3

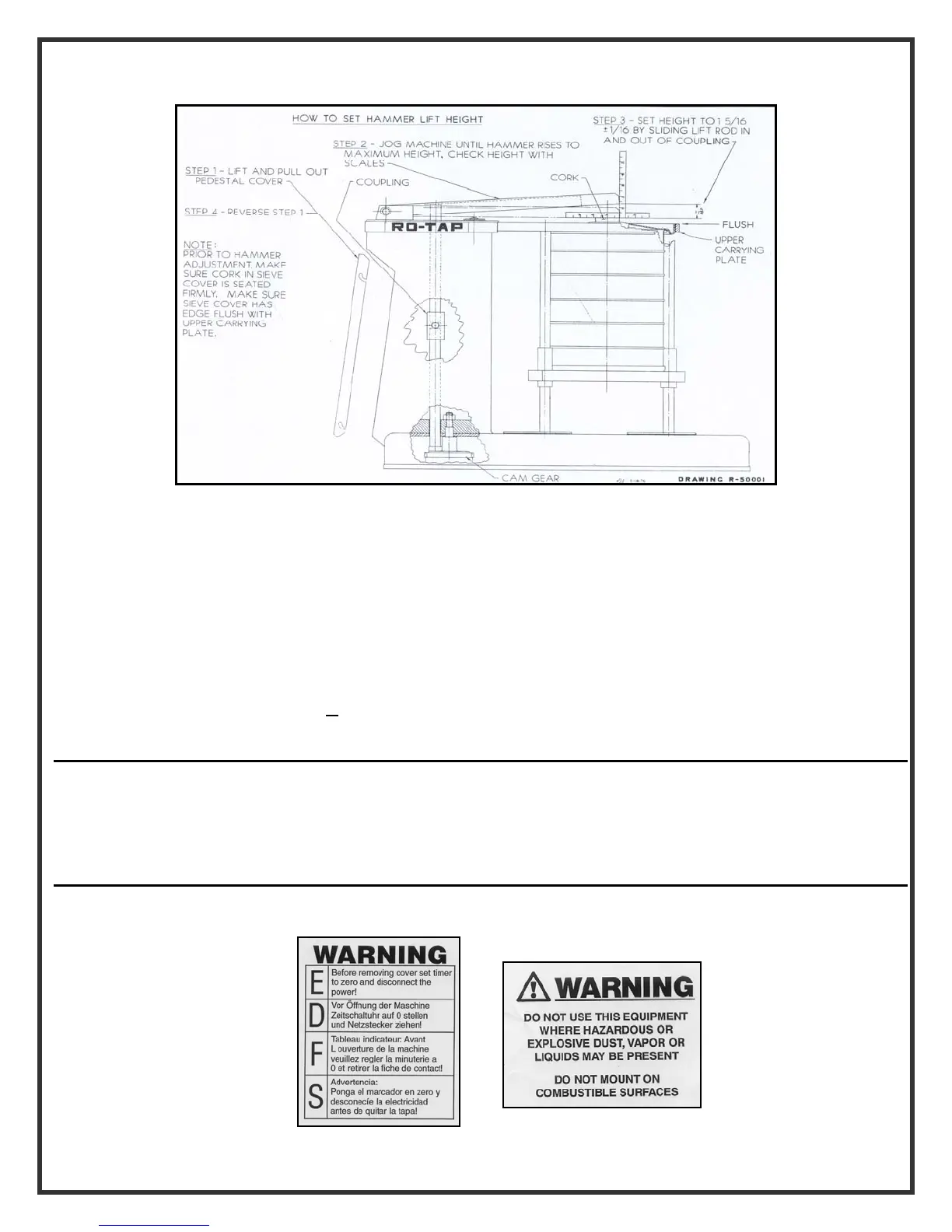

HAMMER DROP ADJUSTMENT

PLUG

SETTING THE HAMMER LIFT HEIGHT

Ro-Tap

®

MODELS: RX-29 and RX-30 and RX-94

(NOTE: THIS SETTING HAS BEEN MADE ON ALL NEW UNITS)

NOTE: Prior to hammer adjustment; make sure plug is seated firmly in sieve cover.

Make sure sieve cover has top edge flush with upper carrying plate. A stack of sieves

must be used to achieve this setting.

STEP 1: Remove pedestal cover.

STEP 2: Jog machine until hammer rises to maximum height or use a box wrench on the hex

head screw, located on top of the pedestal. Check height with scales.

STEP 3: Set height to 1-5/16 +

1/16” by loosening screw on coupling and adjusting lift rod.

STEP 4: Tighten screw on coupling.

STEP 5: Replace pedestal cover.

Lubrication

The Tyler Sieve Shakers require only minimal periodic lubrication. The units incorporate plastic and oil-

impregnated bronze bearing materials, which are self-lubricating. A few drops of light oil or WD-40™ every six

months is all that is necessary to prevent drying of the parts. Application of the same lubricants will suffice if a

squeak or a drag should develop in the mechanism.

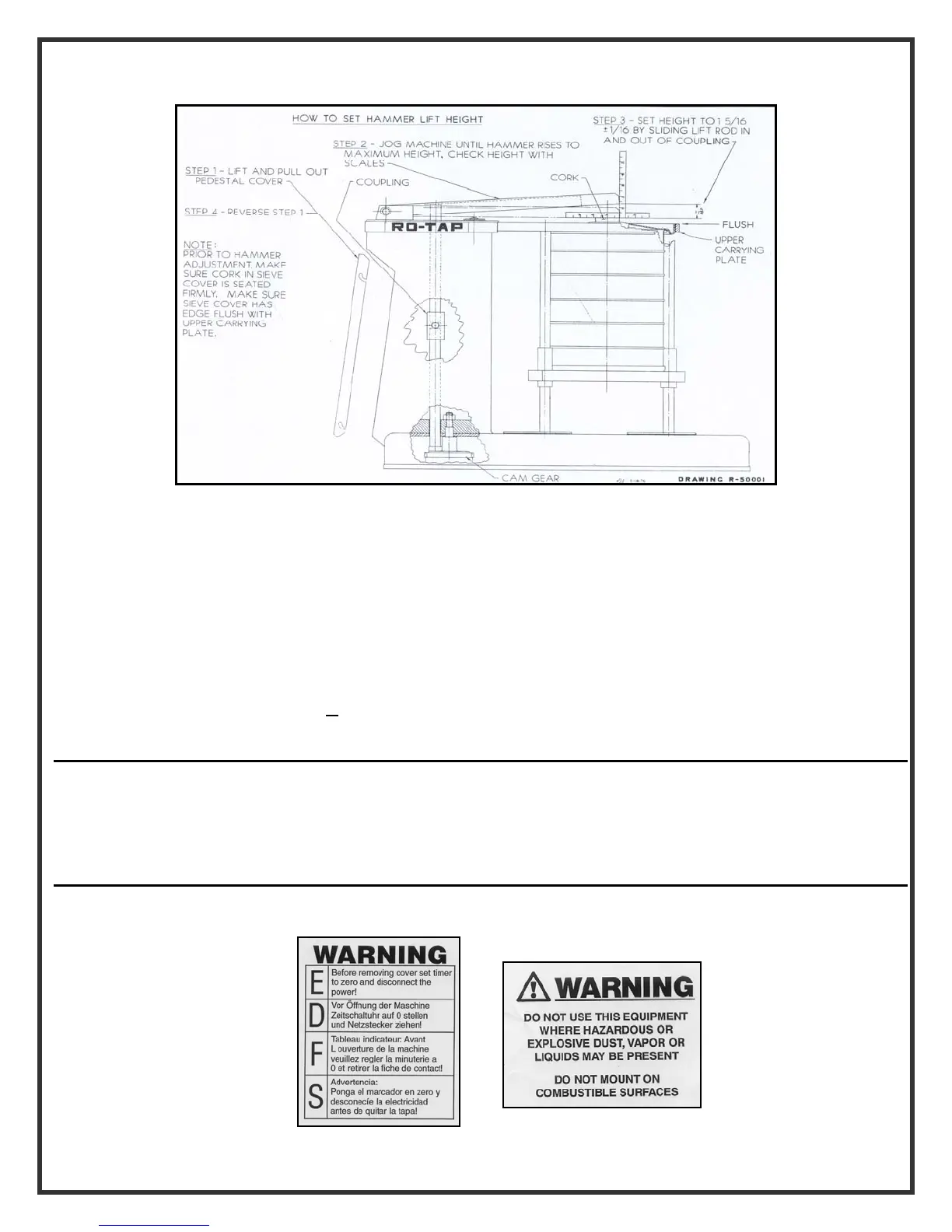

PLEASE BE ADVISED: Review these warnings prior to use

Loading...

Loading...