7

THE FIRST TANK OF FUEL

Once the engine is started, drive the boat slowly at first to warm

the engine. Ease in and out of the throttle slowly. Vary your

speed between low and medium throttle until about half of the

first tank of fuel is used. Do not run at full speed during the first

tank of fuel. Do not rev the engine when the boat is out of the

water. High, no-load RPMs can damage the engine.

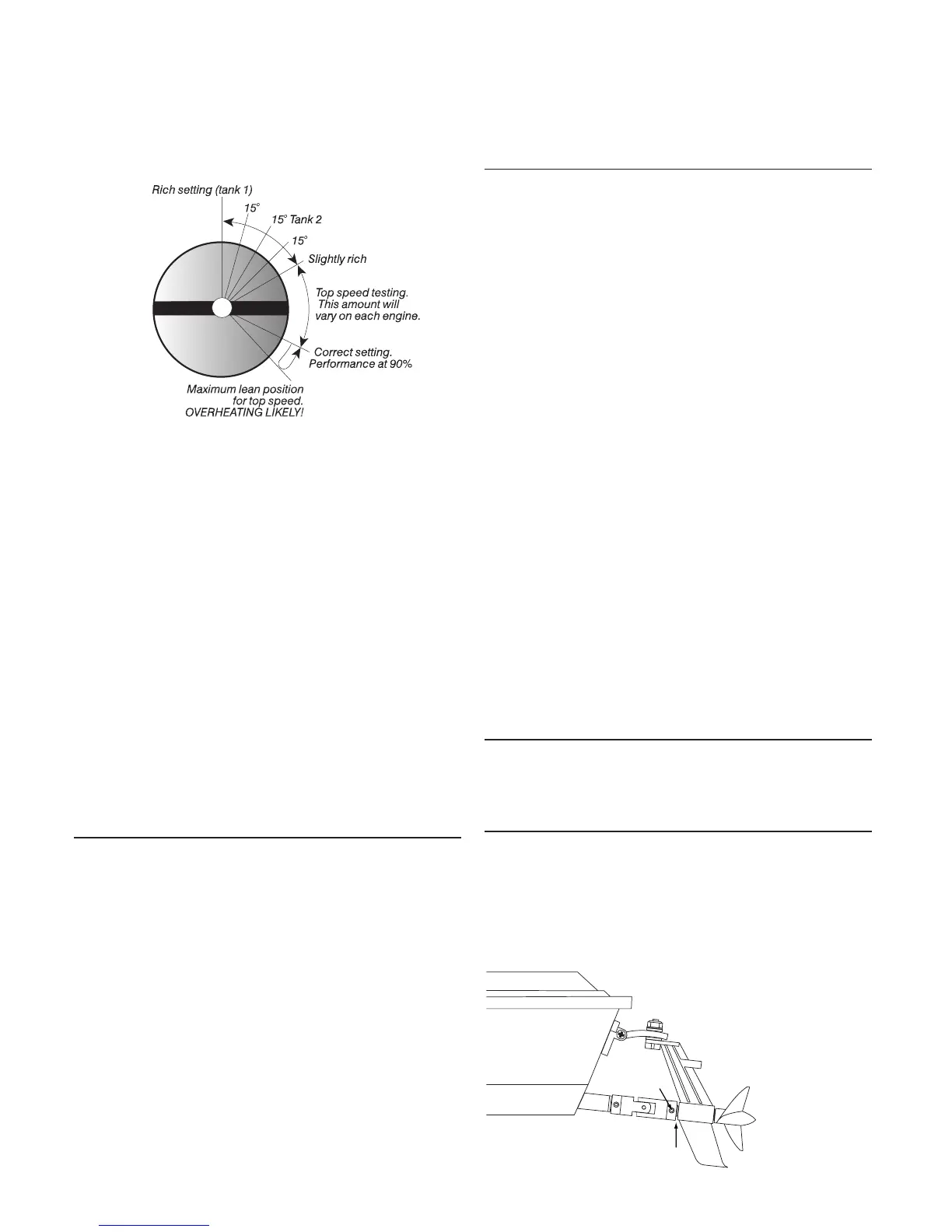

The baseline setting of the high-speed mixture screw will vary

slightly with each engine. To know if your engine is set correctly for

break in, look for the following performance characteristics (on a

warm engine):

• The engine will accelerate sluggishly from a standing start and

may even try to stall if the throttle is applied too quickly.

• Blue-white smoke will be emitted from the exhaust.

• When the model is accelerating at full throttle, the engine will

never “clean out.” When an engine “cleans out”, the speed and

rpms will increase suddenly and dramatically, as if the engine

has gone into “second gear.” Also the amount of smoke emitted

from the exhaust will decrease. “Cleaning out” is a desirable

characteristic once the engine is broken-in; however, during the

first two tanks, it should be avoided.

Halfway through the first tank of fuel, bring the boat in and lean

the fuel mixture by turning the high speed needle clockwise 15

0

.

As the engine reaches normal operating temperature, it will speed

up and performance will improve. This occurs because the fuel

mixture is becoming leaner with the increased temperature. You

may need to richen the fuel mixture very slightly so that the engine

continues to run as described above.

When the first tank is used, bring the model in, shut off the engine,

and allow it to cool for 7-10 minutes before continuing.

THE SECOND TANK OF FUEL

Tu rn the high-speed mixture screw clockwise 15

0

and run through

half of the second tank of fuel.

Halfway through the second tank, bring the model in and lean

the fuel mixture another 15

0

(see illustration).

During break in, watch closely for any signs of overheating.

These include:

• Steam or smoke emanating from the engine surfaces

• Lagging during acceleration (as if running out of fuel)

• Popping or clattering sound when decelerating (detonation)

• Idle speed will surge or possibly diminish to the point of stalling.

IF THE ENGINE STALLS WHILE YOU ARE DRIVING, BECAUSE

OF AN OVERHEATING CONDITION, SEVERE DAMAGE HAS

PROBABLY ALREADY OCCURRED. OVERHEATING IS

CAUSED BY THE FOLLOWING OPERATIONAL ERRORS:

• HIGH SPEED MIXTURE IS SET TOO LEAN

• EXCESSIVE NITRO IN THE FUEL

• INCORRECT OIL CONTENT IN THE FUEL

• POOR QUALITY FUEL

• EXCESSIVE LOADS PLACED UPON THE ENGINE (caused by

a bound drivetrain)

YOUR ENGINE WILL BE SHORT-LIVED IF ANY OF THE ABOVE

CONDITIONS ARE ALLOWED TO PERSIST.

TUNING FOR POWER

After the second tank of fuel, the internal engine parts should

be broken-in.You can now begin adjusting the fuel mixture to max-

imize performance for your normal driving needs.

The engine should never be run at more than 90-95% of its

maximum performance capacity. As you continue to lean the fuel

mixture, the engine will run faster, up to a point. When the engine

is set too lean, it will seem to run strong at first, but will bog, hesi-

tate, or stall when running at speed. The engine will also rapidly

overheat when the setting is too lean.

At the optimum setting, the engine will have a strong-sounding,

high-pitched whine at full speed; and there will be a thin trail of

whitish smoke emitted from the exhaust. If there is no smoke, the

fuel mixture must be richened to ensure that the engine is getting

enough oil/fuel for adequate lubrication.

Find an area that will allow the engine to run at full throttle. Run

the model two or three passes at full throttle and note the top

speed and acceleration. Turn the high-speed mixture screw clock-

wise 15

0

and retest the model, again noting the performance.

Continue to lean the mixture and retest the model until the Nitro

Vee bogs and starves for fuel at full throttle. When this occurs,

reduce the throttle immediately to medium speed and the boat

should regain its speed. Retrieve the boat, turn the high-speed

mixture screw counter-clockwise (richer), and re-test. Continue to

richen the mixture until the boat no longer hesitates and stalls at

full throttle. At that point, turn the mixture screw counterclockwise

10 to 15

0

. This is the optimum setting that the engine should be

run.

If the boat takes an excessive amount of time to come on plane

but full-throttle (top speed) performance is good, the fuel mixture

might need to be slightly leaner. (Note: A damaged prop will also

cause this same symptom. Check it before leaning the mixture.)

SETTING THE IDLE SPEED

The idle speed may be set too high now that the engine mixture is

tuned. Turn the idle screw out (counter-clockwise) until the engine

will idle slowly and the propeller is not spinning.

ADJUSTMENTS

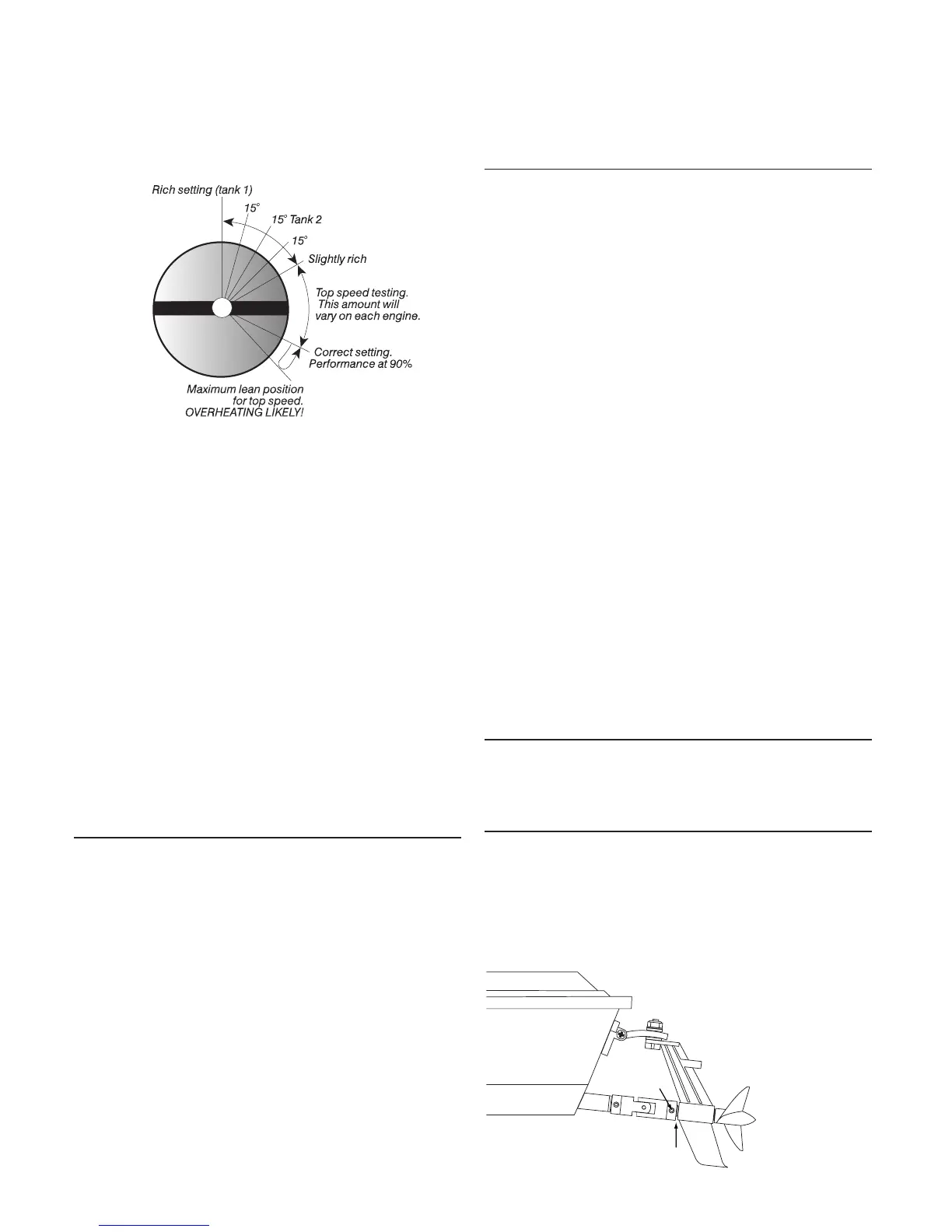

• ADJUSTING THE OUTDRIVE SHAFT END PLAY

There should be a slight amount of shaft endplay in the out-

drive housing. To adjust the endplay loosen the grubscrew on the

U-joint yoke (see drawing). Pull the propeller shaft until there is

no more than 1mm of distance at arrow 2 in the drawing.

Retighten the grub screw.

Loading...

Loading...