WTK-SVN001-EN

7

Connection Unit

with Brazing Procedure

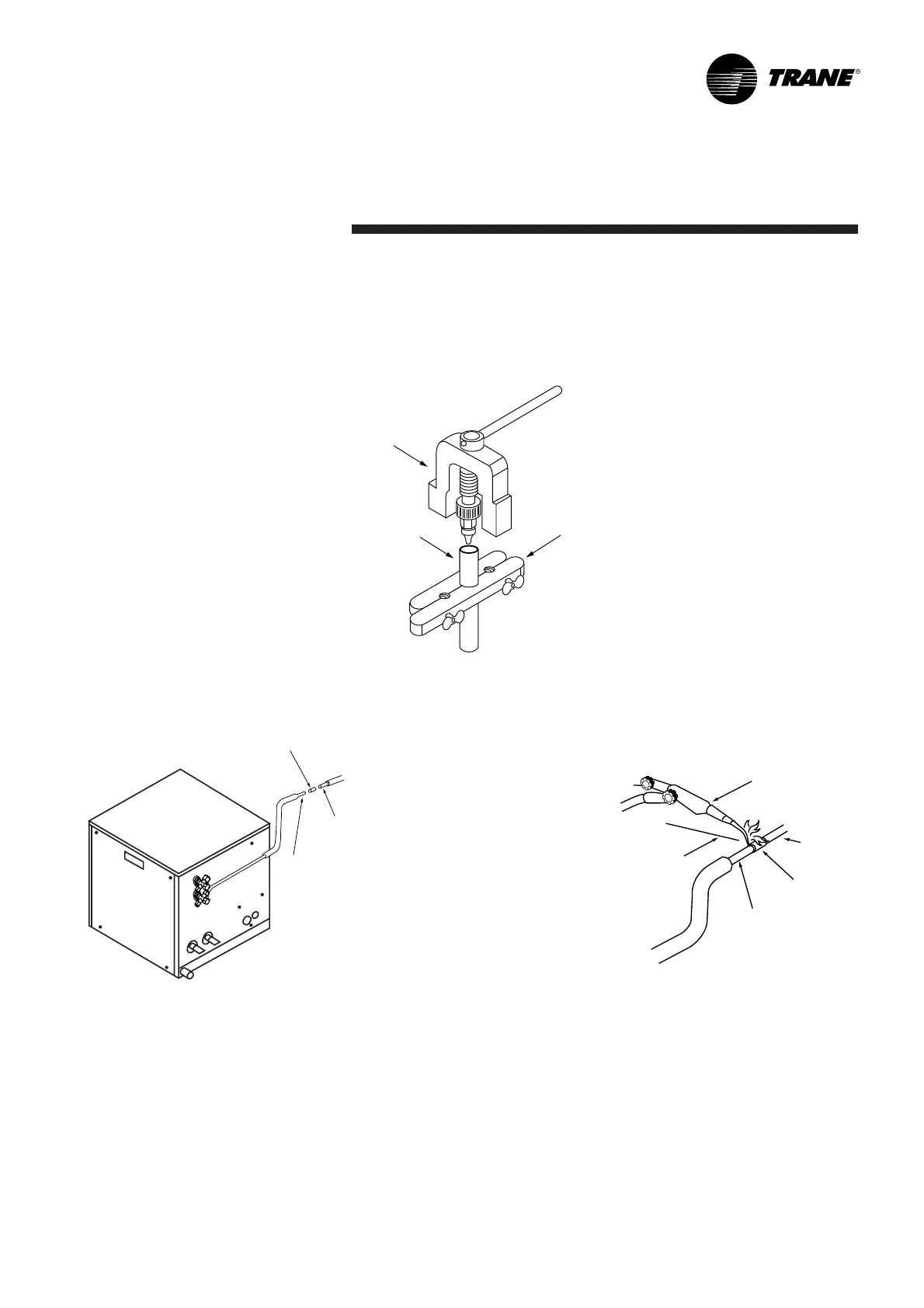

Figure 9

Tube enlarging

tool

Copper

tube

Tube fixing

tool

COMMET 3

Brazing

wire

Brazing head

(torch)

Copper tube from

condensing unit

Tube

connector

(straight)

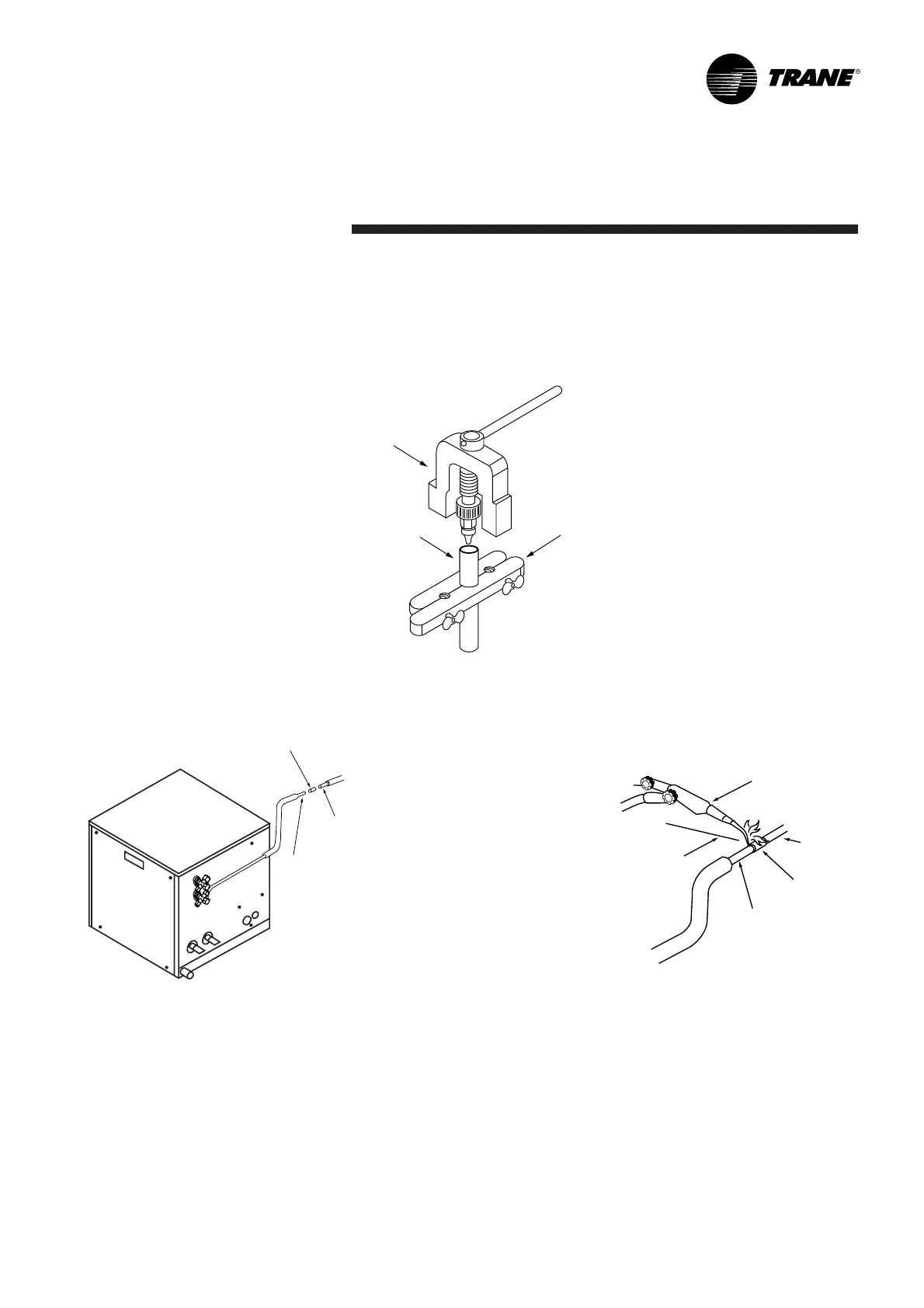

Figure 10

Connection Unit with Brazing

Procedure

1. Cut the copper tube to the require

length with the tube cutter. It is

recommended to cut approximately

20-30 cm longer than the tube

length you estimate and put in the

straight line while cutting.

2. After cutting, remove burrs at the

end of copper tube with a tube

reamer. Hold the end downward

and be sure that no copper scraps

fall into the tube (Figure 2).

3. There are 2 methods to connect

copper tube

- Use tube connector between

copper tube from fan-coil unit and

copper tube from condensing unit

(Figure 8).

Copper tube from

condensing unit

Copper tube from

fan coil unit

Figure 8

Tube connector

(straight)

- Expand copper tube with the tube

enlarging tool (Figure 9).

4. Clean copper tube surfaces

both inside and outside before

connection, expansion, or brazing.

5. Insulate the entire gas line.

6. Do not allow uninsulated liquid line

to come in direct contact with bare

gas line.

7. Precautions should be taken to

avoid heat damage to the pressure

tap valve core during brazing. It is

recommended that a wet rag be

wrapped around the valve body.

8. It is recommended to use braze

shield, soak pad in water and place

over suction and liquid lines to

protect unit finish.

9. To braze the copper tube, before

brazing a copper tube to a solder

coupling or a copper tube to an

expanded tube, do not forget to

keep them tight as shown in

figure 10.

10. Use a dry nitrogen purge and

brazing alloy without flux when

brazing the field line to the copper

factory connection. Flow dry

nitrogen into either valve pressure

tap port, through the tubing and

out the other port while brazing.

11. Braze using accepted good

brazing techniques.

Loading...

Loading...