PDx-170-57-E / TMCM-170 Hardware Manual (V1.10 / 2011-NOV-24) 6

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

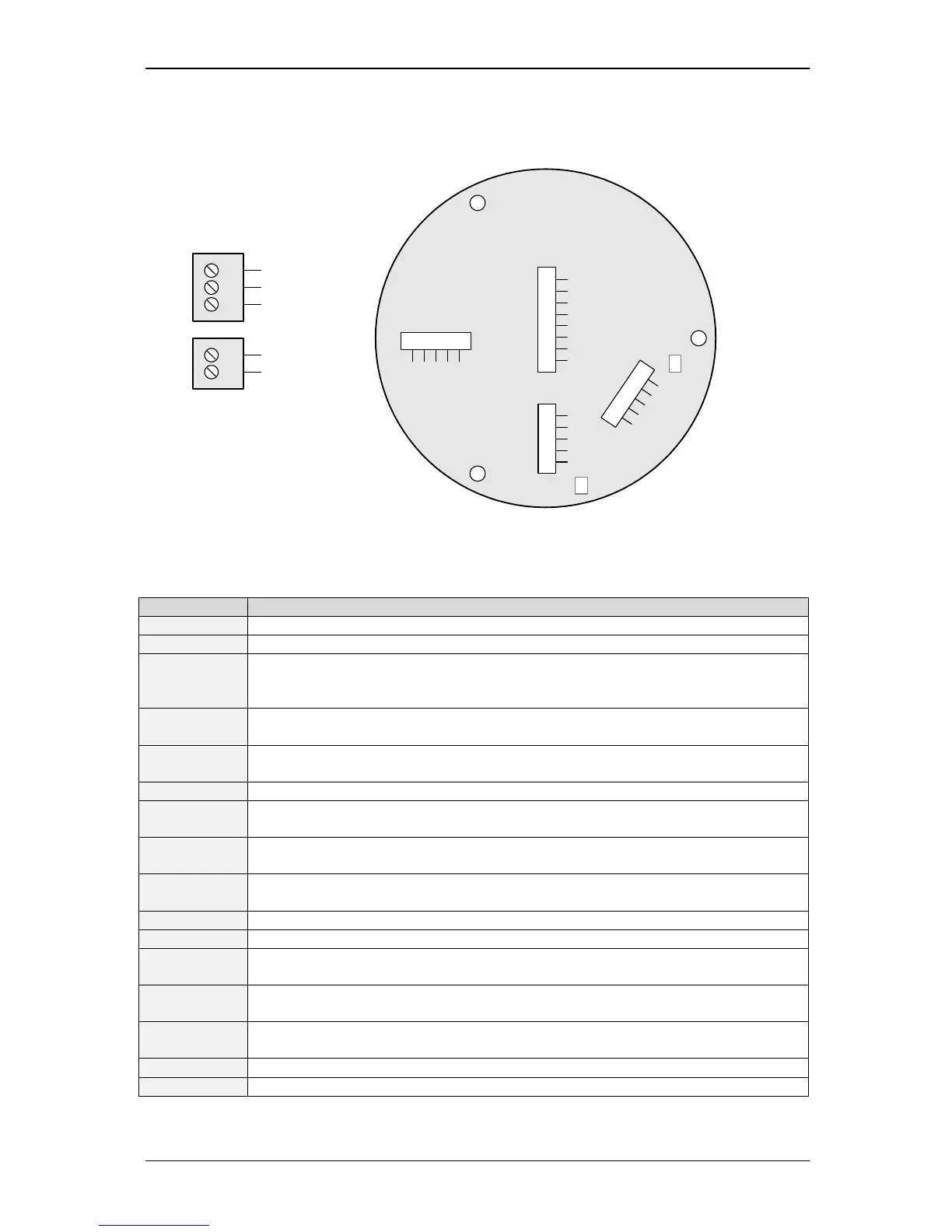

4 Electrical and mechanical description

4.1 Pinning

Connectors shown as top view

3

2

1

W

V

U

Motor / power supply

connector on bottom PCB

Hall

sensors

1.5mm

conn.

1

2

3

4

5

+5V

GND

H1

H2

H3

Inter-

face

5

4

3

2

1

RS485- / TXD

RS485+ / RXD

GND

CANL

CANH

Encoder

5

4

3

2

1

CHB

CHA

CHN/Null

GND

+5V

I/O

8

7

6

5

4

+5V

CUR LED

GND

OVT LED

DIRIN

3

2

1 AIN

N.C.

/STOP

2

1

GND

VS

RS485 Term

CAN Term

Analog input: Can measure 0 - 10V signal.

5V TTL input. Not used in current firmware releases

Reference Switch / Emergency stop. Tie this pin to GND to stop the motor or to clear

the position counter. Function / polarity depends on Software setting.

(5V TTL input with integrated 10K pull-up resistor to 5V)

5V TTL output: Toggling with 3Hz when temperature pre-warning threshold is

exceeded, high when module shut down due to overtemperature.

5V TTL output: High, when module goes into current limiting mode or into

overvoltage switch off. Toggling with 3Hz on undervoltage condition.

5V supply for motor hall sensors and as reference for external purpose

Power GND / GND reference

GND is also connected to the mounting holes on the bottom PCB

RXD signal of module for RS232 communication (RS232 version)

Non-inverting RS485 signal (RS485 version)

TXD signal of module for RS232 communication (RS232 version)

Inverting RS485 signal (RS485 version)

Encoder null channel (optional use)

(5V TTL input with integrated pull-up resistor to 5V)

Incremental encoder channel A / channel B

(5V TTL input with integrated pull-up resistor to 5V)

Hall sensor signals

(5V TTL input with integrated pull-up resistor to 5V)

Positive power supply voltage (reverse polarity protected)

Leave all other pins unconnected!

Loading...

Loading...