2

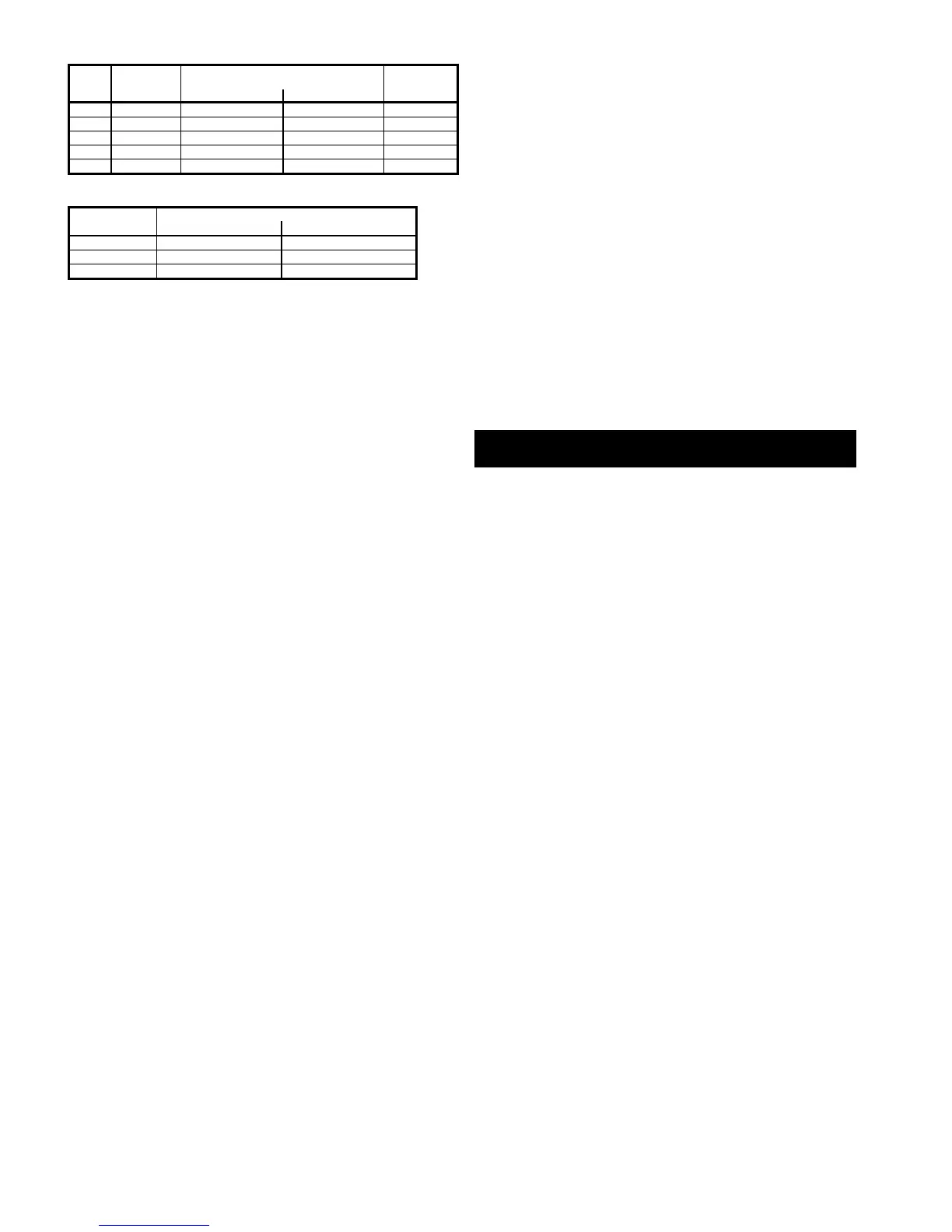

Sauna volume and min. installation distances:

Output Sauna volume Min. distance from side wall (in.)

Minimum ceiling

height

kW min/max cu.ft. normal installation “X” recess installation “Y” in sauna (in.)

2,2-4,5 70-210 4 8 74

5,3 - 7 140 -320 4 8 74

6,3 - 8 175 - 440 4 8 74

10.7 320-640 6 8 74

16 586-1080 6 14 83

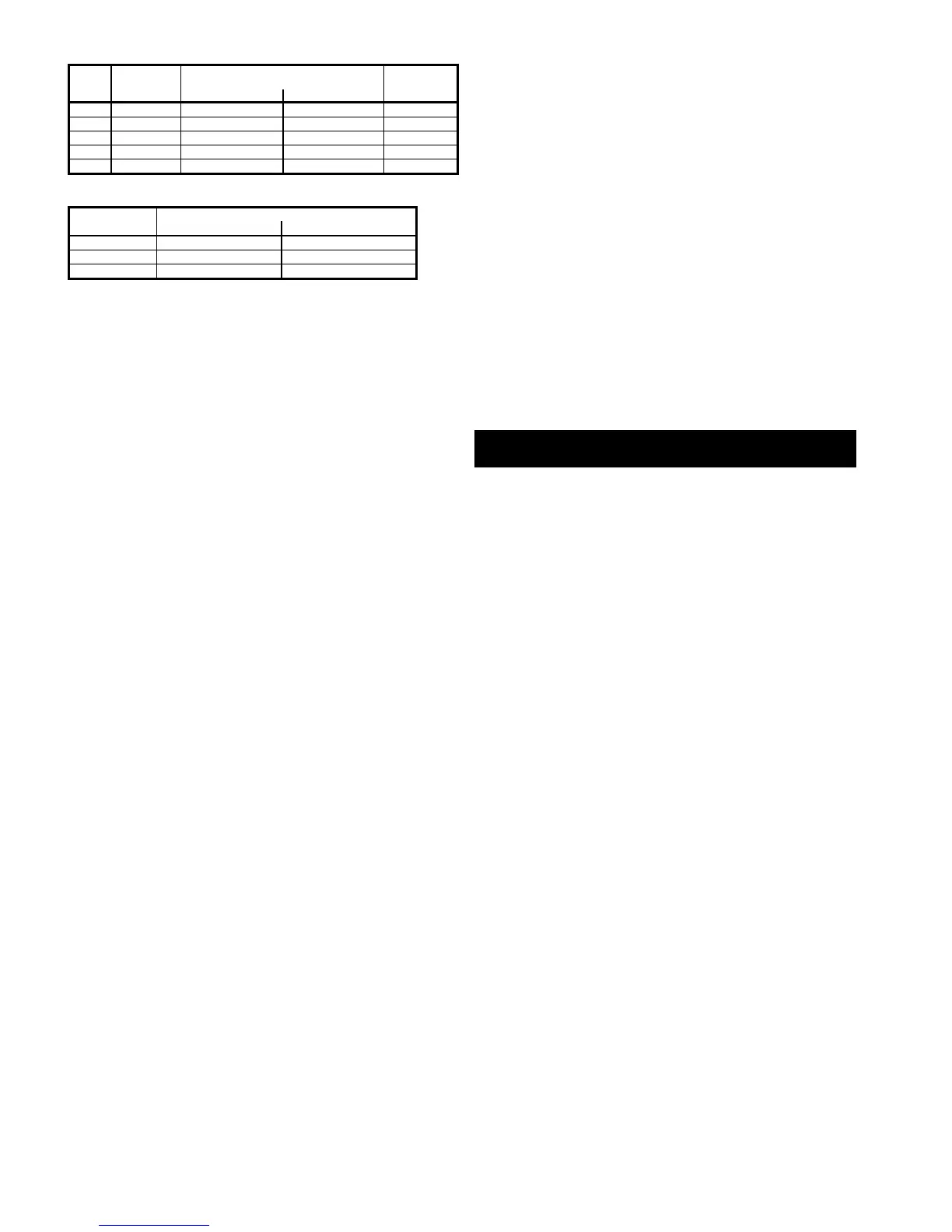

Sauna heater – separate control panel combinations

Heater Suitable control panel

type 240 V 1~ 208 V 3~

Deluxe 7-8-11 TS 30-01, CC/RB 30 TS 30-01, CC/RB 30

Deluxe16 - TS 58/1RB, CC/RB 60

SE-U 7-U8 CC -

Installation of separate control panels.

A separate control panel is required for the Tylö Deluxe and SE-U heaters. The control

panel must be assembled outside the sauna.

TS-type control panels

TS panels are thermally operated and have a patented divided output. They can either

mounted on the wall or recessed for a flush fit (fig. 12). It is essential to fit insulation

behind control panels recessed into the wall. The standard length of the capillary tube

is 73 in., but a 197 in. capillary tube is also available.

Installing a sensor for a TS control panel (fig. 13). A=capillary tube. B=sensor

holder. C=plastic holder for capillary tube. D=sensor that is installed 59 in. above

floor level (fig. 12, not above the sauna heater).

Extra equipment for the TS control panel.

Locking cover in transparent plastic to fit over the control panel. Available in designs

to prevent unauthorized interference with time and temperature settings, or

temperature only.

Figs. 22, 26 Wiring diagrams.

(With sauna heater Sport - U, Supersport and Combi - U with built-in control

panels).

1=sauna heater.

Check the heater’s type identification plate to ensure that the heater is connected to

the right voltage.

Don’t forget – The installation must be earthed!

Figs. 23, 27, 29 Wiring diagrams.

(With sauna heater Deluxe and control panel TS ).

1=sauna heater. 2=control panel. 3=relay box.

Check the heater’s type identification plate to ensure that the heater is connected to

the right voltage.

Don’t forget – The installation must be earthed!

Remote control operation.

TS control panels use contactors for remote control operation. Please request special

wiring diagram.

CC control panels.

Instructions: included with the control panel.

Can be installed at any distance from the sauna room.

CC panels are electronically operated and are available in the following models:

CC 10-1. Manual and automatic on/off. A maximum of one hours' running time,

10 hours' pre-set time.

CC 50-1. Manual and automatic on/off. A maximum of one hours' running time,

10 hours' pre-set time.

CC 100-1. Manual and automatic on/off. A maximum of one hours' running time,

24 hours' pre-set time.

CC 100-0. Built-in weekly timer. A maximum of 12 hours' continuous running time.

Placement of the thermistor (sensor).

59 in. above floor level (not above the sauna heater).

The thermistor wire can be lengthened outside of the sauna with a partially enclosed

low-voltage cable (2-core).

The thermometer in the sauna should be placed at a height so that the temperature

corresponds exactly to the numbers displayed on the CC 50/CC 100.

Relay box (RB).

(No relay box is used for SE-U heaters).

Installed outside the sauna at any distance from it. The relay box may not be placed

closer than one meter from the CC 10/ CC 50/ CC 100.

Partially enclosed low-voltage cable (6-core, LiYCY).

The control cable between the CC 10/ CC 50/ CC 100 and the relay box or SE-U

heater must be a partially enclosed low-voltage cable (6-core, LiYCY). Connect the

shielding cable to plinth 12 in the CC-panel.

Lighting.

(Not CC 10)

Connect the lighting according to the wiring diagram.

Remote control operation.

CC control panels are already prepared for remote-control operation from one or more

locations.

Option: external on/off-switch (instantaneous).

Can be placed at any distance from the sauna. Connected with a low-voltage cable to

the CC 10/ CC 50/ CC 100 – see the wiring diagram. If there are several external

on/off switches, they should be parallel-connected.

Connection to a central computer.

The control panel can also be connected to a central computer, which gives a brief

impulse (closure) between plinths 19 and 20 in the CC 10/ CC 50/ CC 100. The

maximum permitted connection time for the sauna is 12 hours.

An instruction guide is included with the control panel.

Figs. 24, 25, 28, Wiring diagrams.

(With sauna heater Deluxe and SE-U and control panel CC ).

1=sauna heater. 2=thermistor (sensor). 3=control panel. 4=external on/off switch

(if any). 5=relay box.

Check the heater’s type identification plate to ensure that the heater is connected to

the right voltage. Don’t forget – The installation must be earthed!

Unusual voltages or number of phases.

Before connecting the heater to a different voltage or number of phases than those

described in the wiring diagram, contact Tylö Customer Service.

Building Instructions

The importance of correct sauna ventilation.

Incorrect sauna ventilation can result in hot floors and benches, scorched walls and

ceilings (the temperature limit control is triggered)! So we do urge you to follow our

instructions for sauna ventilation carefully.

Adjust the air outlet to evacuate 8-10.5 cubic yards. of air per person, per hour, when

the sauna is in operation.

Mechanical sauna ventilation is not to be recommended, as the forced air supply can

cause a fire hazard through the wooden panelling drying out.

Fig. 7. Sauna heater and door on the same wall.

The “air circulation” created by the door should work together with the hot air generated by

the heater. To facilitate this, the heater should be placed on the same wall as the door (If

exceptional circumstances require the heater to be fitted to a side wall, make sure it is

located in close proximity to the wall with the door).

Fig. 14. Inlet vent always directly below the heater.

The inlet vent should be driven straight through the wall directly below the center of the

heater. The cross-section of the vent for a family sauna is approx. 19 sq.in., for larger

saunas approx. 46 sq.in. If possible, it is an advantage to have a shower on the other

side of the wall. A flap valve may be fixed to the outside of the inlet vent to prevent

water seeping into the wall.

Fig. 15. The outlet vent should never discharge directly into

the open air.

Position the air inlet and outlet vents as far away from one another as possible

(diagonally opposite). The outlet vent should be located high on a wall or in the ceiling,

and should have the same cross-section area as the inlet vent.

Spent air should always be led back into the same room from which it is drawn into

the sauna – it must never be discharged directly into the open air. In this way, the air

flowing from the sauna is continually being replenished in the room outside. This

thermal ventilation method always works, no matter whether the pressure in adjacent

rooms is negative or positive.

If there is a gap above the sauna ceiling, do not seal it. To ventilate a cavity above the

sauna, drill or cut at least one ventilation hole into the cavity through the wall on which

the sauna door is located.

Alt. A: Outlet vent through the sauna wall (seen from above). The vent is placed high

up, near the ceiling.

Alt. B: Outlet vent through the cavity above the sauna ceiling (seen from the side).

Alt. C: Outlet vent through a drum under the ceiling in the sauna (seen from the side).

The outlet duct should be placed at an angle between the ceiling and the wall. The

drum can be built of wooden panelling and have the same area as the outlet vent.

Special information for steam saunas

(Combi-U and Tylarium):

Avoid placing the outlet vent so that it is led into a part of the building which is kept

cold. This eliminates the risk for condensation.

Loading...

Loading...