Model 301SP Tube Squaring Machine

92-0579 Rev. 190612 19

8. CUTTING SPEEDS AND FEEDS

8.1 Cutting Speeds

8.2 Basic Feed Recommendations

Use very light feed for initial facing or until a continuous cut is established. This is

veryimportantforlongertoolbitlifewhencuttingthroughamecutorout-of-round

pipe ends.

Useadequatefeed,.003”to.006”(.08mmto.15mm)perrevolutionthereafter,to

establish a continuous chip cut. If the feed is too light, only light stringer chips will

be removed. If the feed is too heavy, the drive will start to overload and the chip will

start to have a rough or torn appearance.

Stainless steel, which work hardens, must be worked with a heavy enough feed

tostayundertheworkhardenedsurface(.003”to.006”or.08mmto.15mmfeed)

Never allow the tool bit to burnish the surface.

Reduced feeds and speeds will normally minimize chatter problems.

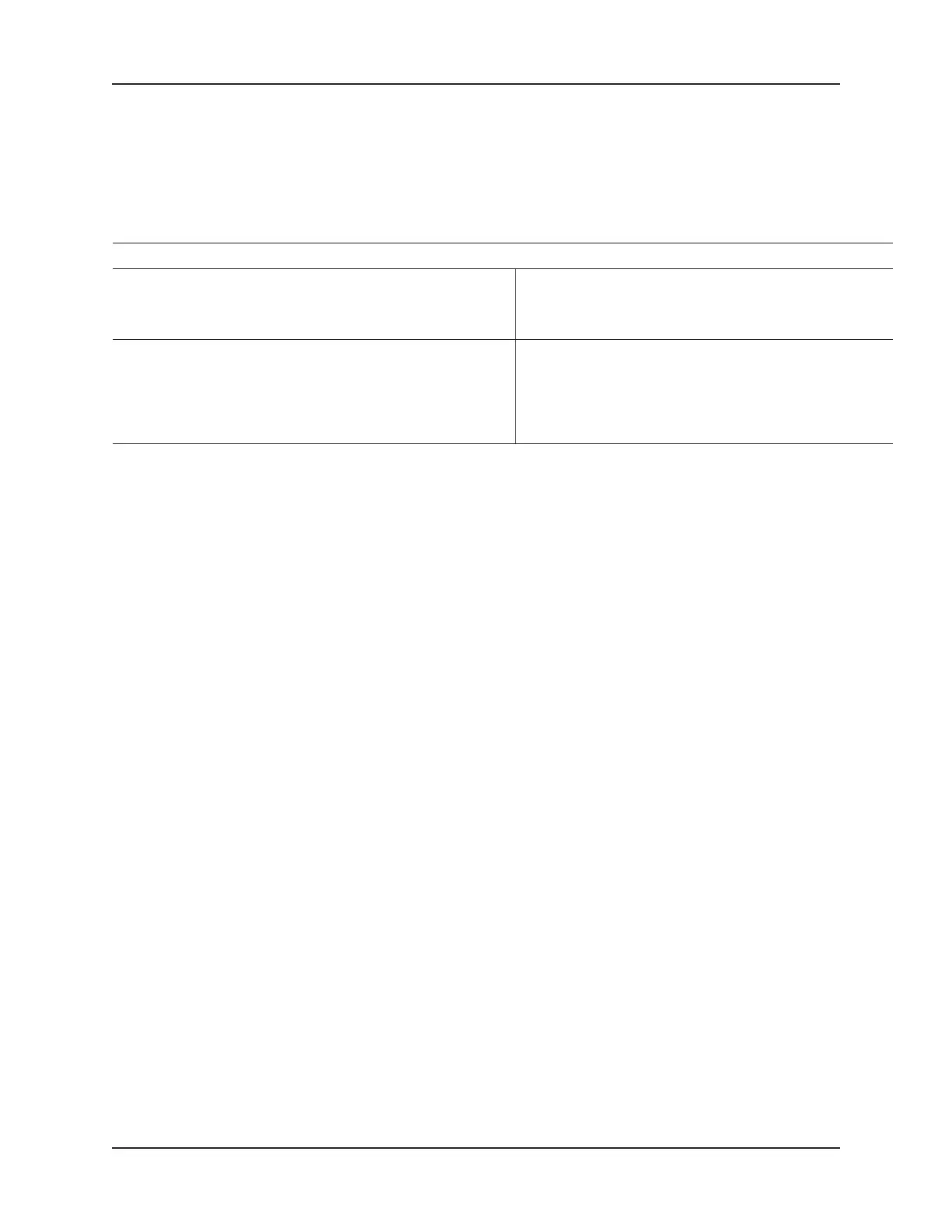

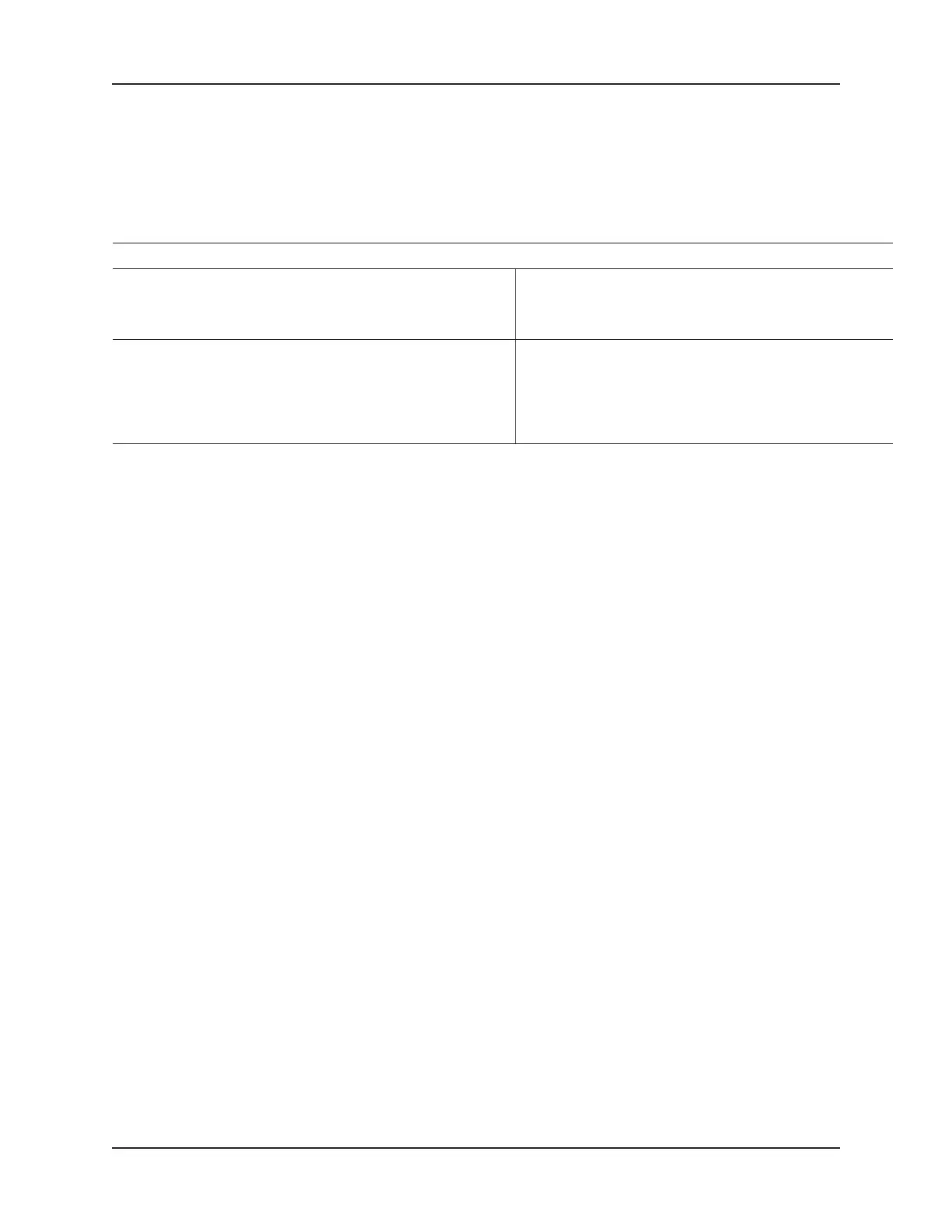

CUTTING SPEEDS FOR TUBE SQUARING

Outside Diameter of the Pipe or Tube

RPM

Range

Time

per Head

Revolution

.25" 6.4 mm 30 to 60 1 to 2 seconds

.50" 12.7 mm 20 to 40 1.5 to 3 seconds

.75" 19.1 mm 15 to 30 2 to 4 seconds

1.00" 25.4 mm 15 to 25 2.4 to 4 seconds

Loading...

Loading...