TFP1090

Page 4 of 26

Technical

Data

Approvals

Model DPV-1 Dry Pipe Valves with

or without the TYCO Model ACC-1

Dry Pipe Valve Accelerator are FM,

LPCB, VdS, and CE Approved with

European Conformity Valve Trim. See

Figures 7 to 18.

For more information on Agency

Approvals, contact Johnson Controls

at the following office:

Kopersteden 1

7547 TJ Enschede

The Netherlands

Tel: +31-(0)53-428-4444

Fax: +31-(0)53-428-3377

Dry Pipe Valve

The DN65, DN80, DN100, and DN150

Model DPV-1 Dry Pipe Valves are

for vertical installations (flow going

up), and they are rated for use at a

maximum service pressure of 16 bar.

The nominal pressure loss versus flow

is shown in Graph A, and the valve

take-out dimensions are shown in

Figure 2.

Flange connections are drilled per ISO

2084 (PN10/16) or ANSI B16.1 (Class

125). The grooved outlet connections,

as applicable, are cut in accordance

with standard groove specifications

for steel pipe. They are suitable for use

with grooved end pipe couplings that

are listed or approved for fire protec-

tion system service.

Threaded port connections per ISO

7-1 readily accept trim arrangements

described in Figures 7 through 18.

Components of Model DPV-1 Valve

assemblies are shown in Figure 1A

for the DN65, DN80, and DN100

valves and in Figure 1B for the DN150

valve. The Body and Handhole Cover

are ductile iron. The Handhole Cover

Gasket is neoprene, and the Clapper

Facing is EPDM. The Air/Water Seat

Ring is brass, the Clapper is copper,

and both the Clapper Retaining Plate

and Latch are bronze. The Hinge Pin is

aluminum bronze, and the fasteners for

the Handhole Cover are carbon steel.

Valve Trim

Valve trim arrangements are shown in

Figures 7 through 18. See Table A. The

Valve Trim forms a part of the labora-

tory approval of the Model DPV-1 Dry

Pipe Valve and is necessary for the

proper operation of the Model DPV-1

Dry Pipe Valve. Each package of trim

includes the following items:

• Water Supply Pressure Gauge

• System Air Pressure Gauge

• Main Drain Valve

• Low Body Drain Valve

• Alarm Test Valve

• Automatic Drain Valve

• Provision For An Optional Accelerator

Air Supply

Table B provides system air pressure

requirements as a function of the water

supply pressure. The air (or nitrogen)

pressure in the sprinkler system is rec-

ommended to be automatically main-

tained by using one of the following

pressure maintenance devices, as

appropriate:

• Model AMD-1 Air Maintenance

Device (pressure reducing type).

Refer to Technical Data Sheet

TFP1221.

• Model AMD-2 Air Maintenance

Device (compressor control type).

Refer to Technical Data Sheet

TFP1231.

• Model AMD-3 Nitrogen Mainte-

nance Device (high pressure reduc-

ing type). Refer to Technical Data

Sheet TFP1241.

Quick Opening Device

As an option, the Model DPV-1 Dry

Pipe Valve may be acquired with the

Model ACC-1 Dry Pipe Valve Acceler-

ator. See Figure 4. The Model ACC-1

Dry Pipe Valve Accelerator is used to

reduce the time to valve actuation fol-

lowing the operation of one or more

automatic sprinklers.

Operating

Principles

Dry Pipe Valve Operation

The TYCO Model DPV-1 Dry Pipe Valve

is a differential type valve that utilizes a

substantially lower system (air or nitro-

gen) pressure than the supply (water)

pressure, to maintain the set position

shown in Figure 3A. The differential

nature of the Model DPV-1 Dry Pipe

Valve is based on the area difference

between the air seat and the water

seat in combination with the ratio of the

radial difference from the Hinge Pin to

the center of the Water Seat and the

Hinge Pin to the center of the Air Seat.

The difference is such that the Model

DPV-1 has a nominal trip ratio of 5.5:1

(water to air).

Table B establishes the minimum

required system air pressure that

includes a safety factor to help prevent

false operations that occur due to water

supply fluctuations.

The Intermediate Chamber of the Model

DPV-1 Dry Pipe Valve is formed by the

area between the Air Seat and Water

Seat as shown in Figure 3B. The Inter-

mediate Chamber normally remains

at atmospheric pressure through the

Alarm Port connection and the valve

trim to the normally open Automatic

Drain Valve. See Figures 7 to 18. Having

the Intermediate Chamber, Figure 3B,

open to atmosphere is critical to the

Model DPV-1 Valve remaining set, oth-

erwise the full resulting pressure of

the system air pressure on top of the

Clapper Assembly cannot be realized.

For example, if the system air pres-

sure is 1,7 bar and there was 1,0 bar

pressure trapped in the Intermediate

Chamber, the resulting pressure across

the top of the Clapper would only be

0,7 bar. This pressure would be insuf-

ficient to hold the Clapper Assembly

closed against a water supply pres-

sure of 6,9 bar.

When one or more automatic sprinklers

operate in response to a fire, air pres-

sure within the system piping is relieved

through the open sprinklers. When the

air pressure is sufficiently reduced,

the water pressure overcomes the dif-

ferential holding the Clapper Assem-

bly closed and the Clapper Assembly

swings clear of the water seat, as

shown in Figure 3C. This action permits

water flow into the system piping and

subsequently to be discharged from

any open sprinklers. Also, with the

Clapper Assembly open, the interme-

diate chamber is pressurized and water

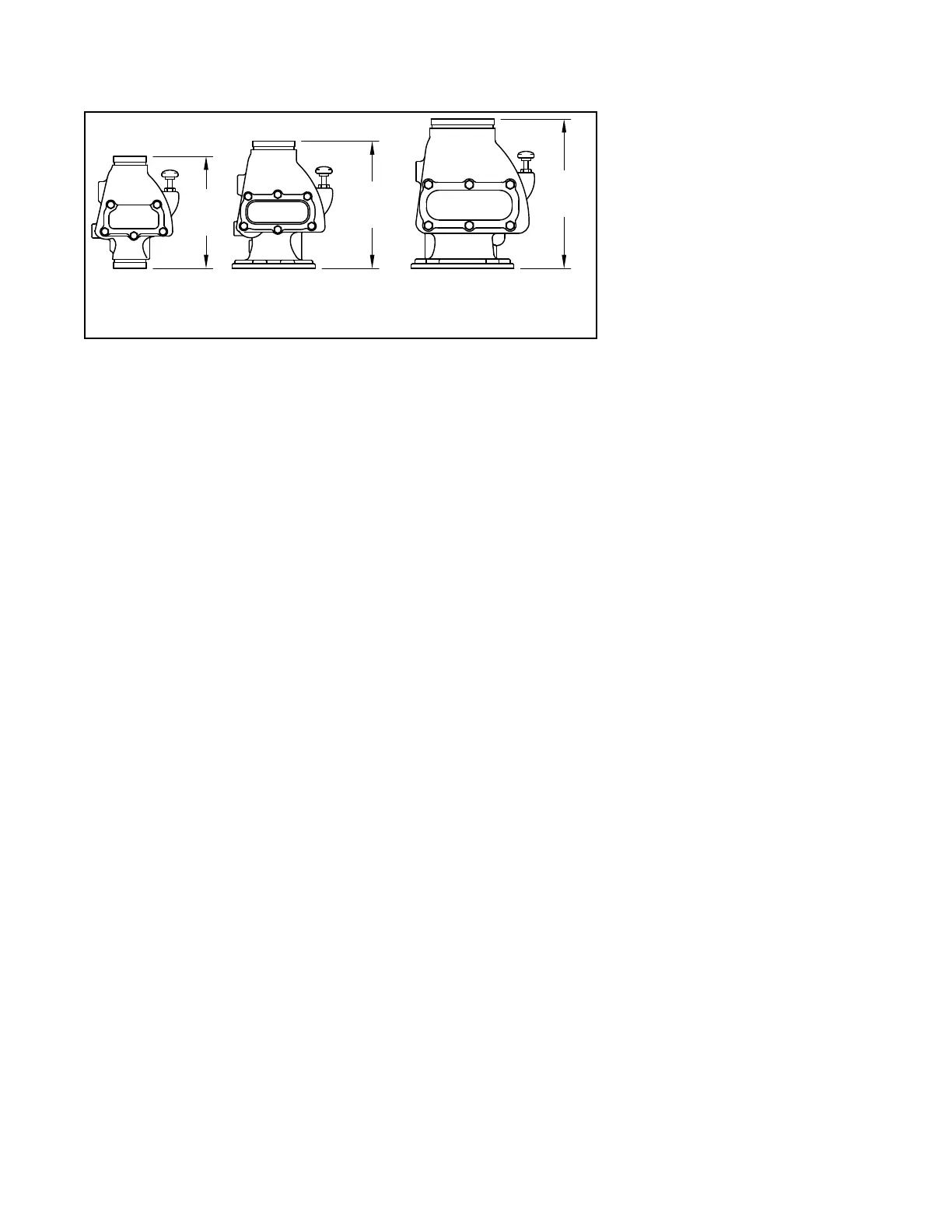

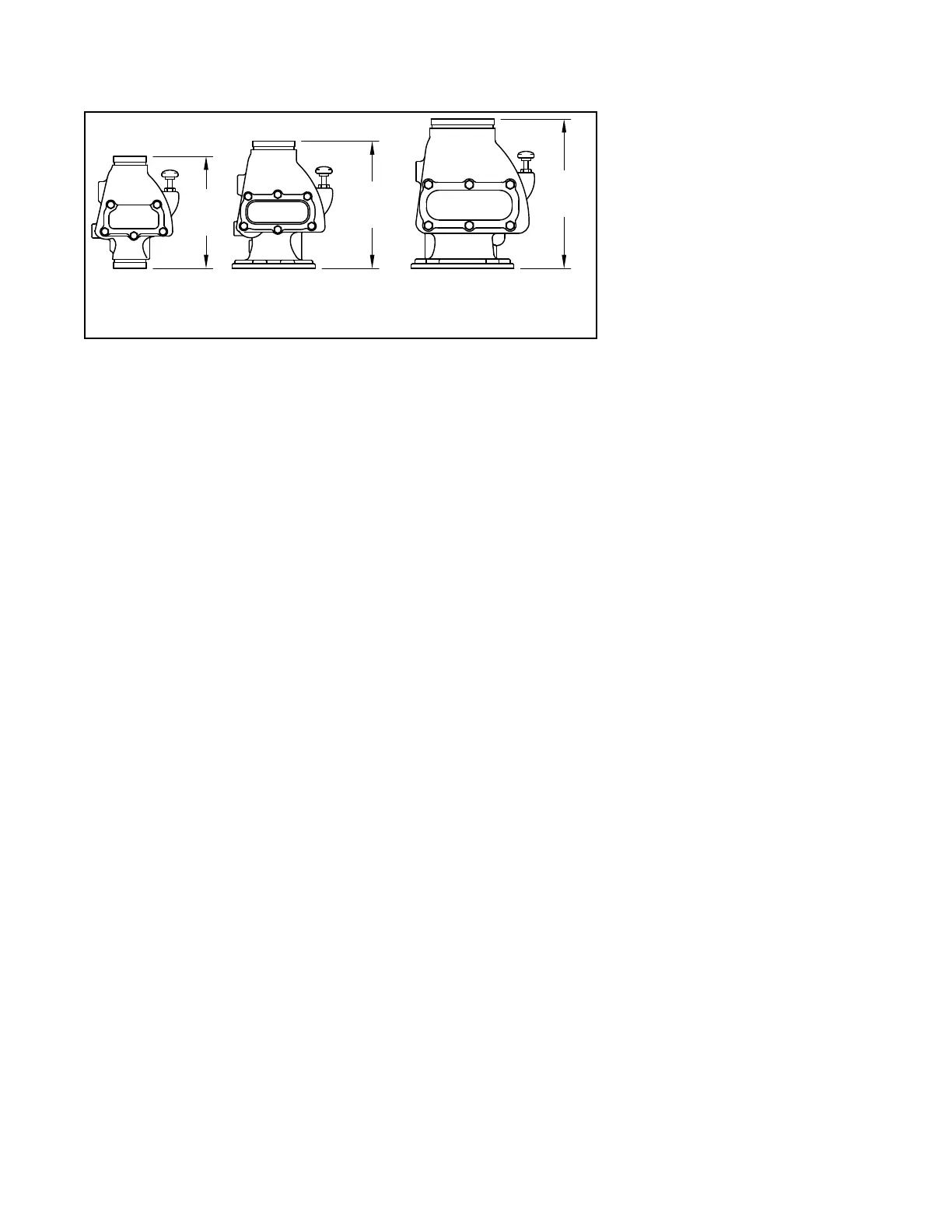

DN100 DN150DN65, DN80

FxF, FxG,

406 mm

or GxG

FxG 348 mm

FxF 346 mm

GxG 349 mm

GxG

311 mm

ONLY

FIGURE 2

MODEL DPV-1 DRY PIPE VALVE

TAKE-OUT DIMENSIONS

Loading...

Loading...