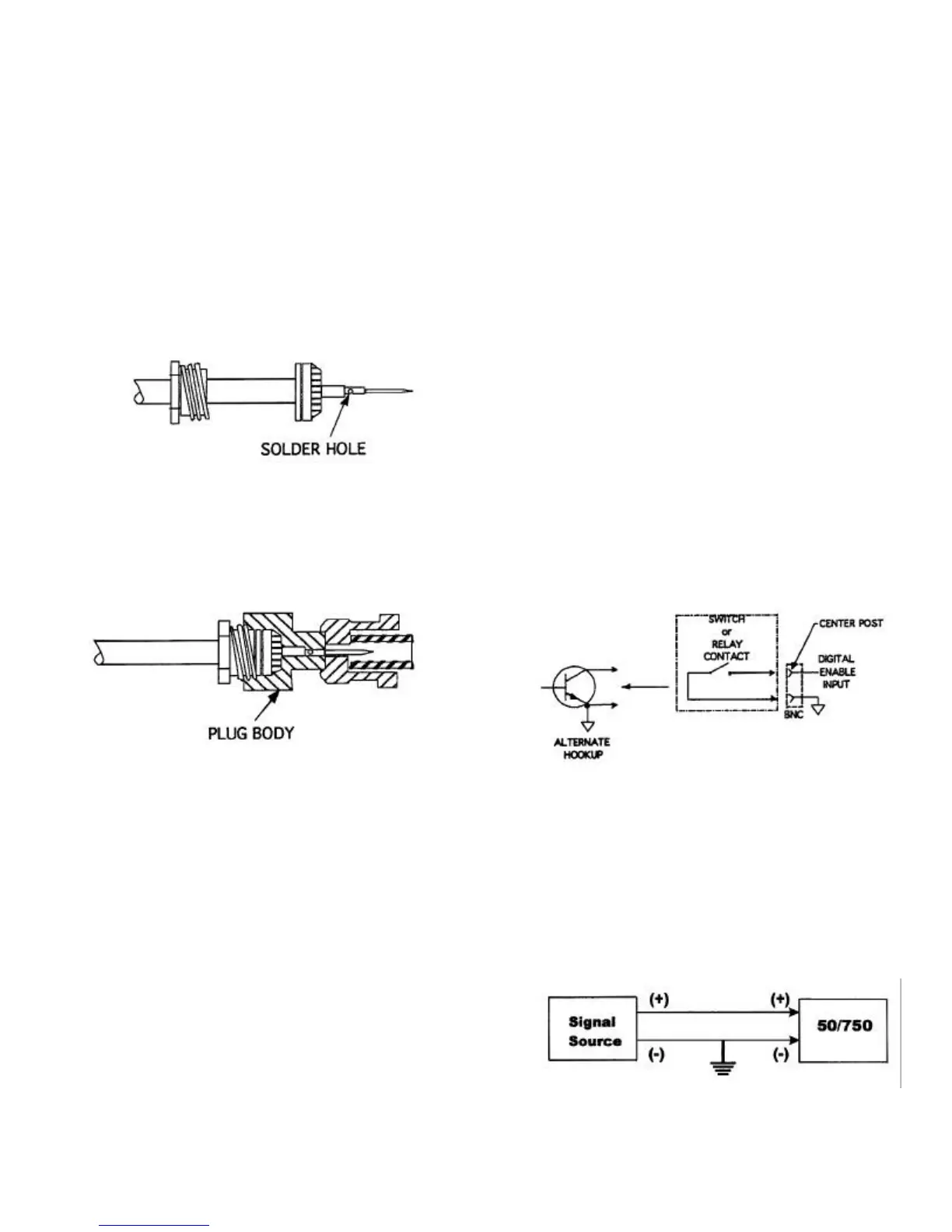

4. Solder the contact onto the conductor

through the solder hole. The contact

should butt flush against the dielectric.

Remove excess solder from outside of

the contact.

CAUTION: Avoid applying excess heat

to the contact. This will cause the

dielectric to swell and interfere with the

connector body.

5. Push the contact assembly into the con-

nector body. Screw the nut into the

body with a wrench until tight. Do not

rotate the connector body on the cable

assembly to tighten.

This completes the high voltage connector/

cable assembly procedure.

LOAD CONNECTIONS

Load connections should be made as short

and direct as possible.

1. Connect the center conductor of the

high-voltage cable to the “hot” side of

the load.

2. Return the low side of the load to the

shield of the coaxial cable or to the

green, five-way binding post on the rear

panel of the amplifier.

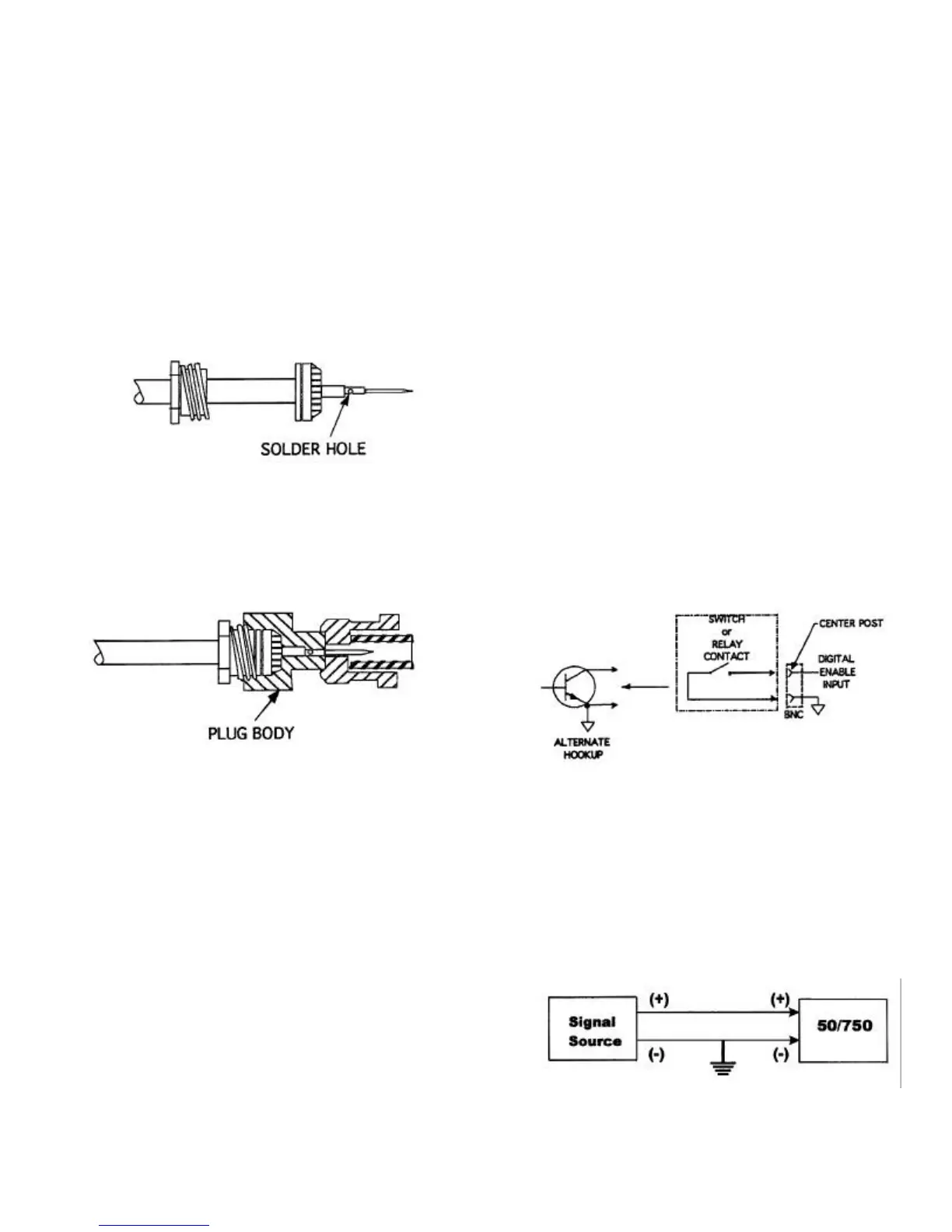

DIGITAL ENABLE CONNECTION

The DIGITAL ENABLE connection is made

at the DIGITAL ENABLE BNC connector on

the front panel of the POWER SUPPLY

module. To control the 50/750 from a

remote device, connect this input to ground

through a switch or relay contact, or connect

it to the output of a controlling device such

as an open collector transistor or TTL gate

that has a current sinking capability of

approximately 2 mA. When contact is made

from the center post to ground (or the BNC

connector shield), both channels are

enabled. When contact is broken, the high-

voltage rails to both channels are disabled.

When a remote enable/disable function is

not required, connect the cap over the

DIGITAL ENABLE receptacle. This shorts

the DIGITAL ENABLE input and allows the

50/750 to operate.

INPUT CONNECTIONS

To prevent noise pickup, the ground refer-

ence for the input signal must be connected

to the input BNC connector shield. See

diagram below.

Loading...

Loading...