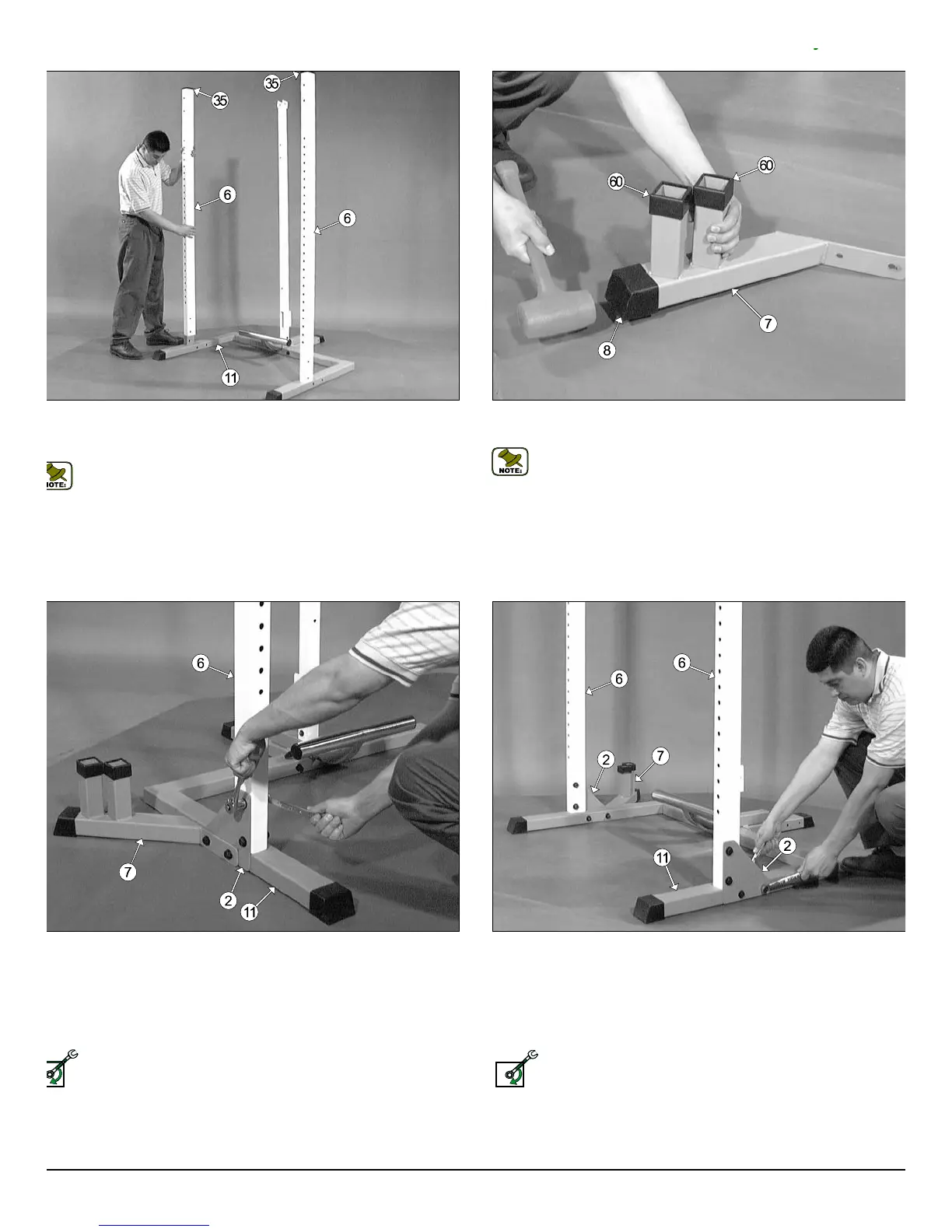

g. 5 Insert the two Selectorized Uprights (#6) onto the receptacles

cated on the Base Frame (#11), in the position as shown above with the

le pattern facing away from the unit.

Note: The two Plastic Insert Caps 2 X 3 (#35) located on top of the

Selectorized Uprights (#6) have been assembled by the factory.

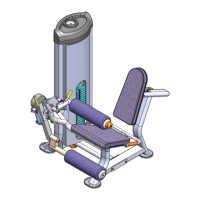

Fig. 6 Using a rubber mallet, insert one Plastic End Cap w/Groove 2 X

(#8) onto the tube-end of the Accessory Rack (#7).

Note: The two Plastic Tube Guides 2” Sq. (#60) located on the A

cessory Rack (#7) have been assembled by the factory.

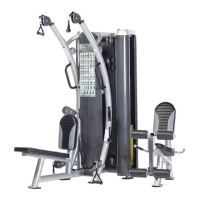

g. 7 Attach the Accessory Rack (#7) and a Triangular Corner Plate

2) to the Base Frame (#11), in the position as shown above, using two

ex Head Cap Screws 1/2-13 X 4 1/2 (#14), four Flat Washers SAE

2” (#10), and two Nylon Insert Lock Nuts 1/2-13 (#9). Next, affix the Trian-

lar Corner Plate (#2) to the Selectorized Upright (#6) using two Hex

ead Cap Screws 1/2-13 X 3 (#13), four Flat Washers SAE 1/2” (#10), and

o Nylon Insert Lock Nuts 1/2-13 (#9).

Loosely Fasten: Do not completely fasten this hardware assembly

at this time, as it will be completely fastened later in the assembly

process.

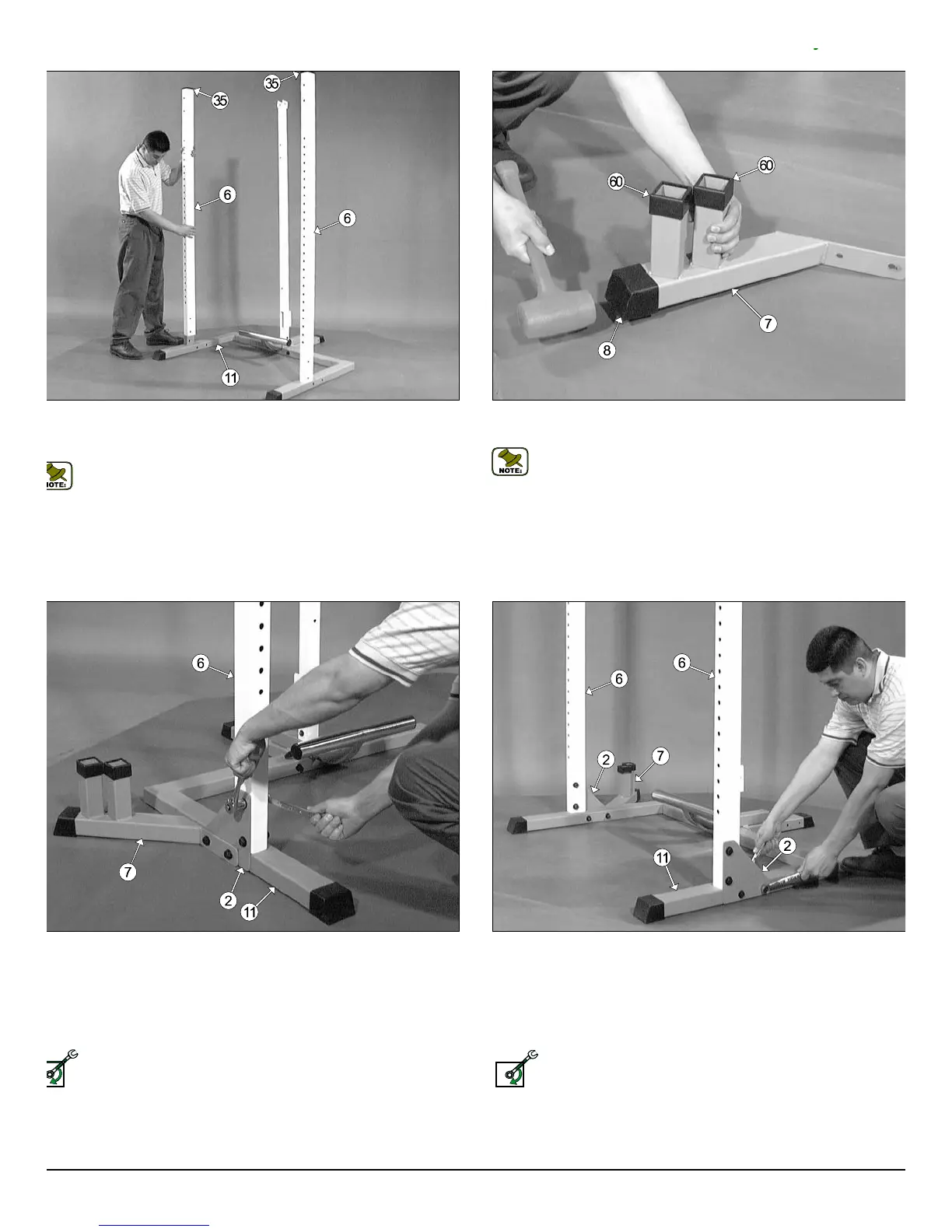

Fig. 8 Attach a Triangular Corner Plate (#2) to the Selectorized U

right (#6), in the position as shown above, using two Hex Head Cap Scre

1/2-13 X 3 (#13), four Flat Washers SAE 1/2” (#10), and two Nylon Inse

Lock Nuts 1/2-13 (#9). Next, affix the Triangular Corner Plate (#2) to t

Base Frame (#11), using two Hex Head Cap Screws 1/2-13 X 4 1/4 (#12

four Flat Washers SAE 1/2” (#10), and two Nylon Insert Lock Nuts 1/2-1

(#9).

Loosely Fasten: Do not completely fasten this hardware assemb

at this time, as it will be completely fastened later in the assemb

process.

ELY FASTEN

LOOSELY FASTEN

TDH 345 Half Cage Ensemble

4

Loading...

Loading...