9

25

28

26

27

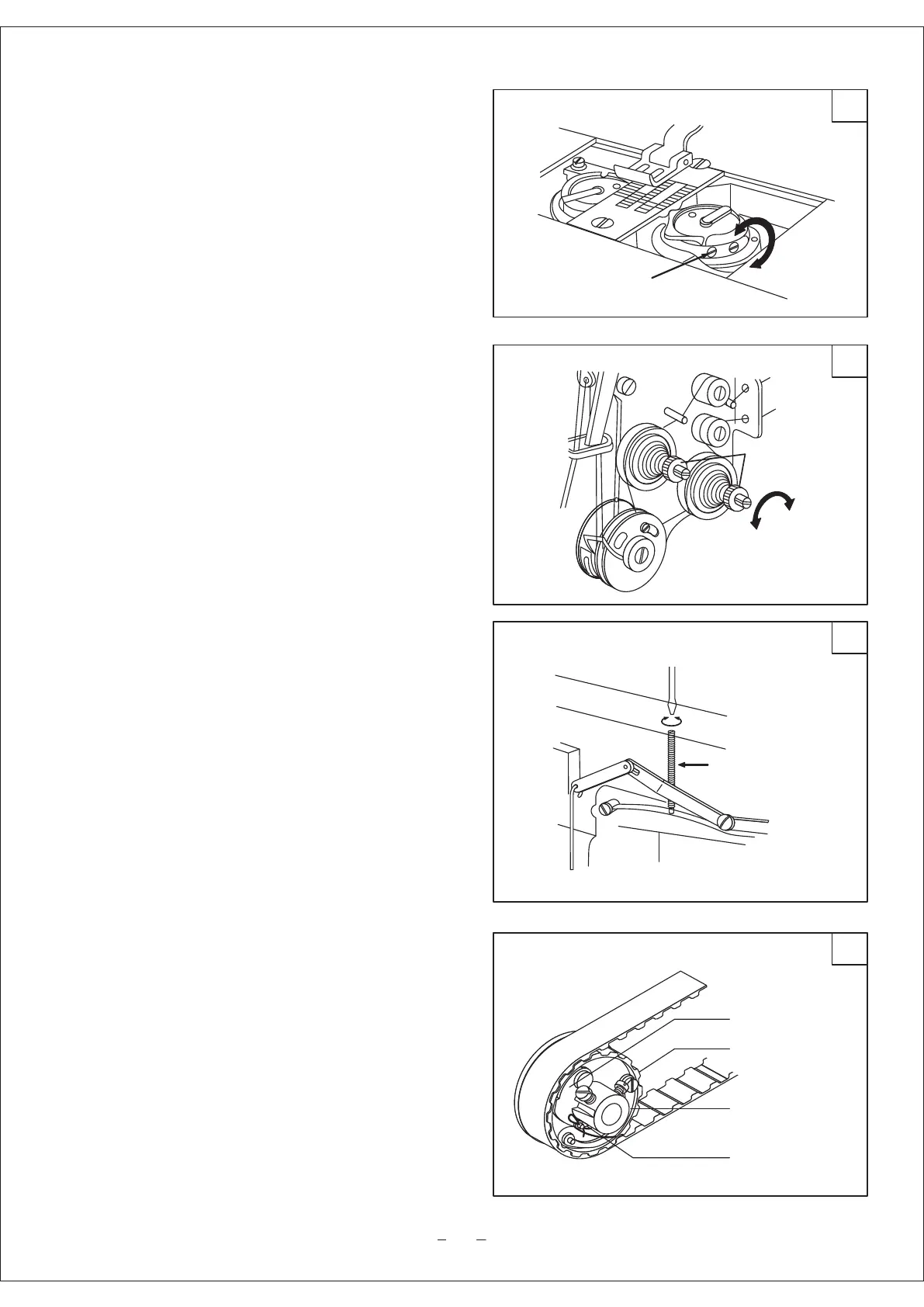

a.If the stiich form is the same as shown in Fig.24b, it

indicates that the needle thread is too tight or the bobbin

thread is too loose. Turn the thread tension screw counter

clockwise to release the needle thread tension, or turn the

adjusting screw with a screwdriver to increase the bobbin

thread tension (Fig.25.26).

b.If the needle thread is too loose and the bobbin thread

is too tight as shown in Fig,24c, turn the thread tension

screw clockwise to increase the needle thread tension,

or loosen the bobbin lace screw to reduce the bobbin

thread tension.(Fig.25,26).

For special sewing with special thread, the required

tension can be obtained by adjusting the strength and

stroke of the thread take-up spring.

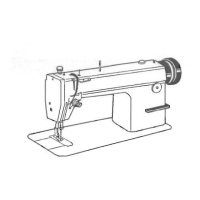

5.2 Adjusting the pressure of the presser foot (Fig.27)

The pressure of the presser foot should be adjusted

according to the thickness of the sewing materials. If

stitch on heavy duty materials, the pressure should be

increased by turning the pressure adjusting screw on

the back of the arm clockwise. To reduce the pressure,

turn it counter-clockwise.

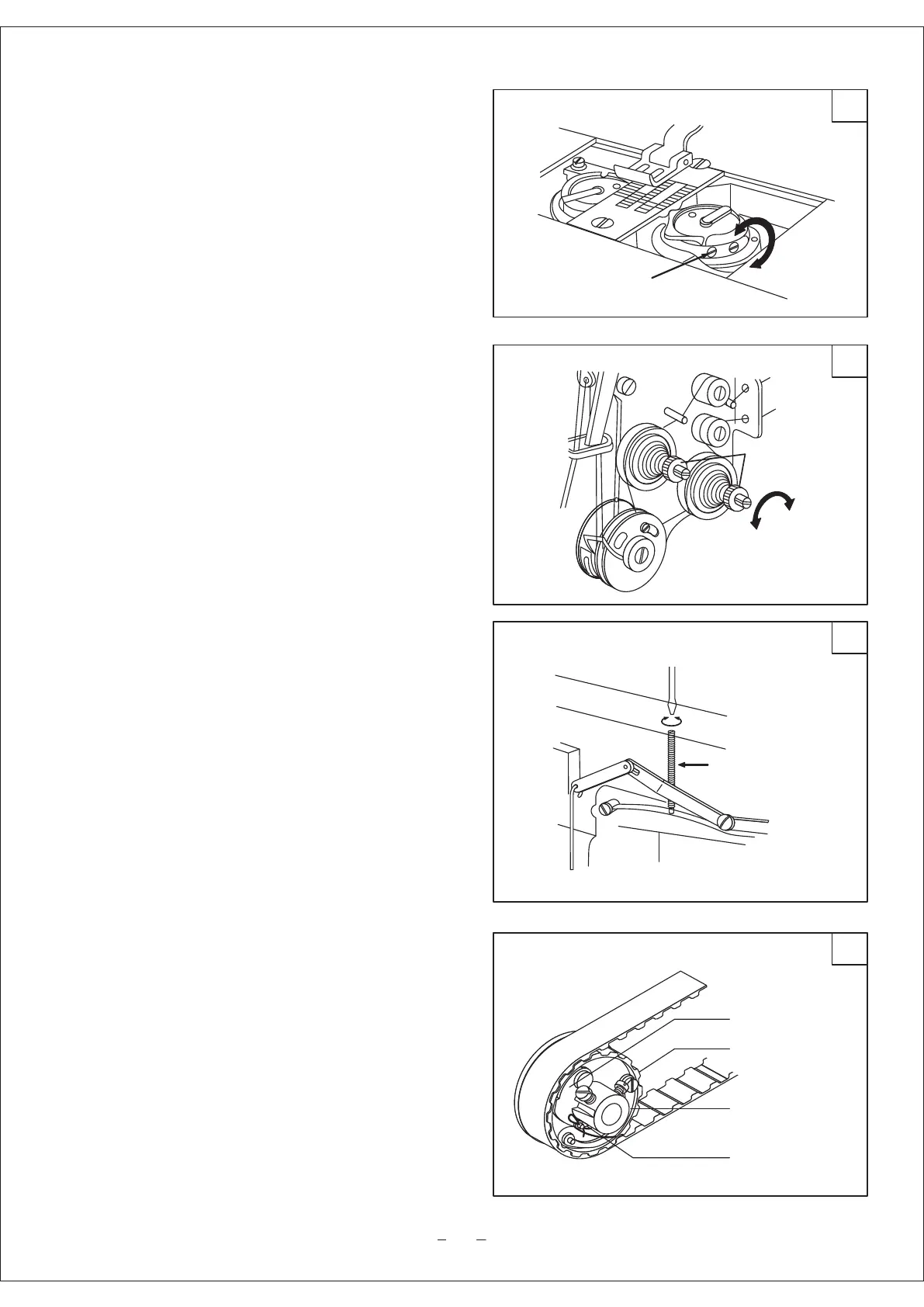

5.3 Safety clutch device

The safety clutch device is to prevent the hook and

teeth-belt from destroy when the needle thread is drawn

into the hook for abnormal load during the operation.

5.3.1 Function of the safety clutch device (Fig.28)

a. When the safety clutch device is working, the

teeth-belt will remove the load. The rock shaft stops

rotating., only the upper shaft rotates, then the machine

stops work.

b. Clean off the needle thread which is drawn in the hook.

c. Turn the shaft of the teeth-belt with hand to check if

the rock shaft can turn smoothly, then reset the safety

clutch device.

Needle thread tension adjusting screw

Loosen

Tighten

Strengthen

Weaken

Pressure adjusting screw

Safety clutch

Pulley

Belt shaft

Stop plate

Strengthen

Weaken

Needle thread tension

Loading...

Loading...