36 RT-SVX25G-EN

Start Up

Economizer Start-Up

Using the Service Test Guide in Table 8, p. 35, momentarily

jump across the Test 1 and Test 2 terminals on LTB1 one-

time to start the Minimum Ventilation Test.

1. Set the minimum position setpoint for the economizer

to the required percentage of minimum ventilation

using the setpoint potentiometer located on the

Economizer Control (ECA).

The economizer will drive to its minimum position

setpoint, exhaust fans (if applicable) may start at

random, and the supply fan will start when the

SERVICE TEST is initiated.

The Exhaust Fan will start anytime the economizer

damper position is equal to or greater than the exhaust

fan setpoint.

2. Verify that the dampers stroked to the minimum

position.

3. Momentarily jump across the Test 1 and Test 2

terminals on LTB one additional time if continuing

from previous component start-up or until the desired

start-up component Test is started.

4. Verify that the dampers stroked to the full open

position.

5. To stop the SERVICE TEST, turn the main power

disconnect switch to the “Off” position or proceed to

the next component start-up procedure. Remove

electro mechanical test mode connections (if

applicable).

Compressor Start-Up

1. Attach a set of service gauges onto the suction and

discharge gauge ports for each circuit. Refer to the

refrigerant circuit illustration in the Service Facts.

Using the Service Test Guide in

Table 8, p. 35, continue

the Service Test start-up procedure for each

compressor circuit.

Momentarily jump across the Test 1 and Test 2

terminals on LTB1 one additional time if continuing

from previous component start-up or until the desired

startup component Test is started.

Scroll Compressors

a. Once each compressor has started, verify that the

rotation is correct. If wired correctly the suction

pressure should drop and the discharge pressure

should rise. If a scroll compressor is rotating

backwards, it will not pump and a loud rattling

sound can be observed.

b. If the electrical phasing is correct, before

condemning a compressor, interchange any two

leads (at the compressor Terminal block) to check

the internal phasing. Refer to the following

illustration for the compressor terminal/phase

identification. Do not allow the compressor to

operate backwards for more than 5 seconds.

Operation for a period of time longer than this will

result in compressor damage. Copeland (Alliance)

will experience failure also. If the compressor runs

backward for an extended period, the motor

winding can overheat and cause the motor winding

thermostat to open.

Note: The Copeland, SSA and SPA scroll compressors for

R-410A units use Trane OIL00094. The correct Oil

for Trane CSHD is Trane OIL00079 or OIL00080.

Compressor types are listed in Table 9, p. 36. The

a

ppropriate oil charge is listed in Table 10, p. 37.

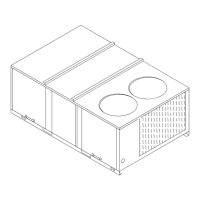

Figure 27. Compressor terminal box

Table 9. Compressor types

Ton n ag e C1 C2

TS* 150 SSA067 SSA054

TH* 150 SSA076 SPA044

TH* 150 Reheat SSA067 SSA067

TS* 180/ 155 CSHD105

SPA050 (SPA054 on 380V/ 60Hz/ 3Ph

units only )

TH* 180 CSHD089 SSA057

TH* 180 Reheat SSA083 SSA083

TS* 210/ 175 CSHD120

SPA044 (SPA054 on 380V/ 60Hz/ 3Ph

units only )

TH* 210 CSHD105 SSA057

TH* 210 Reheat CSHD089 SSA083

TS* 240/ 200 CSHD142 SSA083

TH* 240 CSHD142 SSA083

TH* 240 Reheat CSHD120 CSHD1 20

TS* 300/ 250 CSHD12 0 CSHD1 20

TH* 300 CSHD155 SSA083

Loading...

Loading...