13

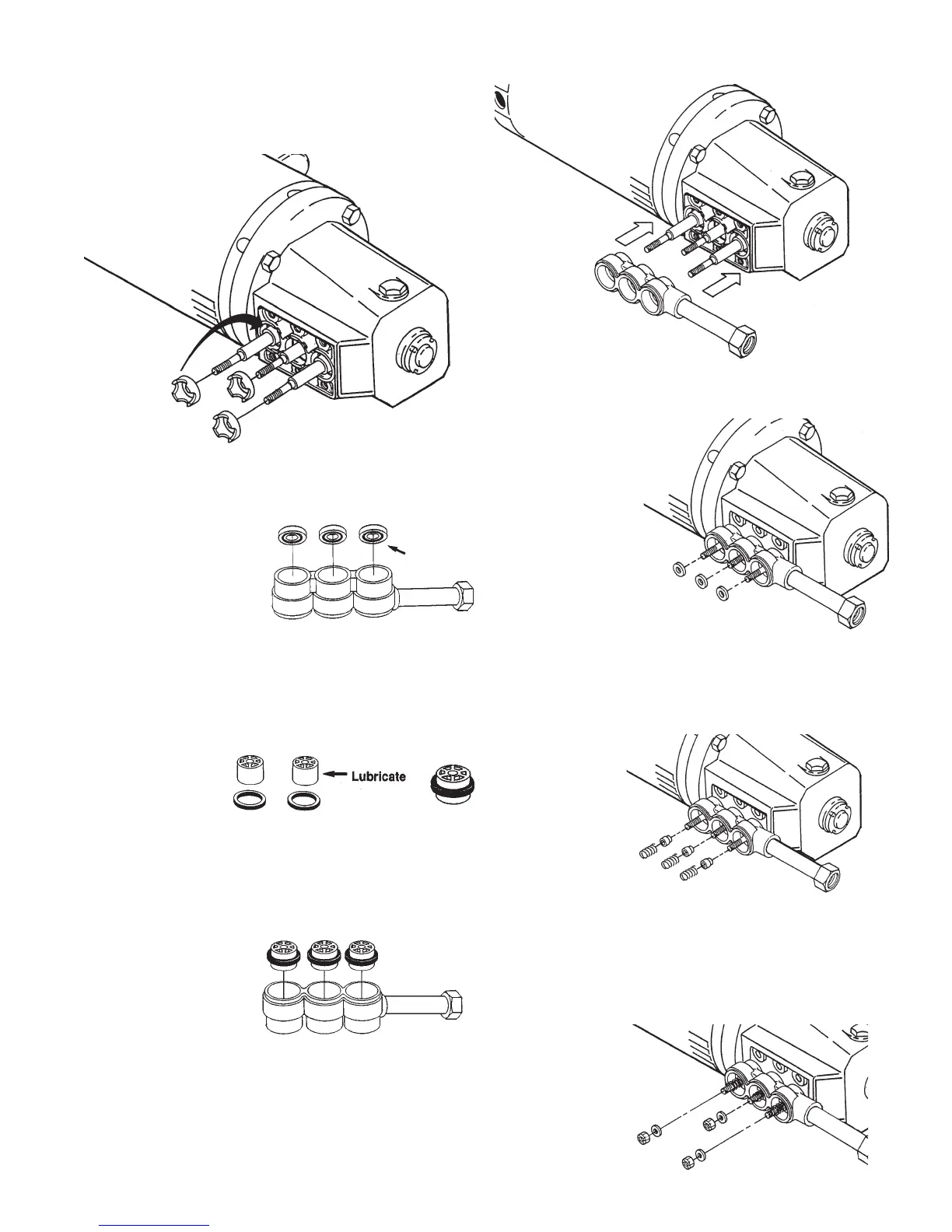

REASSEMBY OF THE SEAL ASSEMBLY

1. Examine seal retainers and replace if worn

or damaged. Install on plunger rod and press

into crankcase with tabs out. (Figure A)

2. Place inlet manifold on work surface with

small I.D. ports up. (Figure B)

3. Lubricate new low

pressure seal and

press into position

in the manifold

chambers with

garter spring

down. (Figure B)

4. Carefully examine plungers for scoring or

cracks and replace if worn. Next lubricate ce-

ramic plungers and new high pressure seals.

Place the

deeper

recessed

hole of the

plunger into

the metal back side of the seal and slide

seal to the middle of the plunger. (Figure C)

5. Place inlet manifold on work surface with

larger I.D. ports up. Install plungers with

seals into ports

with metal seal

side into mani-

fold.

Press into posi-

tion using the larger I.D. end of discharge

adapter-seat. (Fig. D)

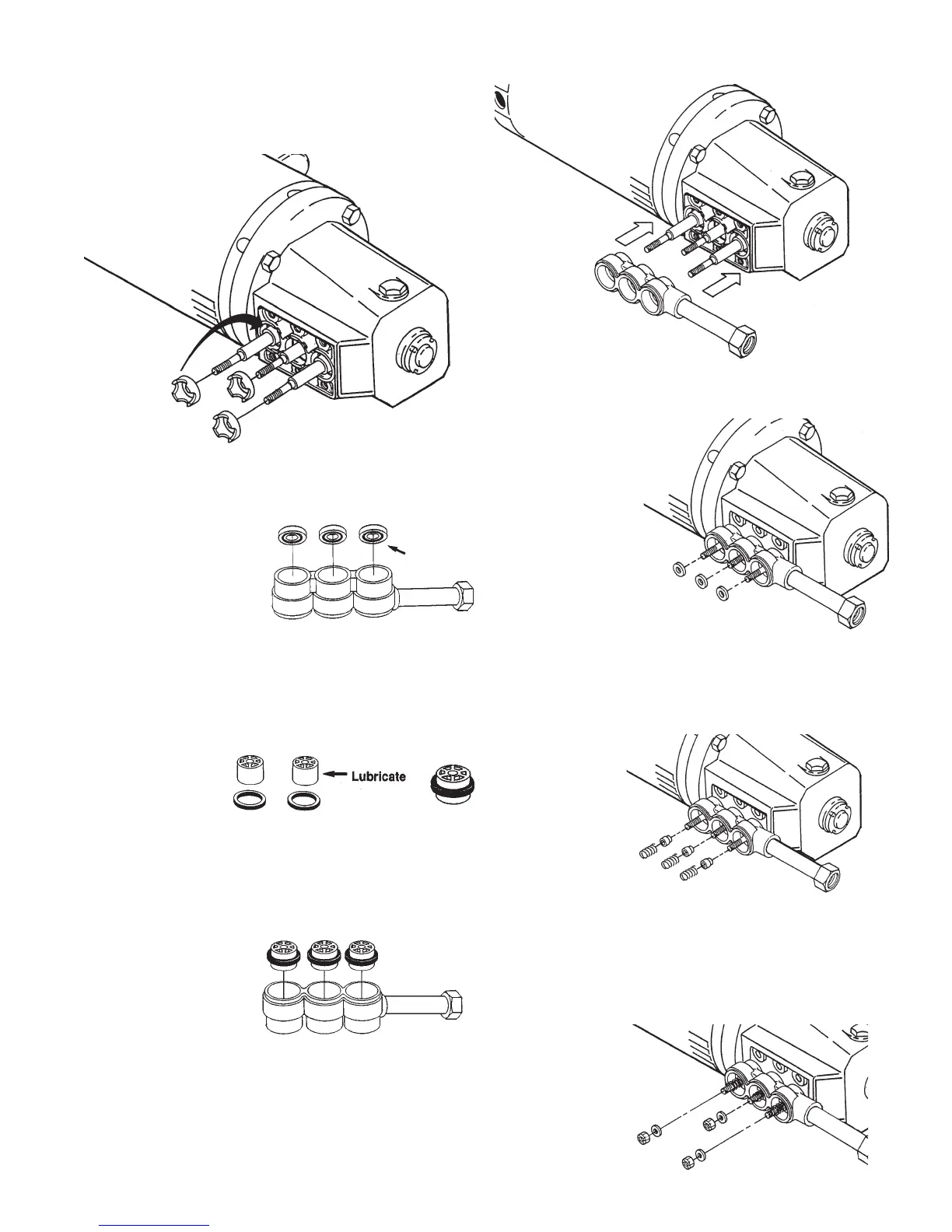

6. Carefully install manifold over plunger rod

ends and slowly press into crankcase.

(Figure E)

7. Examine inlet valve and replace if worn.

Inlet valve cannot be lapped or reversed

if worn. Install

new inlet

valve with

ridged side

facing away

from the

crankcase,

toward the

discharge.

(Figure F)

8. Examine spacers for wear and replace as

needed. Install spacer on each plunger

with smaller outside diameter (O.D.)

into inlet valve.

9. Examine

springs for

damage or

fatigue and

replace as

needed.

Place on

plunger

rods. (Figure G)

10.Install washers next with concave side

toward manifold.

11. Next install nuts and torque to specifica-

tions in TORQUE CHART. (Figure H)

Figure A

Figure E

Figure F

Figure G

Figure H

Figure B

Figure C

Figure D

Note: Position with

garter spring down.

Loading...

Loading...