-25-

CRT MK2

bearing is acting as the guide.

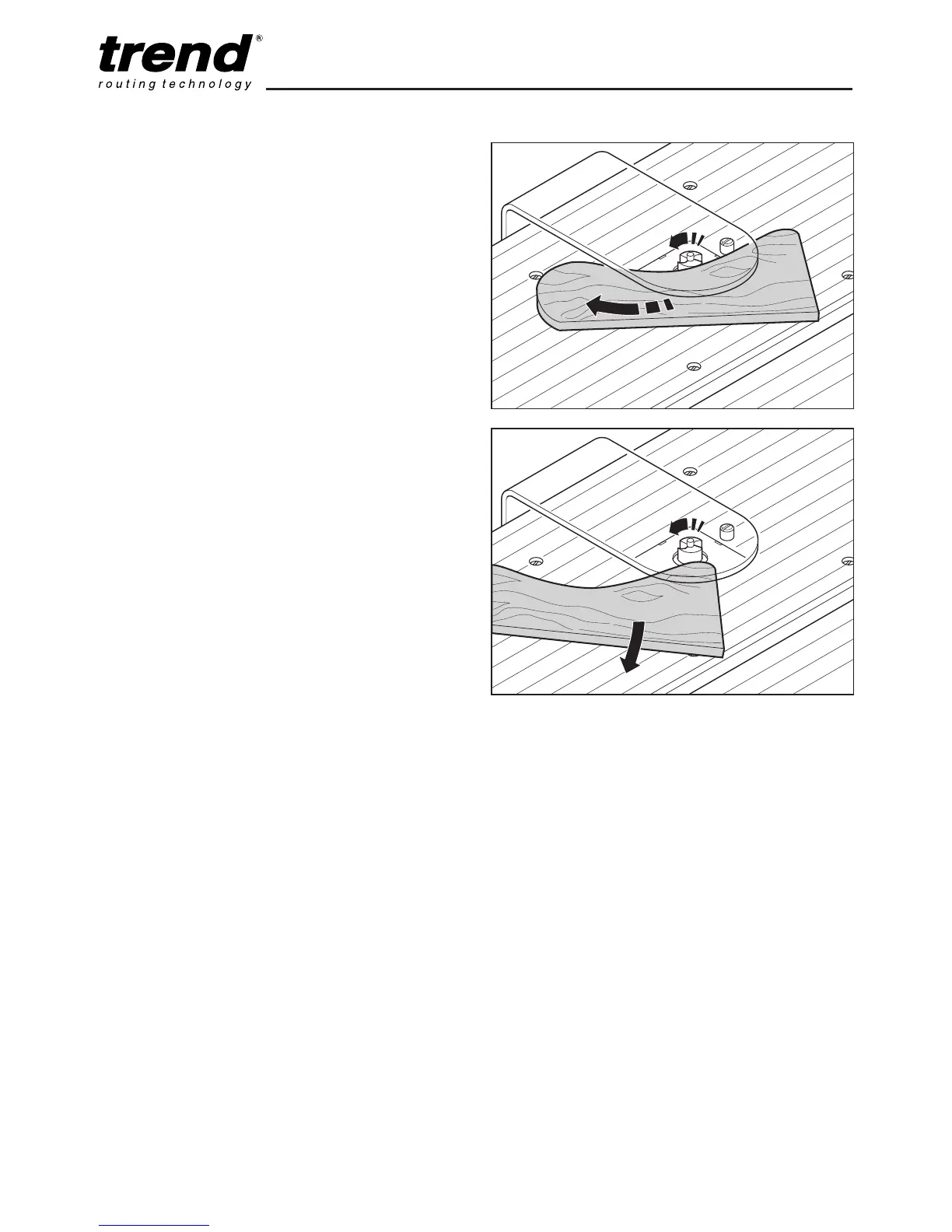

■ Progressively feed the workpiece anti-

clockwise around the shape of the

template ensuring that the ball bearing

always stays in contact with the

workpiece.

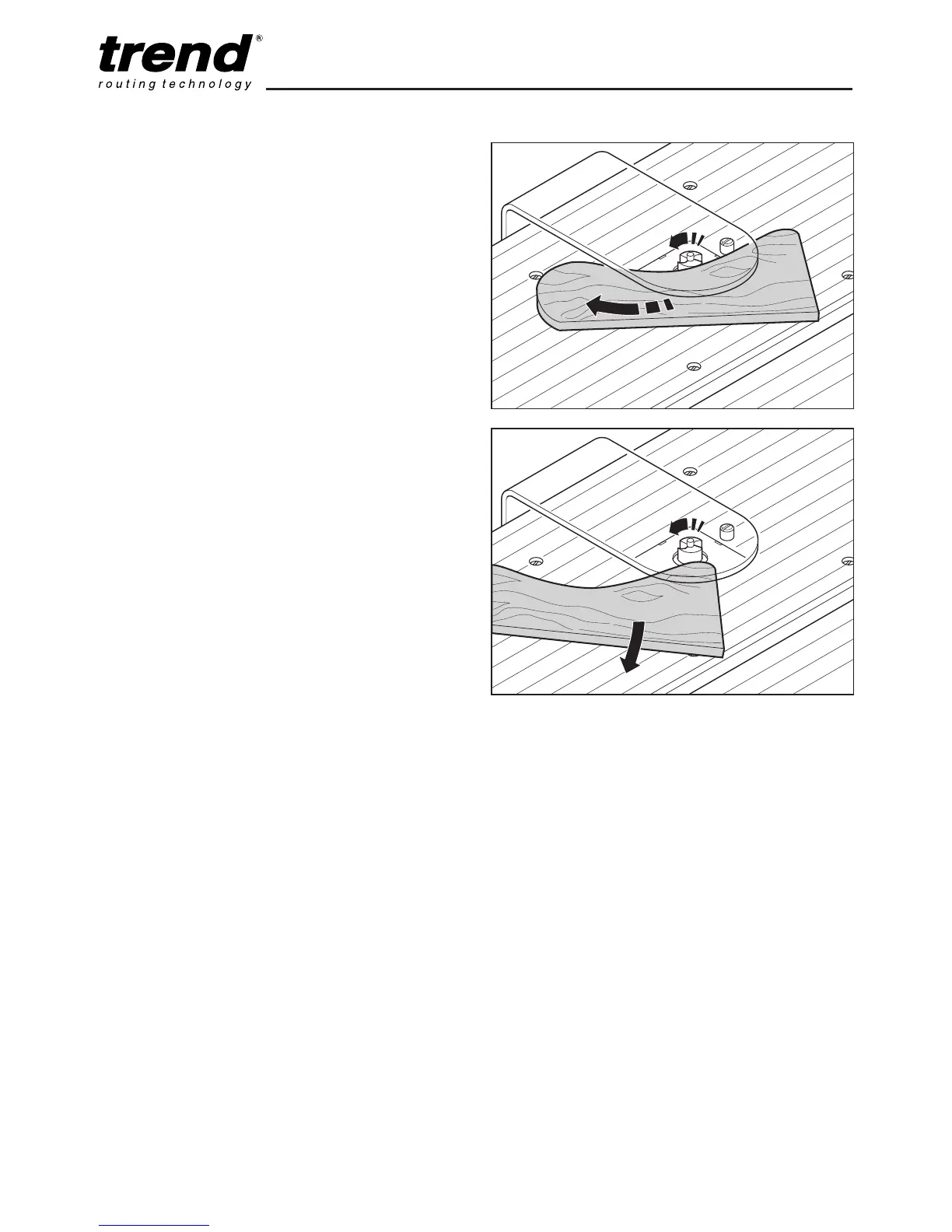

■ When the complete edge of the

workpiece has been machined, slide it

away from the cutter.

■ If you are unfamiliar with the above

procedure then the technique should be

practised before switching on the router.

Helpful Advice

■ Always keep the workpiece moving in a

precise steady movement to prevent the

workpiece from burning.

■ Never let go of the workpiece. Always

keep an even pressure of the workpiece

against the bearing. Do not use too

much pressure.

■ If you wish to stop routing halfway

through the operation. Simply slide the

workpiece away from the cutter before

switching off the router.

■ If the workpiece inadvertently comes

away from the ball-bearing and so does

not complete the cut correctly, do not

stop. Complete the operation and

repeat the procedure for the edge

concerned.

■ It is usually advisable to repeat the

operation in order to improve the finish

of the workpiece.

■ Keeps hands away from the cutter, even

if the guard is fitted, in order to give a

good safety margin.

■ If natural woods are used, consideration

should be given to break-out of short

grain which will effect your decision as to

where to start the routing operation in

order to prevent it.

Loading...

Loading...