0807

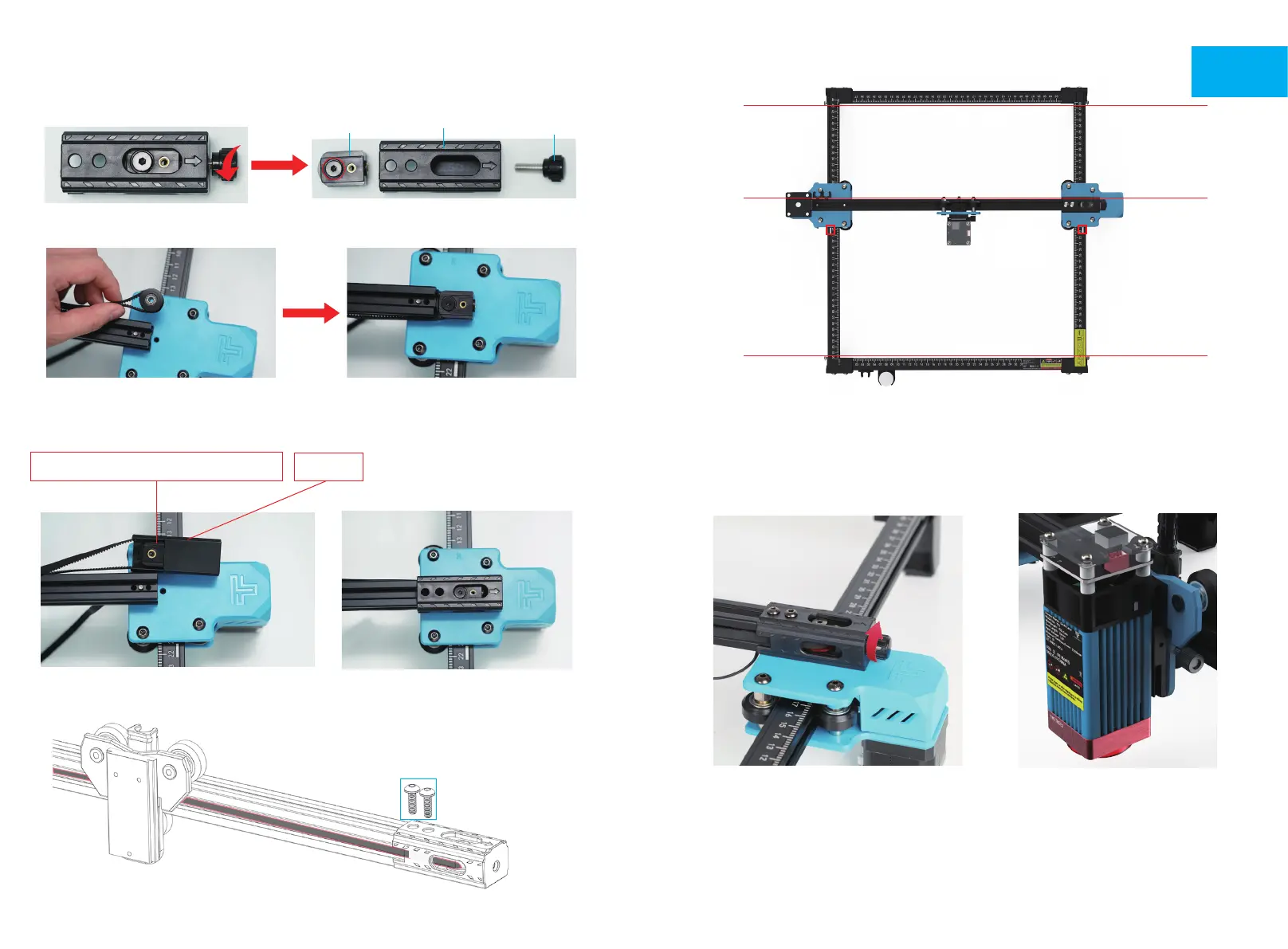

3.5 Tensioner Installation

Tensioner

Internal parts

Tensioner

shell

Thumb

screws

① You need to disassemble the tensioner first, unscrew the hand screw of the tensioner

to take out the Tensioner Inner Parts and unscrew the top screw to take out the idler.

② Put the timing belt of the carriage on the idler of the tensioner, and then lock the

screw to the inner part of the tensioner

③ Push the tensioner internals into the tensioner housing shell (Tensioner has a fixed

slot, pay attention to the installation method)

Tensioner has slot, pay attention to assemble them in

right direction and push them in into the right position

Tensioner

housing shell

screw M4*20 x2

④ Lock up the tensioner retaining screws

The teeth of the timing belt should face the guide groove

M4*20

EN

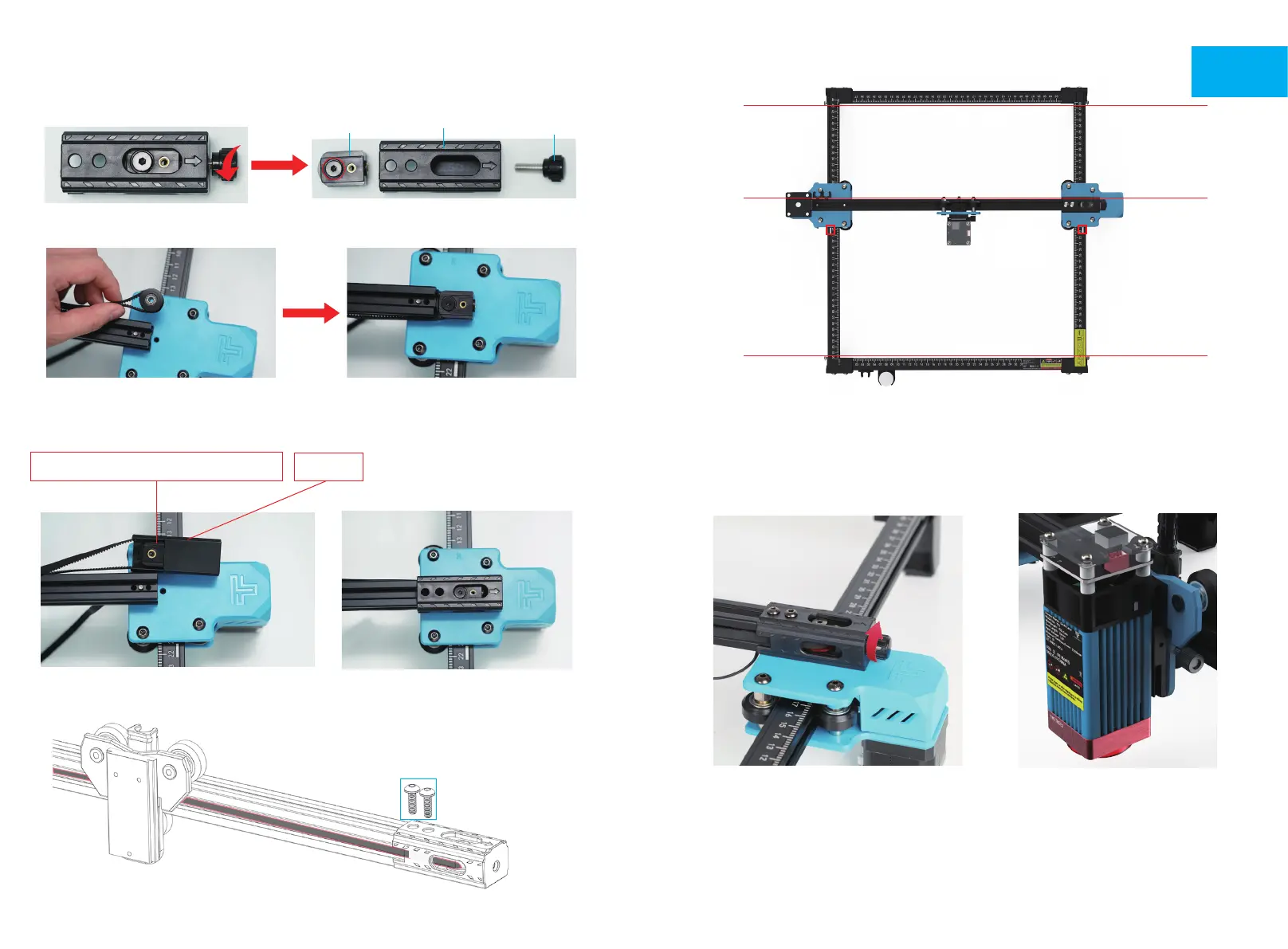

Note: When installing, please make sure that the X-axis beam is parallel to the front and

rear beam profiles. You can use the rectangle on the scale for auxiliary adjustment.

Without parallelism, the Y-axis will be difficult to move and affect the engraving effect.

4. Adjust the X-axis beam to make sure it is parallel with the front

and back frame.

5. Tighten the X-axis synchronous belt.

Tighten the thumb screw

Note:

Synchronous belt needs to be tightened, otherwise it

may cause the problem of engraving misalignment.

Thumb screw

Note: Install the laser module

at a vertical angle (90°).

Note:

① It is the most appropriate position to feel a

little friction between the POM wheel and the profile

when rotating the POM wheel.

② If the wheel rotates in the air and does not fit

the profile, the eccentric nut can be adjusted

clockwise from the direction of the screw head with

an open-end wrench.

Loading...

Loading...