210OPTRS 12 2008

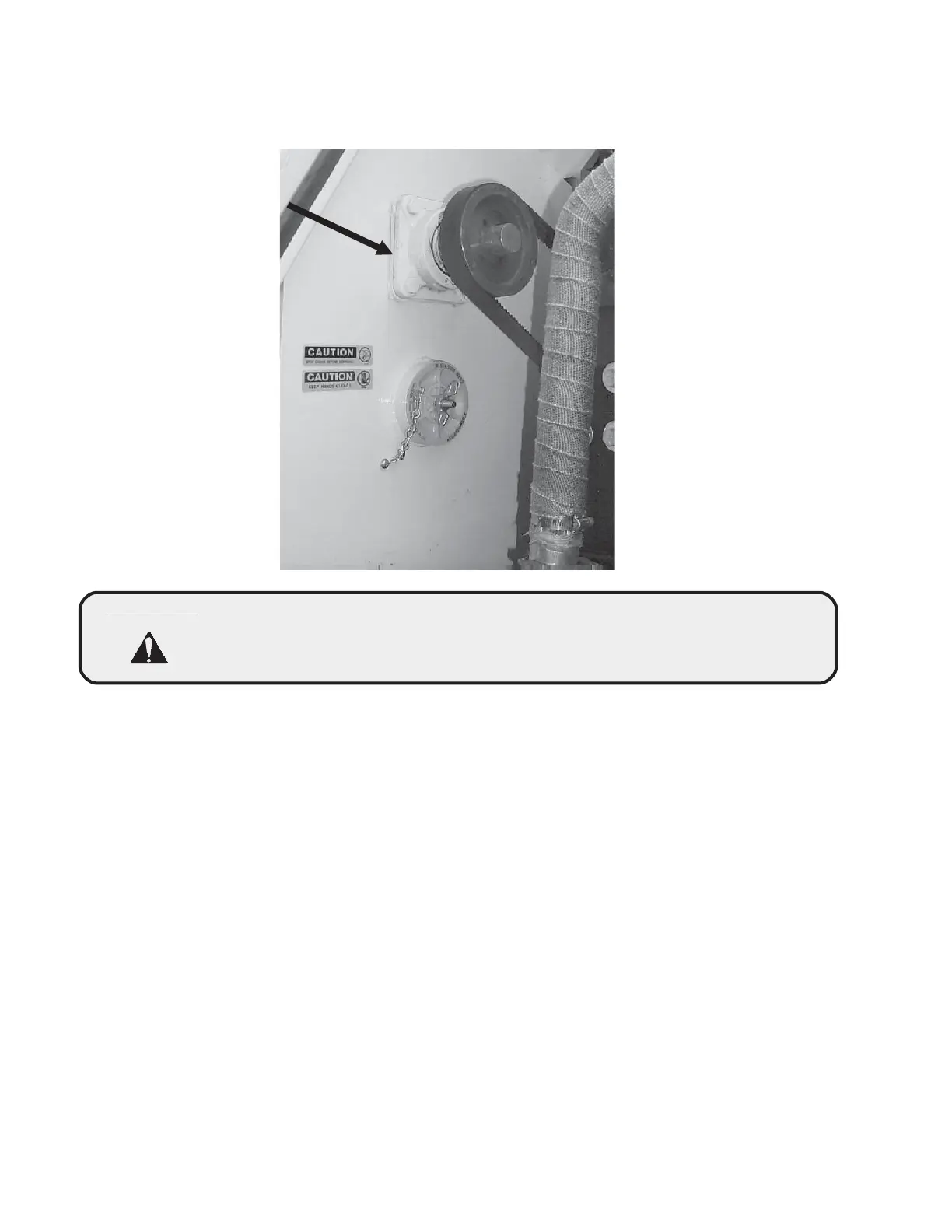

The second bearing is located on the right side of the separator next to the

engine assembly. Both of these bearings require greasing once a week.

BEARING

(M01384)

CAUTION:

Grease engine side bearing only when engine is not running.

Proximity to belt drives is hazardous when engine is running. Also

note that the hopper must be raised to access bearing. Always in-

stall pin in lower safety strut before working beneath raised hopper.

When lubricating the bearing, be careful not to apply too much grease! Use manual

hand type grease pump and pump the grease slowly into the bearing. A couple of

pumps is all that is necessary; too much grease will force out bearing seals and

cause premature bearing failure.

3. Have blower belt tensioned after initial 10 hours of operation; then every 150 hours

of operation or once a month. A loose belt will allow slippage and result in poor

sweeping performance as well as a damaged belt.

Loading...

Loading...