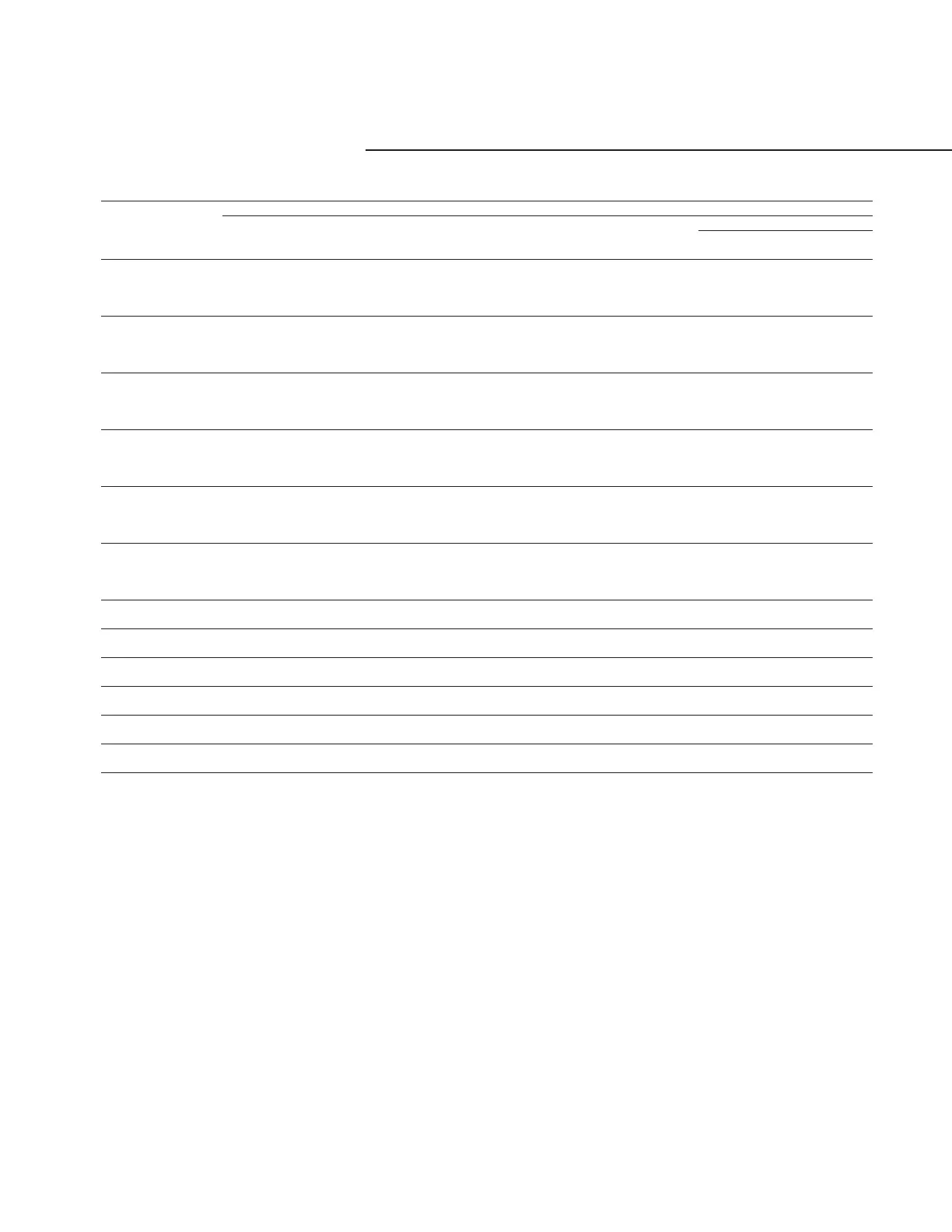

Table 10

Electrical Data

Unit Wiring Motor Data

Fans (Ea)

Rated MCA (3) Rec Time Comp. (Ea) Qty. Qty.

Unit Size Voltage Ckt1/Ckt2(1) MOP(2) Delay or RDE4) Qty. RLA(5) LRA(8) (11) (12) kW FLA kW(7)

RTAA 130 200 383/389 600/600 500/500 2 280/280 1689/1689 10 11 1.3 6.5 0.8

230 383/389 600/600 500/500 2 280/280 1689/1689 10 11 1.3 6.5 0.8

460 306 400 350 2 122/122 633/633 10 11 1.3 2.8 0.8

575 246 300 300 2 98/98 512/512 10 11 1.3 2.3 0.8

RTAA 140 200 383/389 600/600 500/500 2 280/280 1689/1689 10 11 1.3 6.5 0.8

230 383/389 600/600 500/500 2 280/280 1689/1689 10 11 1.3 6.5 0.8

460 306 400 350 2 122/122 633/633 10 11 1.3 2.8 0.8

575 246 300 300 2 98/98 512/512 10 11 1.3 2.3 0.8

RTAA 155 200 422/389 700/600 500/500 2 306/280 2044/1689 11 12 1.3 6.5 0.8

230 422/389 700/600 500/500 2 306/280 2044/1689 11 12 1.3 6.5 0.8

460 322 450 400 2 133/122 766/633 11 12 1.3 2.8 0.8

575 260 350 300 2 107/98 611/512 11 12 1.3 2.3 0.8

RTAA 170 200 515/389 800/600 700/500 2 375/280 2391/1689 12 13 1.3 6.5 0.8

230 515/389 800/600 700/500 2 375/280 2391/1689 12 13 1.3 6.5 0.8

460 363 500 450 2 163/122 896/633 12 13 1.3 2.8 0.8

575 292 400 350 2 131/987 25/512 12 13 1.3 2.3 0.8

RTAA 185 200 515/428 800/700 700/600 2 375/306 2391/2044 13 14 1.3 6.5 0.8

230 515/428 800/700 700/600 2 375/306 2391/2044 13 14 1.3 6.5 0.8

460 376 500 450 2 163/133 896/766 13 14 1.3 2.8 0.8

575 303 400 350 2 131/107 725/611 13 14 1.3 2.3 0.8

RTAA 200 200 514/514 800/800 700/700 2 375/375 2391/2391 14 14 1.3 6.5 0.8

230 514/514 800/800 7001700 2 375/375 2391/2391 14 14 1.3 6.5 0.8

460 406 500 450 2 163/163 896/896 14 14 1.3 2.8 0.8

575 327 450 400 2 131/131 725/725 14 14 1.3 2.3 0.8

RTAA 240 460 303/224 400/350 350/300 3 122-122/163 633-633/896 N/A 17 1.3 2.8 1.0

575 244/180 300/300 300/225 3 98-98/131 512-512/725 N/A 17 1.3 2.3 1.0

RTAA 270 460 360/224 500/350 450/300 3 163-122/163 896-633/896 N/A 19 1.3 2.8 1.0

575 290/180 400/300 350/225 3 131-98/131 725-512/725 N/A 19 1.3 2.3 1.0

RTAA 300 460 406/224 500/350 450/300 3 163-163/163 896-896/896 N/A 21 1.3 2.8 1.0

575 327/180 450/300 400/225 3 131-131/131 725-725/725 N/A 21 1.3 2.3 1.0

RTAA 340 460 303/406 400/500 350/450 4 122-122/163-163 633-633/896-896 N/A 24 1.3 2.8 1.0

575 244/327 300/450 300/400 4 98-98/131-131 512-512/725-725 N/A 24 1.3 2.3 1.0

RTAA 370 460 360/406 500/500 450/450 4 163-122/163-163 896-633/896-896 N/A 26 1.3 2.8 1.0

575 290/327 400/450 350/400 4 131-98/131-131 725-512/725-725 N/A 26 1.3 2.3 1.0

RTAA 400 460 406/406 500/500. 450/450 4 163-163/163-163 896-896/896-896 N/A 28 1.3 2.8 1.0

575 327/327 450/450 400/400 4 131-131/131-131 725-725/725-725 N/A 28 1.3 2.3 1.0

Notes:

(1) Low voltage units (200 & 230 volt) require separate power connections for each circuit.

(2) MOP - Maximum Overcurrent Protection - may be either fused (UL/CSA) or with circuit breakers (CSA only).

MOP = 225 percent of the largest compressor RLA plus 100 percent of the second compressor RLA plus the sum of the condenser fans

FLAs per NEC 440-22.

(3) MCA - Minimum Circuit Ampacity - 125 percent of largest compressor RLA plus 100 percent of second compressor plus the sum of the

condenser fans FLAs per NEC 440-33.

(4) RECOMMENDED TIME DELAY OR DUAL ELEMENT (RDE) FUSE SIZE: 150 percent of the largest compressor RLA plus 100 percent of the

second compressor RLA and the sum of the condenser tan FLAs.

(5) RLA - Rated Load Amps - rated in accordance with UL Standard 465.

(6) Local codes may take precedence.

(7) Control kW includes operational controls only. Does not include heat tapes.

(8) LRA - Locked Rotor Amps - based on full winding start units.

(9) VOLTAGE UTILIZATION RANGE:

Rated Voltage Utilization Range

200 180-220

230 208-254

460 414-506

575 516.633

(10) A 11 5/60/1, 15 amp. customer provided power connection is required to operate the unit controls. A separate 115(60/1, 15 amp. customer

provided power connection is also needed to power the evaporator heat tape (RTAA 130-200 = 420 watts, RTAA 240-400 = 840 wafts @

120 volts) and optional Domestic Water Heater (420 watts @ 120 volts.). If the optional control power is used, the customer needs only to

provide a power connection for the heat tapes.

(11) 15 F minimum starting/operating ambient.

(12) 0 F minimum starting/operating ambient

Loading...

Loading...