PRESSURE ADJUSTMENT AND

GAUGE READING

Before using the cleaning system, the oper-

ating pressure must be set. The cleaning

system is equipped with a pressure gauge

for setting and monitoring system pressure.

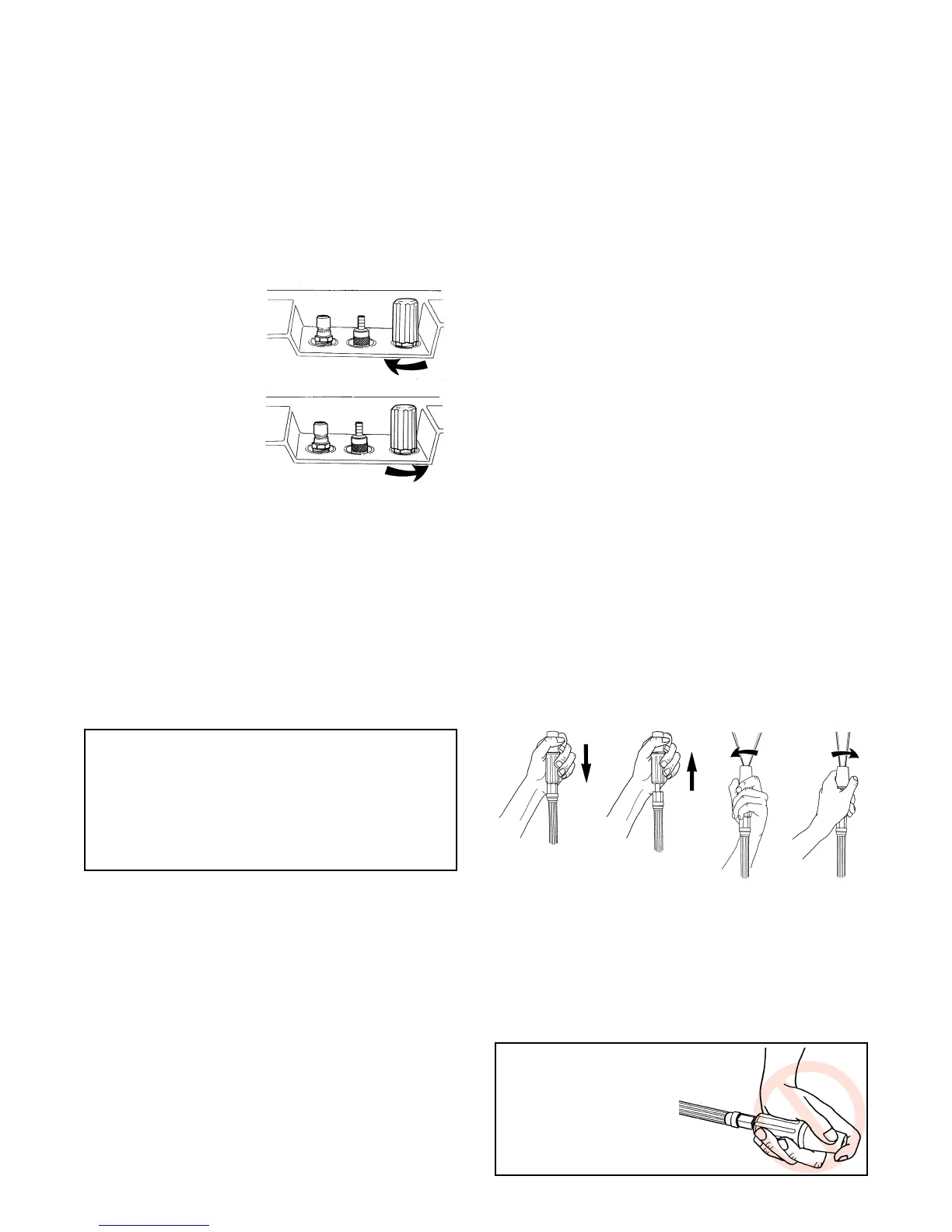

To set or adjust

pressure, rotate the

unloader adjustment

knob, marked “PSI”

on the top of the

case clockwise to

increase pressure

and counterclock-

wise to decrease

pressure. Make all

adjustments with the gun off (trigger

released). Adjust unloader 1/2 turn, squeeze

trigger and read pressure. If operating pres-

sure has not been reached, repeat until

desired pressure is reached. Do not exceed

the maximum operating pressure listed in

specifications. Be certain to use only the

Vari-Nozzle provided with cleaning system or

replacement nozzle sized for the flow and

pressure of unit.

Check your gauge while setting pressure

and periodically during operation. Changes

in pressure will warn you of wear or improper

operating conditions. If maximum pressure

cannot be reached or pressure drops after

prolonged use, it is most likely due to a worn

nozzle or lack of sufficient inlet water to the

unit. Consult “TROUBLESHOOTING” or call

your local service center.

When unit is running but in by-pass (gun off,

trigger released) pressure should drop to

approximately 100 PSI. If the pressure read-

ing on the gauge does not drop, trigger gun

several times and check reading. If pressure

still has not dropped shut the unit off and con-

sult “TROUBLESHOOTING”. For safety and

optimum life, operation in by-pass should not

exceed 6 minutes.The cleaning system is

equipped with an internal by-pass hose and

Thermo Valve. The Thermo Valve will sense

the rise in fluid temperature as a result of run-

ning the unit in by-pass and bleed a small

amount of heated water from the bottom of

the case. Cool inlet water will fill the line and

protect the pump from overheating.

Prolonged operation in by-pass at high

pressure may result in damage to the pump

or the unloader. Turn system “OFF” during

prolonged periods of nonuse.

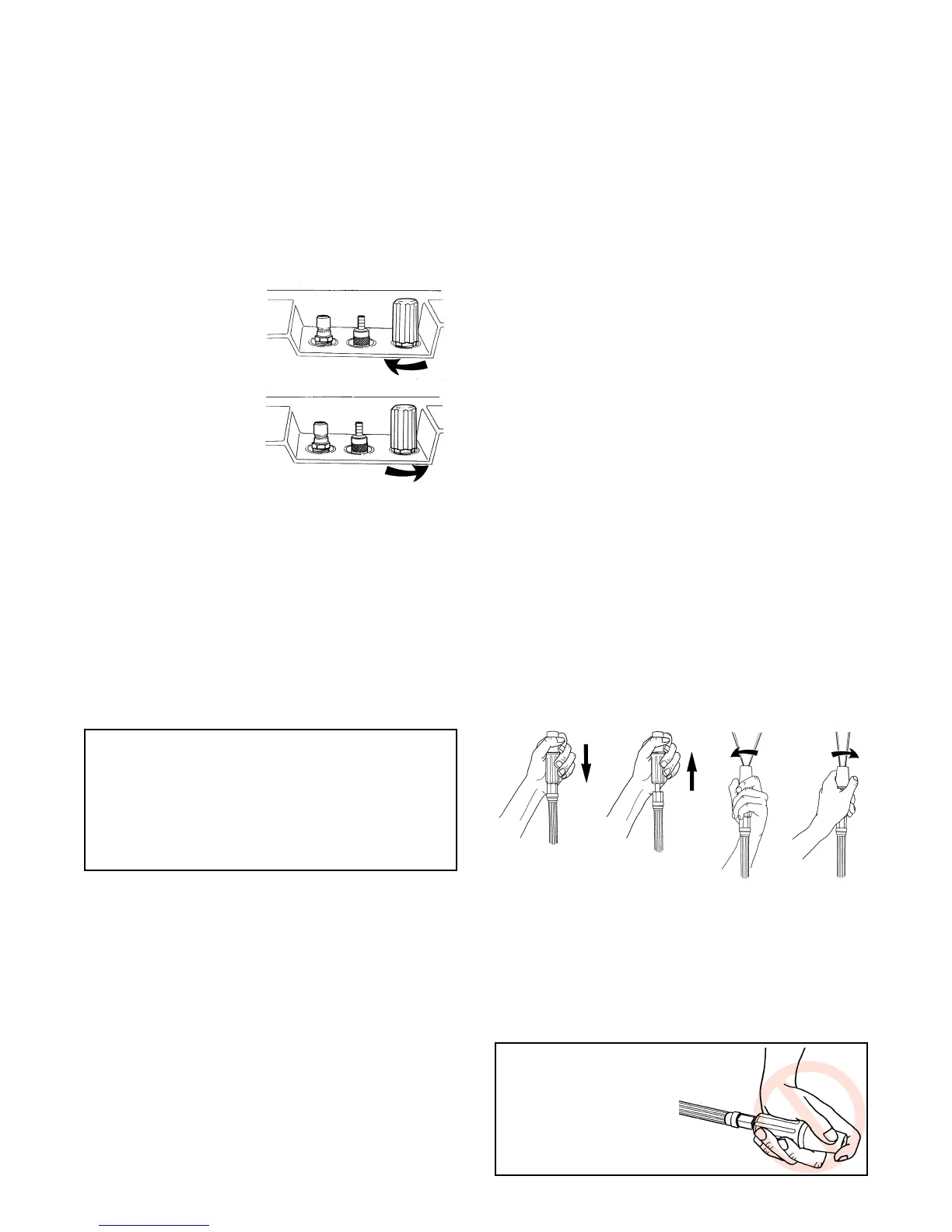

VARI-NOZZLE ADJUSTMENT

This unit is equipped with a multi-function

nozzle. The Vari-Nozzle changes from high

pressure (back position) to low pressure

(forward position) with an easy push-pull

motion. Changing from high to low pressure

permits the the low pressure adjustable chemi-

cal injector to begin drawing chemical into the

system. When chemical is no longer needed,

return to high pressure (back position). The

Vari-Nozzle will also rotate right to left to adjust

from a 0° to 60° spray angle for desired clean-

ing needs. Make high to low pressure adjust-

ments with gun off or trigger released.

▲ WARNING ▲

Do not place hand

over end of nozzle

while spraying or

adjusting nozzle.

8

OPERATION

CAUTION

The maximum operating pressure of your

cleaning system has been secured at the

factory with a Locking Collar. Tampering or

removal of the Locking Collar on the

unloader valve will VOID THE WARRANTY.

!!

HIGH

PRESSURE

LOW

PRESSURE

WIDE

SPRAY

NARROW

SPRAY

Loading...

Loading...