-12-

(3) How to Operate

a. Turn the power switch ON. The heating element reaches the working temperature at

approximately 3 minute.

b. Place a package on the table top (The package must cover the Slide Table).

c. Properly adjust the strap tension according to various package.

d. Place the strap around the package to be strapped and insert the strap into the strapping

head until it stops.

e. The strapping and welding sequence should complete.

f. At end of strapping sequence the strap end is fed automatically, and Feeding Length

Knob is to adjust the strap length.

7. Adjustments

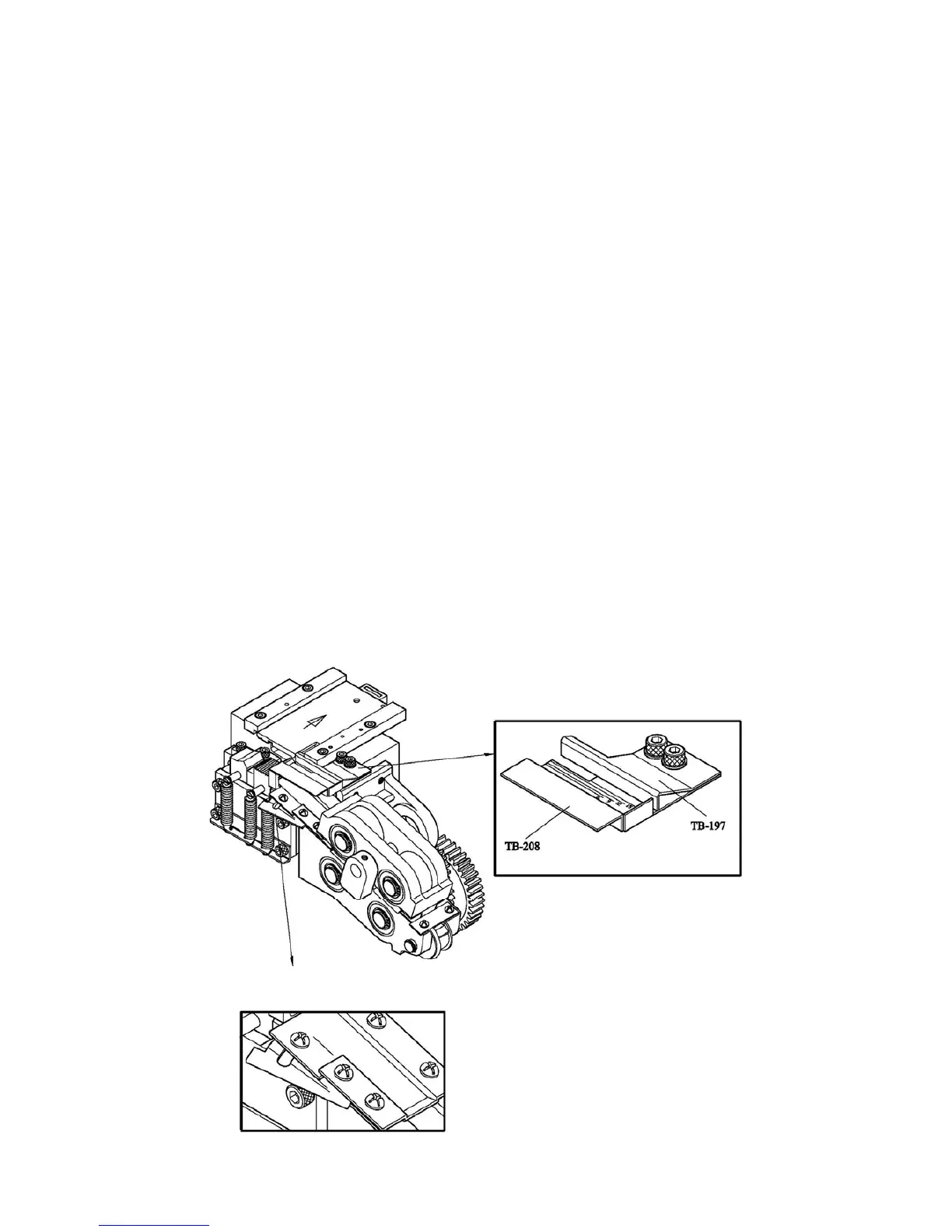

(1) Strap Width

Adjustment for strap in different width can be done with only one Philips recess

screw driver and a hex spanner. The adjustment must be made in two places, A (Strap

Outlet), B (Strap Inlet) as shown below.

For A, the width of band guide should be at 12.5mm to 13.0mm when using 9mm and

12mm strap and the width of band guide should be at 15.5mm to 16mm when using 15mm

strap.

For B, The width of band guide should be wider by 0.5mm to 1.0mm than the actual

strap width.

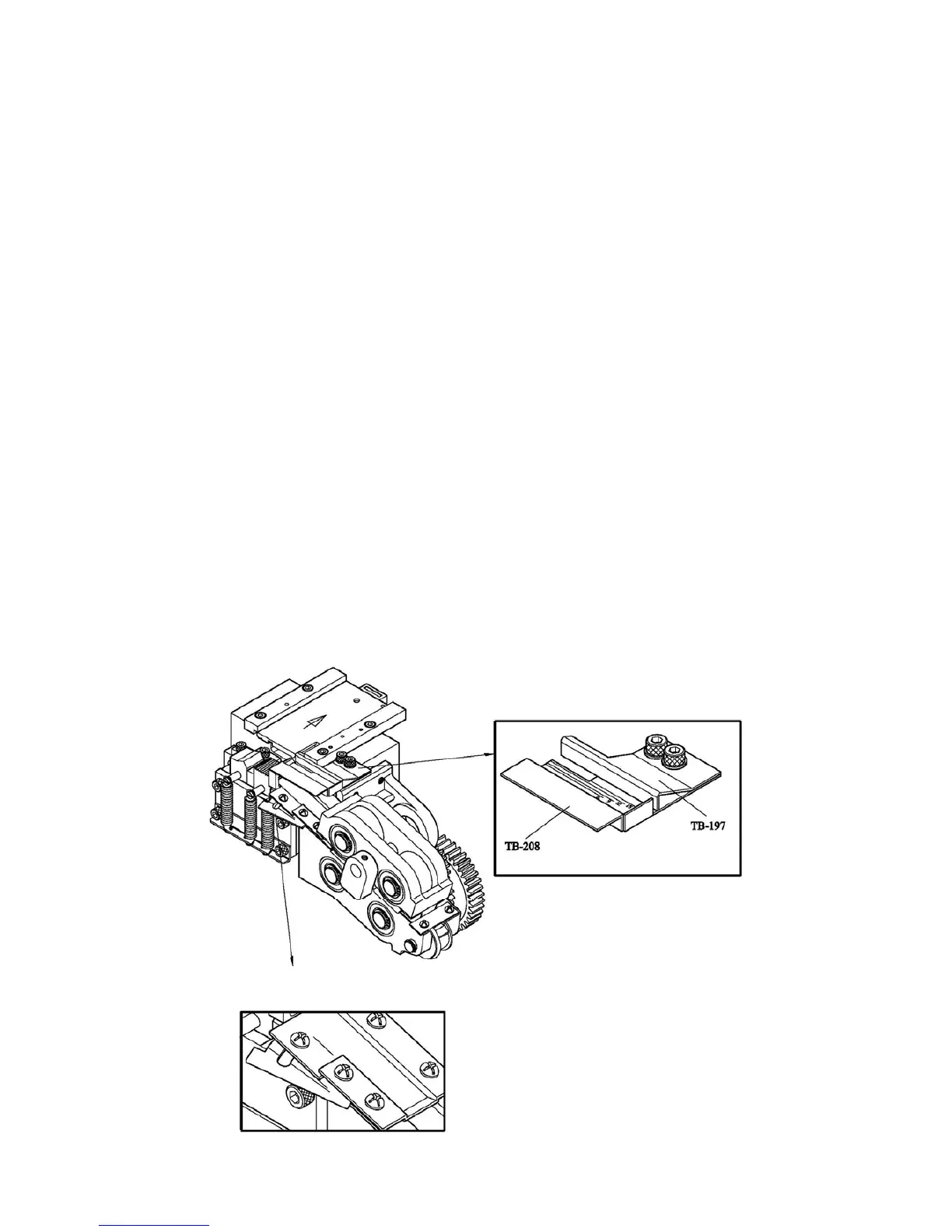

The adjustment is made with the

guide located on the top of the

table. Make both adjustments

by loosening two screws and

applying the strap which is to be

used.

Fig. A Strap Outlet

Fig. B Strap Outlet

Loading...

Loading...