Installation

26 RT-SVX21K-EN

Horizontal Discharge Conversion

(3 Through 5 Ton Units)

Note: 3 - 5 ton units supply cover to supply opening and

return cover to return opening.

Supplies needed by installer for conversion: 3 oz. tube of

high temperature RTV sealant. (500°F / 260°C: similar to

Dow Corning 736)

Important: Failure to use recommended sealant could

result in unit performance loss.

If a unit is to be converted to a horizontal discharge, the

following conversion must be performed:

1. Remove RETURN and SUPPLY duct covers.

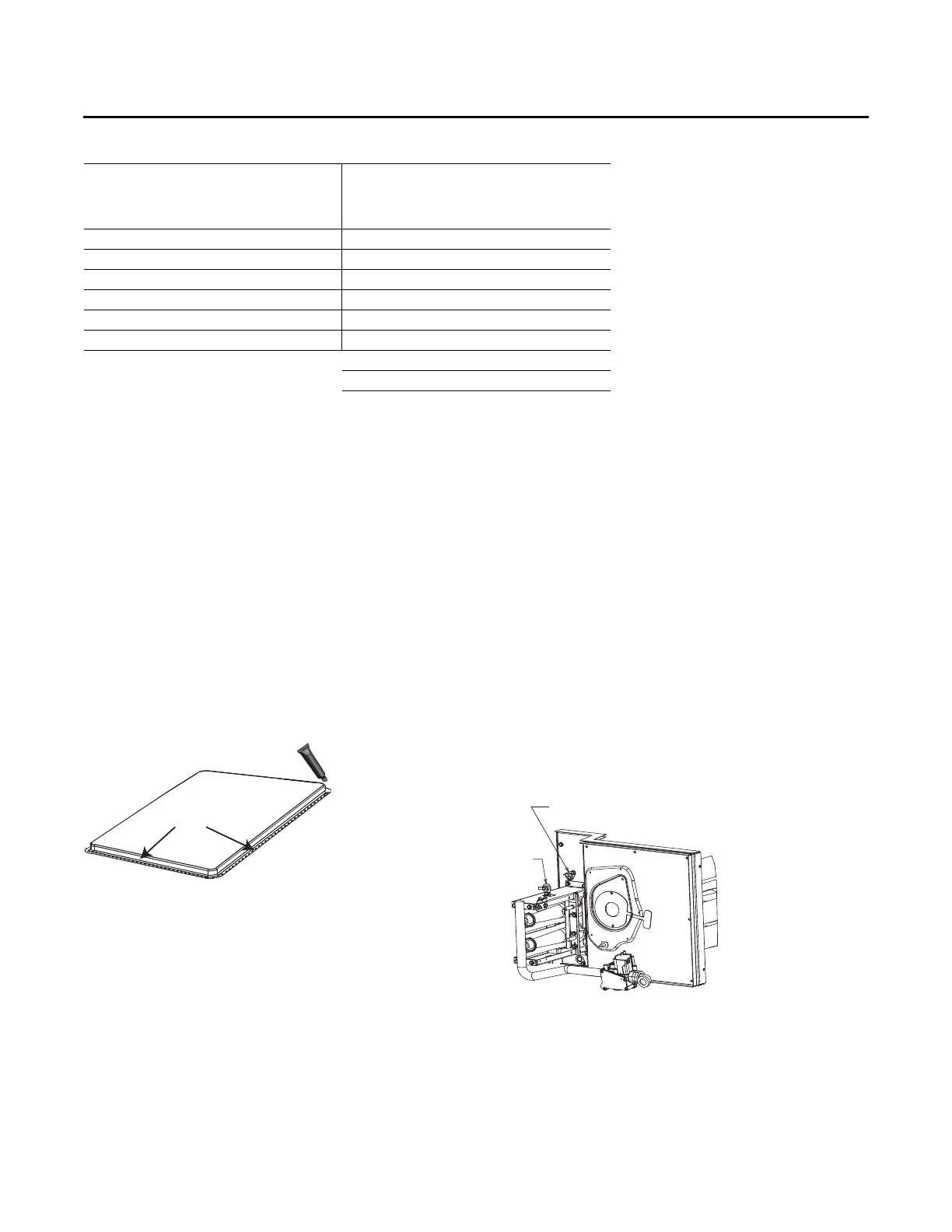

2. Locate supply cover. Apply ¼ in. (6mm.) continuous

bead of 500°F RTV sealant to the flange as shown.

3. Position duct cover as shown, rotate 90 degrees to

allow entrance into supply opening.

4. Slide duct covers into duct openings until inward edge

of duct cover engages with the 2 retaining clips on the

duct flanges. Secure the outward edge of each duct

cover with 2 screws.

5. Slide RETURN DUCT COVER (insulation side up) into

supply opening until inward edge of duct cover

engages with the 2 retaining clips on the duct flange.

Secure outward edge of the duct cover with two

screws.

6. After completing installation of the duct covers for

horizontal discharge, proceed to TCO-1 instructions.

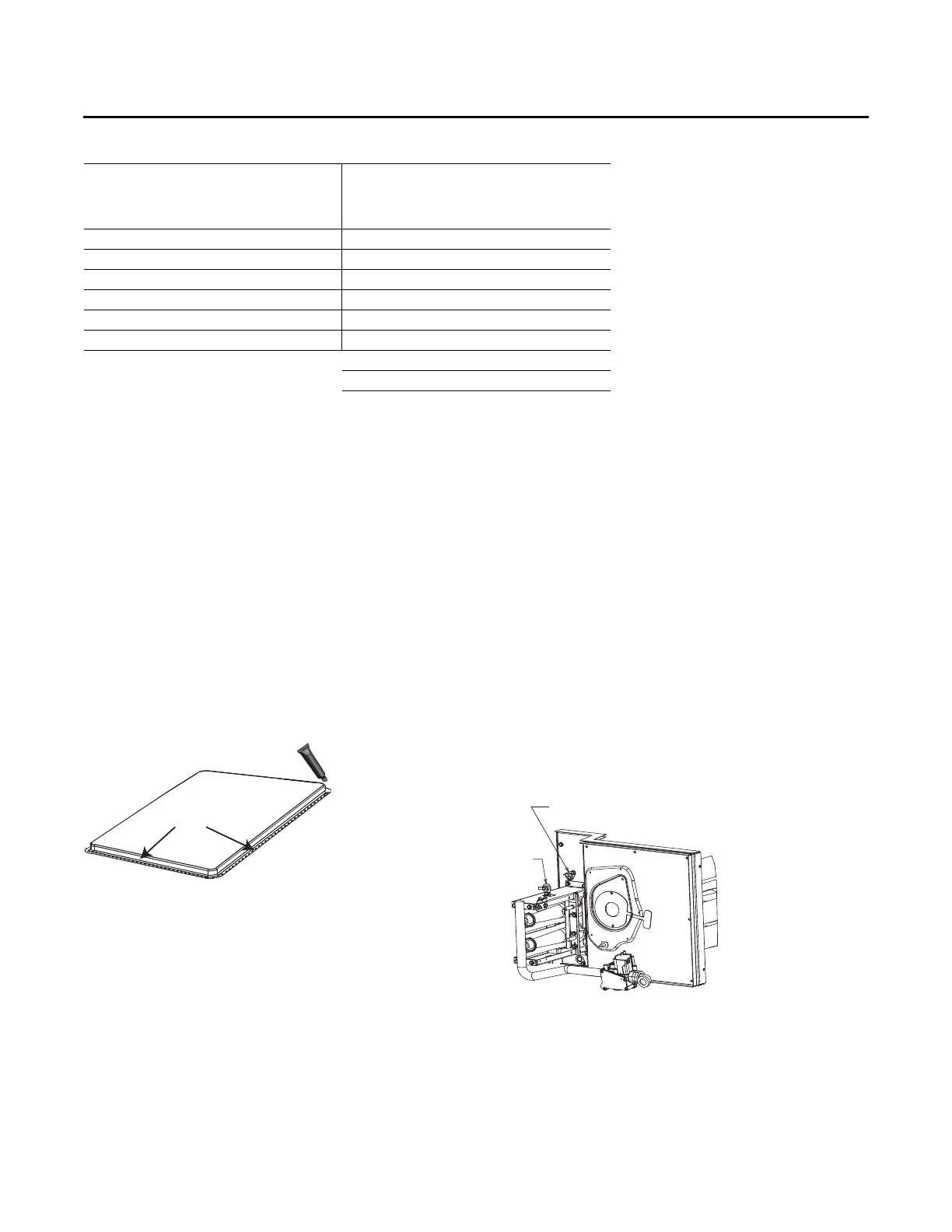

TCO-1 Instructions

If the unit being installed is listed in the following list, the

limit control TCO1 must be replaced with the extra limit

control shipped in the heater compartment. Replace TCO1

following the instructions in steps 1through 3 below. If the

unit being installed does not correspond to any in the

following list, skip steps1 through 3 and go on to next step

in the installation process.

Unit Model Number

YSC036E**(M,Y), YSC036E**(H,Z), YSC048E**(H,Z),

YSC048E**(M,Y) belt drive ID motor, YSC060E**(H,Z)

direct drive ID motor, YHC047E**(L,X), YHC048E/F**(L,X)

direct drive ID motor, YHC060E/F**(L,X) belt drive ID

motor, YHC036E**(M,Y), YHC037E**(M,Y), YHC048E/

F**(M,Y), YHC060E/F**(M,Y) direct drive ID motor,

YHC036E**(H,Z), YHC048E/F**(H,Z) belt drive ID motor,

YHC060E/F**(H,Z).

Unit Model

(Standard

Efficiency)

TCO1 Tripping

Values

Down flow/

Horizontal

Unit Model

(High Efficiency - 15

SEER)

TCO1 Tripping

Values

Down flow/

Horizontal

YSC102F**(L,X) 225F YHC092F**(M,Y) 180F / 200F

YSC102F**(M,Y) 230F YHC092F**(H,Z) 200F

YSC102F**(H,Z) 200F / 260F YHC102E**(L,X) 135F

YSC120F**(L,X) 180F / 200F YHC102E**(M,Y) 135F

YSC120F**(M,Y) 200F YHC102E**(H,Z) 170F

YSC120F**(H,Z) 190F / 260F YHC120E**(L,X) 135F

YHC120E**(M,Y) 170F

YHC120E**(H,Z) 145F / 190F

Table 3. TC01 tripping values (continued)

Figure 26. Duct cover

Figure 27. TCO1 location (YSC036E-YSC060E, YHC036E,

YHC037E)

FLAMEFLAME

ROLLOUTROLLOUT

LIMIT LIMIT

LOCATION OF TCO1 LIMIT LOCATION OF TCO1 LIMIT

FOR THE Y(S/H)C036E, YHC037E, FOR THE Y(S/H)C036E, YHC037E,

YSC048E, AND YSC060E UNITSYSC048E, AND YSC060E UNITS

Loading...

Loading...