2008 7 210OPTRS

A. DUMP OPERATION & CLEAN OUT

To dump the hopper, use the following procedure:

1. Back sweeper to container or area for dumping.

NOTE: Raise the pick-up head before backing sweeper or damage could occur.

2. Start sweeper auxiliary engine and let idle.

3. Actuate dump toggle switch located on the left side of the sweeper behind cab so

hopper raises and unloads debris. Work hopper door back and forth several

times to fully discharge load.

WARNING

: Do not work under or around fully or partially raised hopper

without first installing pin in lower safety strut!

4. Lower hopper; never drive sweeper in transit with hopper in raised position.

5. At end of shift, raise hopper and install pin in safety strut. Wash out hopper,hop-

per screen and skimmer hood. Also wash out the separator, suction hose and

bottom of pick-up head.

HOPPER ASSEMBLY

The TYMCO® Model 210 hopper has a volumetric area of 2.4 cubic yards (1.8 m) and is sub

-

jected to the most severe working conditions of any area on the sweeper. The worst enemy of

the hopper assembly is CORROSION!

To prevent the hopper from rusting, it should be thoroughly washed at the end of each shift. It

should be pointed out that even a small rust-through area on the hopper will have dramatic ef

-

fect on the sweeper’s performance. The hopper is the vessel from which the blower draws air;

thus, creating the vacuum necessary to lift debris from the pavement. A small leak diminishes

this vacuum tremendously.

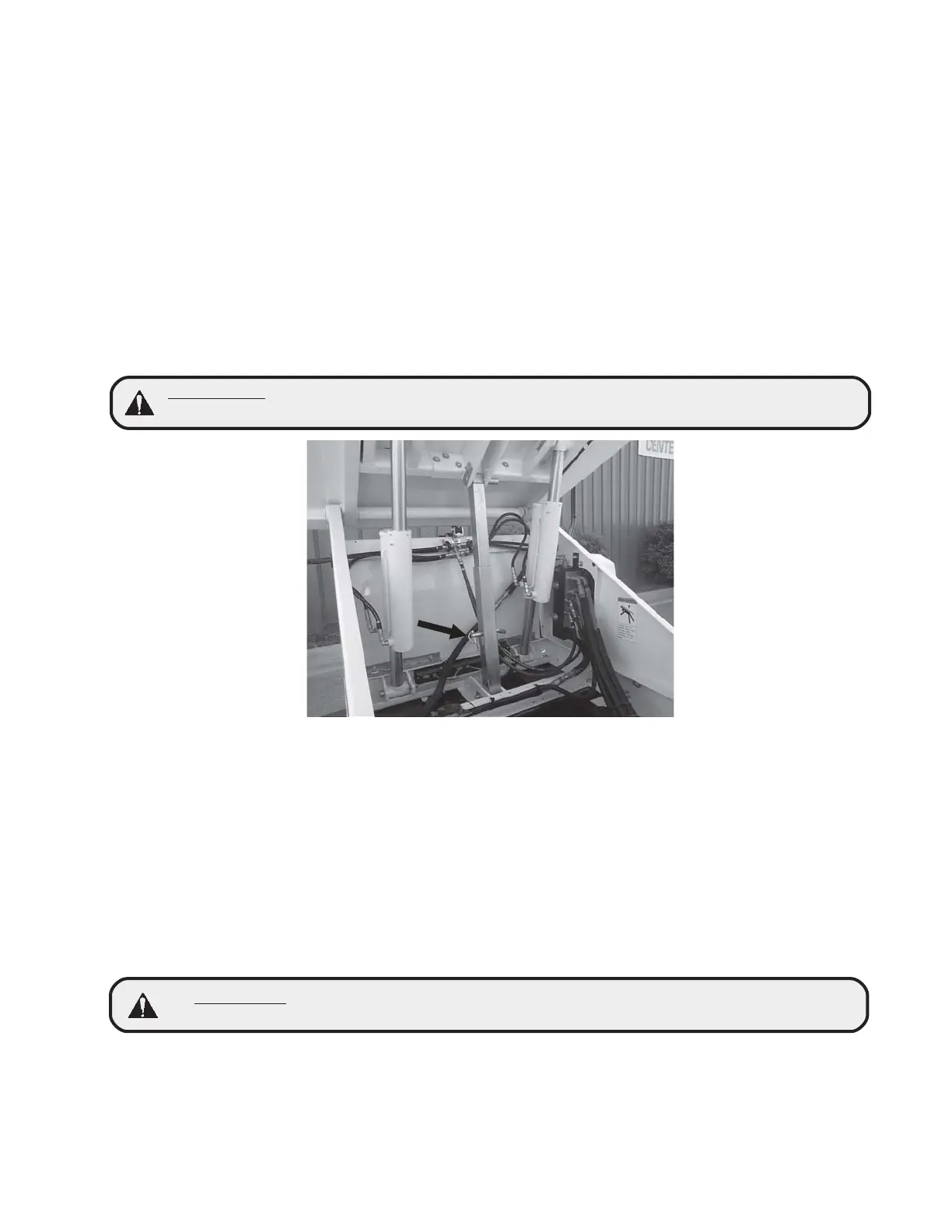

To empty the load from the Model 210, the hopper is made to high dump into containers up to

60 inches (152.4 cm) high. Two large hydraulic cylinders are used to raise the hopper which

pivots on a massive hinge.

WARNING!

Never work under or around raised hopper without first installing

pin in lower safety strut!

(M01216)

Loading...

Loading...