RTAC-SVX005A-EN

31

Unit Voltage and Amperage

Checks

WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions when

exposed to live electrical components could result in

death or serious injury.

When it is necessary to work with live electrical

components, have a qualified licensed electrician or

other individual who has been properly trained in

handling live electrical components perform these

tasks.

Electrical power to the unit must meet stringent

requirements for the unit to operate properly. Total voltage

supply and voltage imbalance between phases should be

within the following tolerances.

Voltage Supply

Measure each leg of supply voltage at all line voltage on

circuit breaker. Readings must fall within the voltage

utilization range shown on the unit nameplate. If voltage on

any leg does not fall within tolerance, notify the power

company to correct this situation before operating the unit.

Inadequate voltage to the unit will cause control

components to malfunction and shorten the life of electrical

components and compressor motors.

Voltage Imbalance

Excessive voltage imbalance between phases in a three-

phase system will cause motors to overheat and eventually

fail. Maximum allowable imbalance is 2 percent. Voltage

imbalance is defined as follows:

% Voltage Imbalance =

100 x V

A

— V

D

V

A

where V

A

=

V

1

+V

2

+V

3

(Avg Voltage)

3

• V

1

, V

2

, V

3

= Line Voltages

• V

D

= Line Voltage that deviates the farthest from V

A

.

Example: If the three voltages measured at the line voltage

side of the circuit breaker are 453 volts, 470 volts, and 467

volts, the average (V

A

) would be:

453+470+467

= 463 volts

3

The percentage of imbalance is then:

100 X [463 – 453]

= 2.2%

463

The 2.2 percent imbalance that exists in the example

above exceeds maximum allowable imbalance by 2.0

percent. This much imbalance between phases can equal

as much as 20 percent current imbalance with a resulting

increase in winding temperature that will decrease

compressor motor life.

If the voltage imbalance is over 2 percent, notify the proper

agencies to correct the voltage problem before operating

this equipment.

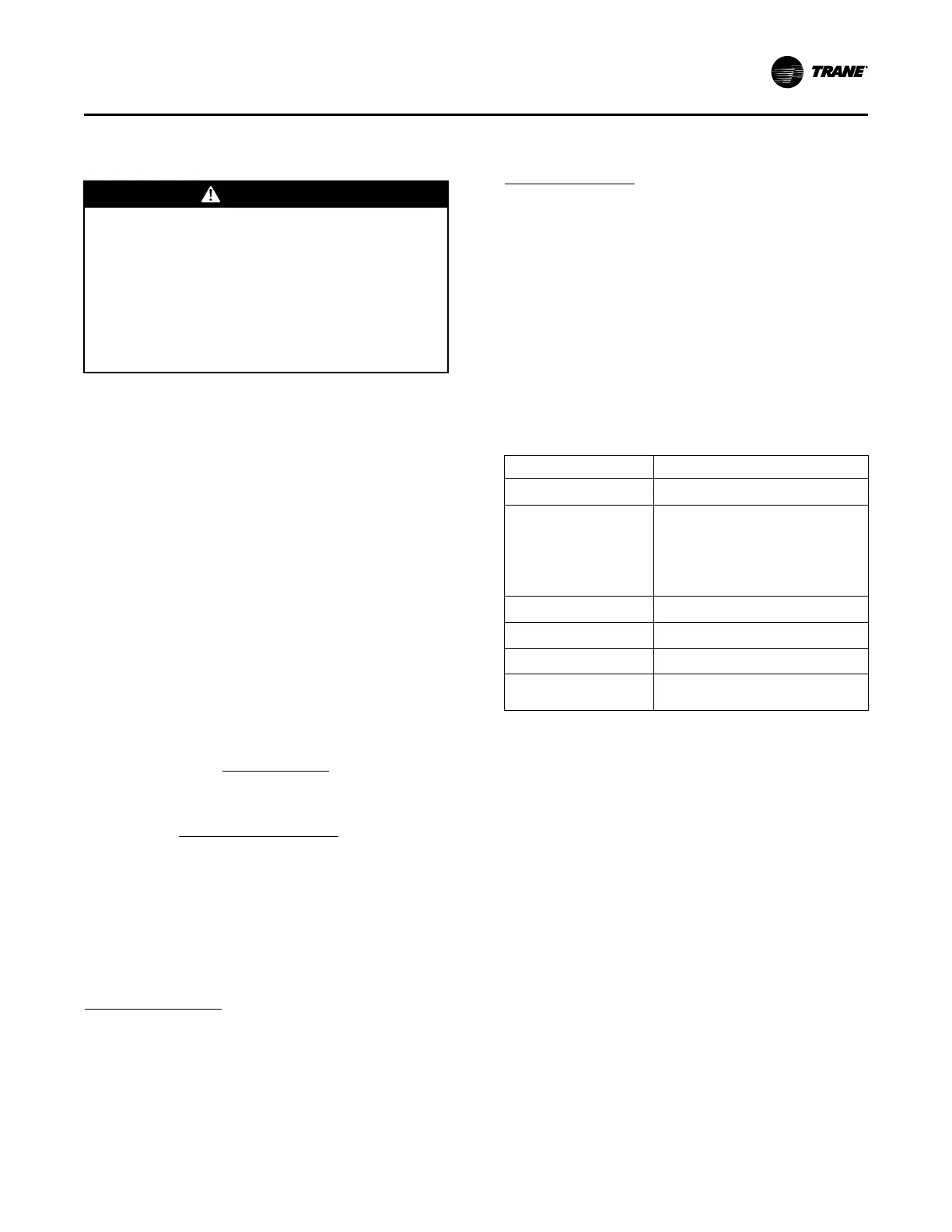

Electrical Cable

Table 3. Technical cable data, size 2/0

Conductor size: 2/0 AWG

Ampacity: 265 Amps per conductor

(a)

Construction: Rope stranded copper conductor,

colored-coded (blue, red, green and

black) connectors on each end.

Insulation is composed of water, acid,

ozone and chemical resistant

thermoplastic rubber compound.

Temperature rating (°F): -49 to 194

Weight (Lbs./100 Ft.): 64

Conductor nominal OD (in.): 0.8200

Cable rating: UL Rated at 2000 volts, C(UL) 600 volts

for continuous use.

(a)

The values listed above are based upon ambient temperature @ 86°F, where

the individual conductor is not installed in raceways or buried (Reference NEC

Code, Table 400.5 (A)(2), 2014 Edition).

Installation - Electrical

Loading...

Loading...